One of the most practical, both in terms of financial costs and in terms of functionality, is corrugated roofing: the installation instructions for such a roof are quite simple, which means that almost everyone can mount such a roof.

One of the most practical, both in terms of financial costs and in terms of functionality, is corrugated roofing: the installation instructions for such a roof are quite simple, which means that almost everyone can mount such a roof.

Below we provide a recommendation for the independent arrangement of such a roof.

Roof decking: properties and benefits

In order to work effectively with this or that material, it is necessary to understand for yourself its main characteristics. That is why, to begin with, let's figure it out - what is corrugated roofing?

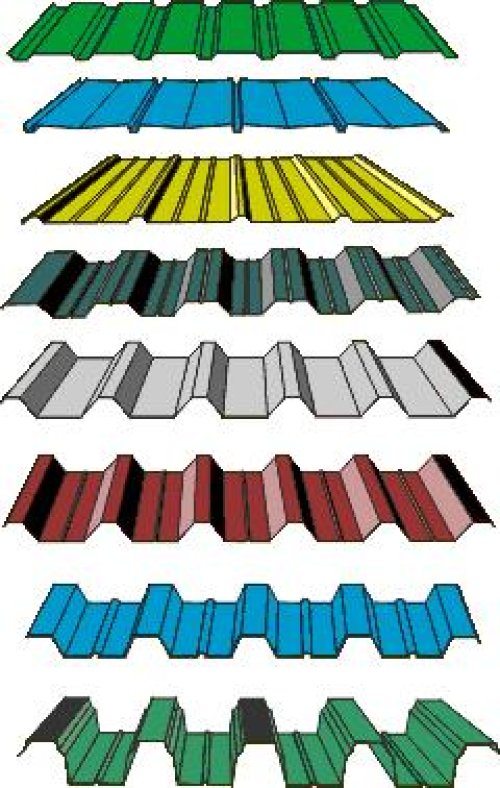

Decking is a material that is made from steel sheet by cold stamping. On a steel sheet with a thickness of 0.5 - 1.2 mm, trapezoidal waves are formed, which act as stiffeners.

The performance characteristics of the corrugated board depend on the thickness of the metal, the configuration and size of the stiffening ribs - the thicker the metal and the deeper the stamping profile, the stronger the roofs being built from the corrugated board will be.

To protect the metal from corrosion due to contact with atmospheric moisture, the corrugated board is covered with a zinc, aluminum-zinc or polymer coating. A combination of these coatings is also possible: today you can find galvanized corrugated board, which is coated with a decorative polymer on top of the galvanized layer.

Why is corrugated board so popular as a roofing material?

There are several explanations for this:

- Firstly, corrugated roofing has high performance: it is resistant to mechanical damage and weathering, and also retains an aesthetic appearance for a long time.

- Secondly, the advantage is a fairly simple installation - roofing corrugated board is easily laid and fixed on the roof slopes, while it is quite easy to equip a reliable and airtight roof.

- Thirdly, the roofing corrugated board has a small mass, which greatly facilitates both the preparation for installation (the requirements for the strength of the truss system and the lathing are significantly reduced), and the installation of the corrugated roofing itself.

Also, one should not forget about the economic component. If you need a practical, but at the same time inexpensive roofing, corrugated board is one of the best options.

Preparation for work

One of the advantages of corrugated board is a wide range of standard sizes of corrugated roofing boards available on the market. You can always find a material that will suit you in terms of the configuration and size of the stiffeners, color, and most importantly, the size of the corrugated sheets.

For the arrangement of the roof, it is best to use sheets of corrugated board, the length of which is equal to or slightly greater than the length of the roof slope. In this case, the roof is obtained without transverse joints and overlaps, which significantly increases its waterproofing characteristics.

Also, when using solid longitudinal slabs, the calculation of corrugated roofing is greatly facilitated: to find out the number of sheets required for purchase, simply divide the width of the slope by the width of one corrugated sheet.

Note! Most decking manufacturers list both the nominal (geometric) width and the effective (overlapping) width. Naturally, when calculating the roof, you need to focus on the second digit.

Sometimes, when preparing for roofing work, it becomes necessary to cut the roofing corrugated board: the dimensions of the sheet may be larger than required, or it is necessary to cut a groove for a chimney, antenna, etc.

To cut corrugated board you will need:

- For corrugated board on a steel base up to 0.6 mm - metal shears (or electric shears, if you need to make a large cut, and at the same time get a clean cut line)

- Hacksaw with fine teeth

- Electric jigsaw with metal blade

- Circular saw with fine teeth

Note! The use of a grinder with an abrasive wheel for cutting corrugated board is strictly prohibited.

Lathing under the roofing corrugated board

If roofing corrugated board is used as a roofing material, it is installed on a crate, equipped either directly on top of the rafters, or (if the roof is insulated) - on top of the insulation and waterproofing.

For the crate we need:

- Beam 50x50 mm

- Board 32x100 mm

- Sheets of oriented strand board or moisture resistant plywood 10 mm

The crate can be either solid or thinned. The thinned crate is installed in increments of 50 mm, however, even in this case, in particularly problematic places (around chimneys, on skates, ribs and in valleys), we equip a continuous crate.

Before arranging the crate, we treat all wooden parts with antiseptics that prevent wood decay and fire-fighting compounds.

On top of the crate, you can lay a lining - a superdiffusion membrane. Such a membrane prevents the formation of condensate, which adversely affects durability. do-it-yourself corrugated roofs.

The membrane is fixed to the logs or to the crate with special nails with a wide, tight head.

We raise the corrugated board to the roof

When the corrugated boards are cut to size and the crate is fully equipped, you can proceed directly to such a process as installation of a standard profiled sheet on the roof.

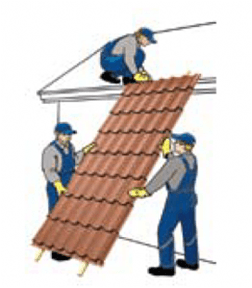

However, sometimes difficulties arise in order to raise the roofing corrugated board to the roof: installation is often carried out by two or three people, and for comfortable work it is trite “not enough hands”.

If you work with a small team, then you can use the logs to lift the corrugated board to the installation site. We install the lags in such a way that at one end they rest against the ground, and at the other end against the eaves of the roof slope.

The distance between the lags should be slightly less than the width of the corrugated board. With this system, two people can lift roofing profiled sheet for fixing - fortunately, the small specific gravity of the material allows this.

As a log, you can use an ordinary staircase without a railing - so your partner, who feeds sheets of corrugated board from below, will be even more comfortable.

Note! In order to prevent accidents, you should not lift the corrugated board (and indeed do roofing work) in windy weather.

Installation and fixing of corrugated board

The technology of corrugated roofing is as follows:

- The corrugated board is attached to the crate using special white metal screws with a drill. The most popular fastener sizes are 4.8x20 mm and 4.8x35 mm. The self-tapping screws have a hexagonal head and are equipped with a neoprene sealing gasket.

Note! This technology of roofing from corrugated board does not imply excessive tightening of self-tapping screws, since when the gasket is re-sealed, its waterproofing characteristics deteriorate.

- We start fixing the corrugated boards from one of the ends of the slope, while the side overlap should be half the wave of the profile. For gentle slopes with a slope angle of 8 - 12 the optimal overlap is one and a half waves - in this way we minimize the likelihood of leakage in the joint area of the plates.

- We fix the corrugated board with a self-tapping screw in the lower part of the wave. In the upper part we fasten corrugated boards in the overlap area, as well as ridge elements. To fix the corrugated board in the upper part of the wave, we use longer self-tapping screws - 80 mm or more (depending on the profile of the wave).

- Joints (both longitudinal and transverse) are additionally sealed with bituminous mastic or self-adhesive sealing tape.

- We strengthen the gable parts of the roof with the help of wind pads, the main task of which is to protect the corrugated board from wind blowing and destruction. We fix the overlays with self-tapping screws in increments of 20 cm.

- Separately, we block the valleys, ribs and nodes where the roof adjoins vertical surfaces. For overlapping, we use a metal profile, additionally sealed with bituminous mastic.

Roofing from corrugated boards is a good choice in terms of efficiency, reliability and practicality of the erected roof.

And even if you do not deal with the arrangement of the roof on your own, but use the services of professionals, knowing what a corrugated roofing device is will be very useful to you, since you can control the quality at any stage of work.

Did the article help you?