Metal tile is a unique material for roofing, with its help you can get a strong, beautiful and durable coating. It is not difficult to mount such a roof, and many home craftsmen take up the work themselves, but in order for the results to please, you need to know how to fix the metal tile correctly.

Metal tile is a unique material for roofing, with its help you can get a strong, beautiful and durable coating. It is not difficult to mount such a roof, and many home craftsmen take up the work themselves, but in order for the results to please, you need to know how to fix the metal tile correctly.

- General information about metal tiles

- General rules for the installation of metal tiles

- Features of installation of metal tiles with hidden fastening

- Fastening of metal tiles on the eaves and ridge of the roof

- How to install metal tiles around pipes and other obstacles?

- Mistakes that beginner roofers often make

- conclusions

General information about metal tiles

A metal tile is a roofing material made of steel sheets with a polymer coating. Thanks to special stamping, the material looks like natural tiles laid in rows.

It is customary to say that the transverse profile rows are waves, and the longitudinal profile is called rows. The distance between the rows is called the step of the metal tile.

The most common option is when the overall width of the sheet is 1180 mm, and the working width is 1100 (80 mm of the width of the material goes to overlap). The pitch of the metal tile, in most cases, is 350 mm.

The lower cut is located at a distance of 5 cm from the lower edge of the stamping, the length of the segment from the upper edge of the stamping to the upper cut depends on the length of the sheet, which is calculated depending on the needs of the customer.

Such metal tiles as Andalusia, Spanish dune, Spanish Sierra have a figured cut located 5 mm below the stamping line.

If the fastening of the metal tile is carried out correctly, then the joints of the sheets along the waves and rows will be absolutely invisible. The metal tile is mounted on pitched roofs with an inclination angle of at least 14 degrees.

Together with the metal tile, items such as:

- Roofing strips - cornice, ridge, valley;

- Flat sheets of metal with the same coating as metal tiles for the construction of aprons for pipes and expensive roofing elements.

General rules for the installation of metal tiles

Consider the general rules for fastening metal tiles:

- For cutting sheets of metal tiles, a tool that does not have an abrasive effect is used. These can be metal shears, saws with a circular cutter, etc.It is forbidden to cut sheets with a grinder, this tool leads to the destruction of the protective layers that protect the steel from corrosion.

- Installers must move carefully on the roof and wear soft-soled shoes. You need to step only into the deflection of the wave and into the places where the boards of the crate are located.

- During installation, the metal tile is fastened with self-tapping screws. It is necessary to use roofing screws (dimensions 4.8 × 35 mm, 4.8 × 28 mm) equipped with a gasket made from EPDM rubber. To prevent the self-tapping screws from standing out on the roof surface, their hats are painted in the color of the roofing material.

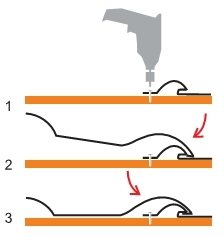

- When working, limit the torque of the screwdriver (it is more convenient to use a device with a rechargeable battery) so that after the pressing is completed, the rubber gasket is only slightly compressed. If the torque is insufficient, the required degree of sealing of the hole will not be achieved by compressing the gasket. If the torque is excessive, then there is a risk of the screw turning in the crate, which will cause the fastening to loosen. In addition, in this case, the gasket is likely to be deformed, which will reduce the life of the coating.

- It is very important that the fastening of metal tiles with self-tapping screws is carried out strictly perpendicularly, that is, the handed self-tapping screw must form a right angle with the surface of the crate.

- When attaching the sheet to the crate, self-tapping screws are screwed in at the place of wave deflection.

- The bottom sheet is attached to the initial bar with a step of the self-tapping screw through one wave.

- And how to fix the metal tile in places of vertical overlap? For this, short self-tapping screws (screw length 19 mm) are used, which fasten the sheets together. Screw the screws into the recession of the wave.

- Self-tapping screws are placed along the perimeter of the roof in the deflection of each of the waves. Next, the screws are staggered, screwing them into each lath.

- Consumption of self-tapping screws per square meter of coating - 8 pieces, when attaching accessories - three pieces per linear meter on each side.

- Accessories are attached with a screw pitch of 350 mm, each transverse wave. When fastening along the slope, the screws are screwed into the upper ridge, and then - through one wave.

- When making fasteners for metal tiles, it is necessary to immediately remove chips or sawdust formed in the process from the surface of the coating. To do this, you should arm yourself with a brush with a soft bristle. If you do not remove sawdust in time, they will quickly rust and spoil the appearance of the coating.

- If scratches or other damage to the polymer layer appear during transportation or installation work, then the defects must be immediately painted over with paint from an aerosol can. The same should be done with the places of cuts on the sheets. This will help prevent the onset of corrosion.

- Places of overlapping sheets are a vulnerable spot of the roof. Here, a capillary effect can occur, when water, having leaked, begins to rise above the level where the water flows. To avoid this undesirable effect, an anticapillary groove is made on the sheets, through which the water that has fallen under the sheet is drained. During installation, make sure that the anti-capillary groove of one sheet is covered by the next.

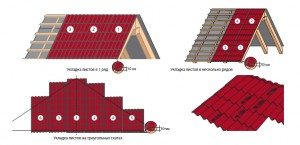

- And how is the metal tile fastened with multi-row laying? In this case, up to four sheets can be at the junction. If they are superimposed in the same row, a shift inevitably occurs. So on a cornice 10 meters long, such an offset can reach three centimeters. Therefore, sheets are laid with a slight turn clockwise if the anti-capillary groove is on the right side, and counterclockwise if the groove is on the left side of the sheet. The amount of displacement during rotation is about 2 mm.

- When laying a metal tile, the second and subsequent sheets can be located both to the right and to the left of the first, the scheme for fastening the metal tile is selected solely for reasons of convenience.

- It is recommended to start installation from the side of the house where there are no bevels, and there is no need to trim the sheet. Installation continues towards the junction formed by another slope, or to a valley located between adjacent slopes.

- When laying a sheet, the next or previous sheet completely overlaps the extreme wave of the adjacent sheet, closing the anti-capillary groove. When mounting with slipping a sheet, the edge of the next one is brought under the edge of the previous one. Thus, installation is somewhat easier than when overlapping from above, since the next sheet is fixed by the previous one, that is, slipping of an unfixed sheet is excluded. However, with this method of installation, the risk of damaging the coating of the metal tile increases.

- Regardless of the slope geometry, metal tile sheets are always aligned in a horizontal plane along the cornice line.Before fixing the metal tile to the crate, a block of three or four sheets is assembled, connecting them together with short self-tapping screws. In this case, the first sheet at the top point is fastened with a single screw. As a result, it is possible to rotate the resulting block relative to this screw, achieving perfect alignment with the cornice and side edges.

Advice! It is not recommended to collect more than four sheets in a block, as it will turn out to be excessively heavy, and it is fastened with just one screw. And it will be problematic for installers to work with such a heavy element.

- Let's consider how to properly fix the metal tile if the roof slope is triangular. In this case, it is necessary to make markings in advance, marking the center of the slope and draw an axis through it. Then the same axis must be marked on a sheet of roofing material. When mounting, the axes must match. The sheet is fastened with one self-tapping screw at the top point, further installation is carried out according to the same principles as on rectangular roofs.

- When installing metal tiles on triangular slopes, as well as in the region of valleys, sheets inevitably need to be cut. To make it more convenient, it is recommended to assemble an improvised tool, which roofers call "devil". To do this, take four boards, two of them are placed parallel to each other, the other two are perpendicular to them. In this case, the fastening should be hinged, and not rigid. The distance between the inner surface of the left board and the outer side of the right board should be 1100 mm, that is, it should be equal to the working width of the metal tile sheet. To perform the work, the sheet to be cut is placed on the "devil".One side of the device is laid on the edge of a slope or valley, and the other is used to mark the cut line. When using the device, you need to ensure that its transverse boards are located strictly horizontally.

Features of installation of metal tiles with hidden fastening

If the roof is covered with a material such as a metal tile with hidden fastening, then self-tapping screws with a press washer are used as a fastener.

But since fastenings on the surface of the coating of self-tapping screws will not be visible, you can use galvanized screws that are not painted in the color of the roof.

The main difference between the installation is that it is not necessary to make through holes in the roofing, as the self-tapping screw is screwed into a specially made groove.

Between themselves, the sheets are fastened by hooking mounting protrusions and grooves located at the edges.

The installation site of the self-tapping screw is hidden by installing the next sheet. That is, there are no fasteners and through holes on the surface of the coating. Of course, this option of roofing allows you to create an absolutely tight and, therefore, more durable coating.

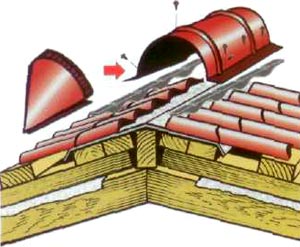

Fastening of metal tiles on the eaves and ridge of the roof

When making a cornice, as a rule, the sheets are laid so that the lower cut protrudes 40-50 mm beyond the edge of the plank. This is done so that rainwater directly from the metal sheet falls into the gutters.

So that the lower protruding cut does not sag, the extreme lath of the crate is made thicker than the rest by 15 mm.

A variant is possible when a special bar is attached to the eaves, which serves to drain water.

On the cornice, the fastening points of the metal tile are located along the cornice line approximately 7-8 centimeters above the location of the stamping, it is necessary to tighten the self-tapping screws in one wave.

If the length of the upper cut of the metal tile is more than 13 cm of the extreme stamping line, then a ridge board of increased thickness is additionally mounted above the upper board of the crate. At the same time, one must not forget to leave a ventilation gap between the upper elements of the crate of neighboring slopes of at least 80 mm.

Fastening is carried out in the deflections of the wave of the extreme row of stamping with a step through one wave. And if the cut length is more than 130 mm, then the upper part of the sheet is additionally strengthened.

How to install metal tiles around pipes and other obstacles?

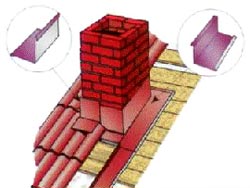

When bypassing vertical obstacles, it is important to be able to "intercept" the water flowing down vertically and distribute it to the sides. In addition, it is necessary to direct the water flowing down the slope located above the pipe, bypassing the obstacle.

Consider how to properly attach the junction bar to the metal tile and how to mount the inner and outer apron.

Advice! If the walls of the pipe are planned to be plastered, then this must be done before the roofing work has begun.

Additional sheathing boards must be installed around the pipe so that the coating is continuous. Sheets of metal tiles adjacent to the pipe on the left and right must be cut at a distance of at least 150 mm from the top surface of the pipe. The cut should be located 8 cm above the extreme stamping line. We begin to mount the apron:

- We mark the junction lines of the lower bar, they should be at least 15 cm above the surface of the metal tile.A strob is made along the line with the help of a grinder, into which the lower bar is inserted.

- First of all, the lower part of the apron is assembled, then the side ones.

- The lower apron is closed with sheets of metal, and the upper parts of the apron are mounted on top.

Advice! In order for the upper apron to lie more evenly, the sheets of metal tiles should be straightened with a mallet.

- The upper parts of the apron should extend beyond the cutting line of the sheets adjacent to the pipe by at least 20 cm. At the top, the apron part should have a flare pointing upwards.

- The details of the upper apron are interconnected according to the technology adopted in the performance of tin works. It is advisable to additionally use silicone sealant.

Mistakes that beginner roofers often make

First, you should choose the right fasteners for metal tiles. Often, when purchasing high-quality metal tiles with a service life of 50 years, novice roofers do not pay attention to the quality of fasteners.

As a result, instead of roofing screws with an ethylene propylene rubber gasket, screws with a washer made of ordinary rubber are purchased. Such a washer will quickly dry out and crack, and the tightness of the coating will noticeably decrease.

Secondly, inexperienced builders often make the mistake of screwing a self-tapping screw into the top of a wave using a long-threaded screw. In this case, it is not possible to achieve a sufficient fit of the washer, and when a significant force is applied, there is a risk of crushing the metal tile.

conclusions

Thus, the technology of fixing metal tiles is not particularly complicated. However, when carrying out roofing work, you must follow the installation rules and recommendations for installation given by the manufacturer.

Did the article help you?