Metal tile is a fairly popular roofing covering in our country. Having decided to buy it, do not forget that you need to purchase additional security items.

For example, snow retainers for metal tiles - installing them will prevent ice and snow from coming off the roof.

What you need to know before installing a snow retainer

Why are they so necessary?

Winters in Russia are harsh and unpredictable. They are characterized by a constant change of weather conditions - snowfalls, frosts, snowstorms and thaws, replace each other regularly. All this leads to the fact that masses of snow, a crust of ice and huge icicles are growing on the roofs of buildings.

This state of affairs poses a great danger, both for the roof and roofing, and for the health and life of people. Yes, and damage to cars parked near houses, during the descent of snow masses, in this case, has become commonplace.

Therefore, today snow retainers are an indispensable element of roof safety. They are installed above the entrance to the building, at each level of multi-level roofs, above all skylights and along the roof perimeter slightly above the eaves to distribute the snow load on the roof above its eaves. If the roof slope can be longer, then it is necessary to install several additional rows of tubular snow retainers on it (Footnote 1).

Modern snow retainers can be divided into two types of structures (Footnote 2):

- Structures that allow snow masses to pass through them.

- Structures that do not allow snow masses to pass through (snow barriers).

The purpose of the first type of structures is to gradually pass the snow masses through themselves and at the same time reduce the kinetic energy of the sliding snow mass to a safe level.

The purpose of snow barriers is to absolutely prevent snow masses from leaving the roof in any form.

Note!

As for the roof itself, on which snow masses grow, at the moment of their convergence, drains and the finish coat are most often damaged.

And these are unplanned financial expenses for their repair. Based on the foregoing, snow retainers are an indispensable element of a modern roof.

Installation technology

- First you need to choose the right type of supports and calculate the optimal distance between them. In this case, it is imperative to take into account possible power loads, the type of roof, the type and pitch of the crate, as well as the diameter of the rail. It should be noted that the expected load that a single support will undergo may depend on both its material and the method of fastening.

- If the roof is long and the slope is steep, then the supports are placed in two / three rows and are evenly distributed along the entire length - from the ridge to the cornice. Thus, the load will be uniform, over the entire area.

- High-quality snow retainers do not need to be treated with any protective coating - they are sold already galvanized and painted with anti-corrosion paint.

- Before installing additional roof elements, be sure to check the areas of future fasteners and make sure they are strong.

- Snow guards are placed above the external load-bearing wall, next to the roof eaves.

- Whatever the remoteness of the structure from the eaves, its fastening must be placed in place of the outer wall.

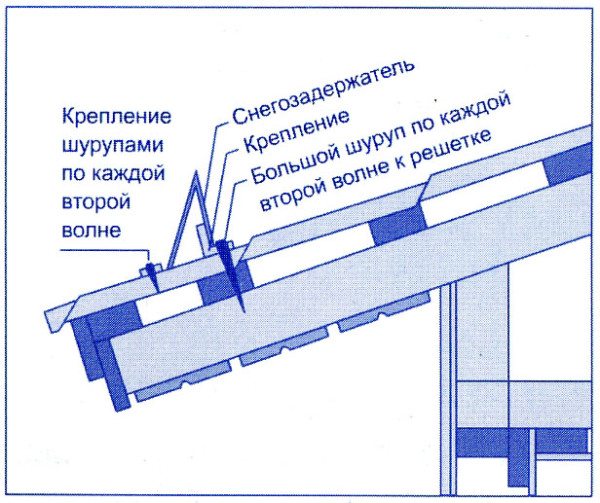

- If the roof is covered with profiled flooring, or metal tiles, the snow retainer must be fastened with self-tapping screws through to the crate.

- If the coating is folded, then the structure is fixed with bolts using a counter-element.

- The number of fasteners is calculated based on the type of lathing, slope and length of the roof slope.

- The step between the fasteners should not be more than 1m.

Consider all these questions at the design stage of the roof. If this was not done in time, solve all the tasks described before installing the roofing material. If necessary, place an additional support board on the crate to strengthen the structure.

Advice!

When choosing a company from which you will purchase snow retainers, take a closer look at the processing of protective elements.

You should not buy a cheap option, this is fraught with the fact that in two or three years rusty stains will appear on the roof itself and its additional elements.

As already mentioned, a quality product is coated with powder paint, and is also additionally treated with an anti-corrosion coating.

Types of snow-retaining roof elements

Snow guards are divided into the following types:

- tubular;

- lamellar;

- lattice (mesh);

- point.

The first three types are usually mounted on the roof cornice. The latter type is installed along the roof slope, in one or more rows.

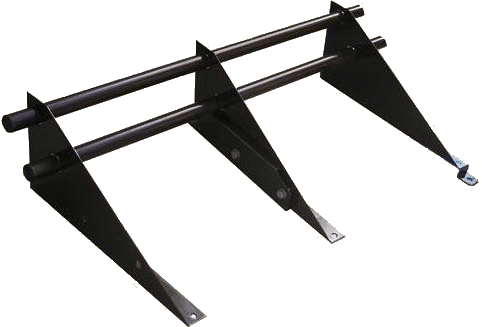

Tubular type snow guards

Tubular structures are the most common. They are used on metal tiles, profiled flooring, and seam roofing. The principle of operation of such structures is the portioned passage of snow between them and the roof.

Tubular type of snow retainers, can be located:

- in one line;

- in a checkerboard pattern;

- in one row;

- or several.

The choice of location depends on your wishes, as well as the functionality of the structure. As a rule, snow retainers are mounted along roof slopes, on the same center line with the eaves, as well as above footpaths, dormer windows, and the entrance to the building.

Note!

Fixings are located on the roof at 0./5/1m from the eaves.

Fasteners are best made in the area of approach under the roof of the outer wall.

It is very undesirable to fix the structure on the overhang of the eaves.

Mounting brackets, screwed to crate, directly through the roofing, with special roofing screws. It is recommended, when installing a tubular type snow retainer, to install an additional bar. It will interact with the reinforcing bar, and take over the bulk of the snow mass with it, thereby crushing it into small pieces.

Mesh and plate structures

The lattice snow retainer for metal tiles, in domestic construction, is used only on tiled roofing. An obstacle to snow, in this case, is a grid (grid) placed along the edge of the roof. Structures of this type are mounted using universal supports, which can either be nailed or suspended from the roof.

Plate elements are the most inexpensive option for a snow fence. They are very convenient during installation, but they cannot always cope with a large mass of snow.

Such structures are usually used on roofs with a slope angle of not more than 30º. They are placed on the second (bottom) wave of the metal tile, at a distance of 0.5 m from the roofing cornice.The upper edge of the structure is placed close to the step, and fixed with screws in each wave, in its upper part.

The joints of the structure must be treated with sealant. When such a need arises, the snow retainer is additionally reinforced with a special corner.

Installation of snow guards on metal roofing

For roofshaving a coating of metal tiles or profiled flooring, it is preferable to choose tubular or network snow retainers. They have proved themselves perfectly and guarantee the most complete and high-quality performance of the functions assigned to them.

Note!

The main advantage of tubular structures is that they allow snow and ice to pass between the pipes and the roof only in small parts.

This increases the life of the snow retainer itself, and also eliminates the likelihood of an avalanche of snow masses.

Installation of network structures is the best option for high roofs in the city. They also completely exclude any possibility of ice falling or snow avalanches.

Such snow retainers can be mounted both in one line and in a checkerboard pattern. If the roof slope is long, it is best to arrange them in several rows to provide increased reliability and ensure safety.

Tubular and network snow retainers are mounted using roofing self-tapping screws, 50 × 8 mm in size. The fasteners of the structures are fixed on the carrier crate at both ends. In the areas of fastening of the snow retainer, metal tiles must be fixed very securely on the base of the roof.Otherwise, the coating may not withstand an additional roofing element.

To make the fastening more reliable and tight, all holes in the roof finish must be sealed with special rubber.

Installation of snow retainers is not the most difficult stage of roofing work. In most cases, a set of additional elements is accompanied by instructions for their installation. The main thing is to carefully study it, and strictly follow all the recommendations.

Did the article help you?