Laying a metal tile with your own hands is a completely doable task. However, this will require desire and detailed instructions for action.

To achieve high-quality roofing, you will need to study many different kinds of subtleties, which we will share with you in this article.

Calculation of the required amount of material

Everyone has their own ways of laying metal tiles, but we will present you, in our opinion, the most optimal of them.

Before the beginning installation of metal tiles it will be necessary to calculate the required amount of material for roofing work.

The number of sheets of tiles is determined as follows:

- The number of rows of installation of metal tile sheets is counted. To do this, divide the length of the slope horizontally (maximum) by the useful part of the width of the sheet. The result is rounded up.

- To calculate the number of sheets in a row, the width of the slope is divided by the length of the tile sheet, excluding an overlap of 15 cm.

For the installation of a metal roof, it is recommended to use sheets with a size of 4-4.5 m, but in general their length ranges from 0.7 to 8 m.

In addition, the main method of laying metal tiles involves the use of additional elements, heat and waterproofing materials.

How to calculate them:

- Additional elements, as a rule, have a standard length of 2m. The calculation is carried out by measuring all sides of the slopes on which they are planned to be laid.

- Next, the amount received is divided by 1.9 (10 cm is left for overlaps) and rounded up.

- For the case with lower valleys, the result is divided by 1.7.

To find out the number of self-tapping screws required for attaching sheets, the total roof area is multiplied by 8 and the additional amount needed to attach additional elements is added.

Regarding waterproofing, it is supplied in rolls of 75 sq.m. One of them can cover 65 sq.m., and the rest will go to overlaps. In other words, the total area of \u200b\u200bthe roof is divided by 65 and rounding the result up, get the desired number of rolls.

erection truss system under a metal tile, fastening of a cornice and a frontal board.

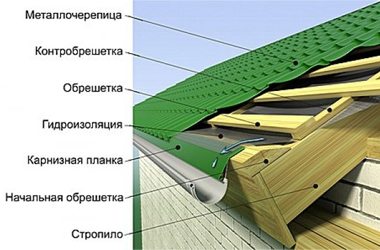

The technique of laying metal tiles will also require a certain structure of the roof truss structure.

Rafters with a section of 100 * 50 or 150 * 50 mm are installed under the metal-tiled coating. The step between them is arranged at 60-90 cm. They are made of wood with a moisture content of not more than 22%. Before installation, the bars are treated with an antiseptic composition. The roof pitch must not be less than 14 degrees.

Further, special grooves are cut in the rafters for laying a cornice board in them, which gives rigidity to the structure. Grooves are needed to maintain the height of the truss system. If long gutter hooks are used, special grooves for hooks are cut out in the eaves board, if they are short, they are attached directly to the frontal board. The frontal board is designed to perform a protective and reinforcing function and is attached to the ends of the rafters.

Lathing under the metal tile

When performing the installation of metal tiles, ventilation is provided under the roof sheets. To do this, the crate is placed on a counter-crate 50 mm thick, which is attached to the rafter beams over the waterproofing along their entire length. Due to the fact that the lower bar of the crate will be located under the upper step of the metal tile, its cross section is large for the height of the wave.

The laying of this bar is carried out parallel to the eaves. The second bar is fixed in increments of 28 cm, and the rest after 350 mm.Such a step will be correct if Monterrey metal tiles are being laid. For material from other manufacturers, the pitch may vary slightly.

Fasteners for ventilation pipes and other passage elements are left on the crates. For reliable fixation of the ridge, two additional bars of the crate are stuffed into the place of its fastening at a distance of 5 cm from the top. A continuous crate is arranged around chimneys, skylights, etc. When arranging gable overhangs, the boards of the battens are extended to the required length.

At their ends, from the bottom side from the ridge to the eaves, a bar is launched for reinforcement. The end board is attached to it. The board is necessary to close the crate and the fluctuations of the waves of the roofing material. From the end board to the rafter leg, connecting bars are installed, which are necessary for filing the overhang.

Installation of the cornice strip and the lower valley

- The eaves plank is attached to the cornice and frontal boards before mounting the sheets.

- As fasteners, galvanized self-tapping screws are used, screwed in in increments of 30 cm.

Advice!

To prevent rattling of the eaves strip during gusts of wind, it is set to tightness.

- The length of the overlap of the planks should be 5-10 cm.

- The lower valley (if necessary) is fixed with self-tapping screws along the formed wooden gutter in increments of 30 cm. Make sure that the lower edge of the valley is located on top of the cornice board.

- When joining the valley horizontally, the overlap is made at least 10 cm.

Advice!

In the future, a special sealant will be required between the valley and sheets of metal tiles.

Installation of sheets of metal

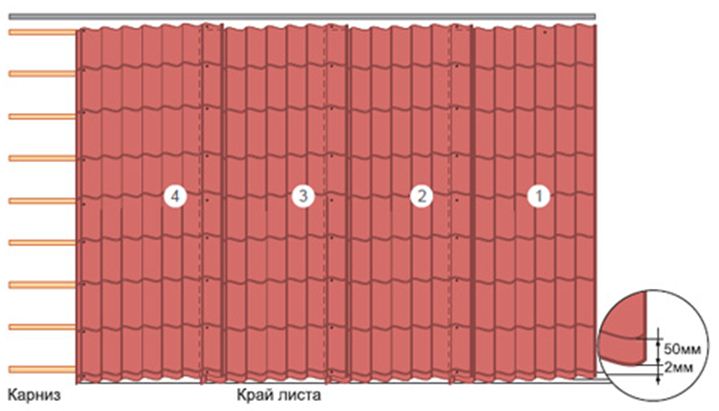

The technology of laying metal tiles - a video about which can be easily found on the network, is performed according to the following rules:

- To begin with, choose the side from which the flooring will be started.. Typically for many types of metal tiles no matter which side the laying will start from. But some types of material have a capillary groove, which serves to drain water and is located on the left side.

For this reason, if the installation is done from right to left, one wave of the previous one is covered with the next sheet. Thus, the capillary groove is closed from the left side. However, when installing in the opposite direction, it is necessary to adjust the next sheet to the wave of the laid one. If the capillary groove is located on the other side (this also happens), then, accordingly, the process is performed in reverse. - Each sheet is aligned relative to the cornice, regardless of the complexity of the slope. For the cornice, 5 cm of material is released.

- Next, fasten the sheets. In places where the sheet fits to the crate, a self-tapping screw is screwed into the deflection of the wave. From the side of the end board, sheets are attached to each wave. Self-tapping screws are screwed into the lower beam of the crate over the step through one wave. To the remaining bars of the crate, the sheets are screwed closer to the step from below. As a rule, for 1 sq.m. there are 6-8 pieces of self-tapping screws.

- Additional elements are screwed to each transverse wave or longitudinal wave crest. When tightening screws, use a screwdriver.

- If necessary, sheets of metal tiles with a hacksaw or metal shears or an electric jigsaw with a metal blade.

The following video will introduce the process in more detail: laying metal tiles.

Installation of other optional items

We examined how the metal tile is laid. Now, at the end of the roofing device, we will consider how you can install decorative and functional accessories - an end plate, an upper valley, a ridge.

The end plank is attached by means of self-tapping screws to the end board to the ridge from the eaves in increments of 50-60 cm. At the same time, the overlap of the planks is provided for no less than 10 cm. The upper valley is fixed with screws in such a way as not to touch the middle of the lower valley. Between the top element and the roofing sheets, do not forget about laying the seal.

The ridge or ridge bar is fixed with ridge screws into the upper ridge through the wave from each side. Plugs are installed from the ends.

Following the instructions we have voiced and choosing only high-quality materials for construction, a metal-tiled roof will delight its owner for decades.

Did the article help you?