Recently, such material as corrugated board is gaining more and more popularity in construction. This article will talk about what corrugated board is, which brand is better to choose, as well as how do-it-yourself corrugated board is laid and mounted on the roof.

Recently, such material as corrugated board is gaining more and more popularity in construction. This article will talk about what corrugated board is, which brand is better to choose, as well as how do-it-yourself corrugated board is laid and mounted on the roof.

The professional flooring represents the material made by stamping from sheets of galvanized steel. Stamping gives the material longitudinal ribbing, drastically changing its flexural strength, while the weight remains unchanged.

Thanks to this, knowing how to properly lay corrugated board, it can be used both in the construction of wall enclosing structures and roofing.

Installation of corrugated board on the roof has its own characteristics.The covered roof can be either single or gable, and shed roofs can be either flat or have a certain slope.

They produce corrugated board as in a "pure" form, i.e. only with galvanization, and with an additional protective layer of polymers or enamels.

Next, instructions will be given for laying corrugated board, but first you need to figure out how to choose the right material.

Choosing a brand of corrugated board

Marking of corrugated board is carried out depending on the purpose and strength of the sheet. Typically, the lineup starts with C-8 sheets, and ends with H-158 or a higher grade.

Additional indices can be used in the brand, which indicate parameters such as wave pitch or profile shape. The European classification marks analogues of Russian corrugated board with designations, at the beginning of which RAN or T is indicated.

Knowing how to properly lay corrugated board, a specific profile for laying is chosen in accordance with the planned roof structure, adhering to the rule: the more roof pitch, the lower the brand of material:

- For grades from S-8 to S-25, the roof angle must be at least 15 degrees;

- For more durable brands - over 6 degrees.

In addition, the following characteristics affect this parameter:

- Profile depth;

- Profile form;

- Corrugation repetition period (drawing).

In addition, some types of sheets are equipped with grooves for water drainage, as well as concave or convex stiffeners.

Before laying the corrugated board, it is necessary to carry out a crate, the step of the bars of which depends on the brand and the design load of the profile: the higher they are, the less often the bars can be laid.

For example, before installing the S-8 grade corrugated board, a crate is installed with a beam pitch of 50 centimeters, and when installing grades H-153 and higher, the beam pitch is up to 90 cm.

For all brands of corrugated board, a fairly wide range of sizes is presented:

- The length of the sheets reaches 12 meters;

- The width of the sheets can be from 600 to 1250 mm;

- Sheet thickness - in the range from 0.3 to 1.5 mm.

The rules for laying corrugated board recommend choosing the length of the sheets in such a way that it is able to completely cover the entire slope, including the roof overhang.

Installation of corrugated board

After all the necessary calculations are completed, you can proceed with the installation. In this case, the order of laying corrugated board should be observed:

- First they arrange on the lags roof lathing from boards with a section of 100x32 mm, or from special steel girders with the same strength. In this case, the logs should protrude 200-300 millimeters beyond the cutoffs of the floor slabs, and the ends of the logs are sewn up with a special strip for cornices. The last board of the crate is mounted along the edge of the log.

- For various curly elements, such as valleys, gutters, snow guards, etc., boards are additionally installed, the shape of which repeats the shape of the elements themselves. At the same time, it is important to ensure that the width of the boards allows a sheet of corrugated board to enter them at least 25 millimeters above the style.

- An end board is attached to the last lags from the side walls.

- Perform a roofing cake, the layers of which should be arranged in the following order, starting from the inside:

- Vapor barrier film;

- thermal insulation material;

- Waterproofing layer in case of a slight roof slope;

- Sheets of corrugated board.

Important: vapor barrier is designed to prevent the penetration of moisture from the interior into the insulation material. . The technology of laying the corrugated board provides for the installation of a vapor barrier along the crate, while ensuring a slight sagging of the film, which provides additional ventilation.

- Perform a very tight laying of sheets or, in the case of rolled materials, insulation tapes. Laying is carried out perpendicular to the direction of the profiled sheets.

- A waterproofing film is laid, instead of which bituminous mastic or other similar material can be used.

Roof deck fastening

When performing work at height, various safety measures should be observed to prevent both a threat to the life and health of workers and damage to the roofing material:

- Use safety ropes and mounting belts;

- Depending on the slope of the roof and other factors, equip protective fences;

- Walk on the roof in non-slip soft shoes, on which there should be no elements that could damage the protective coating of the sheets. If the coating is damaged, it should be repaired with a special compound.

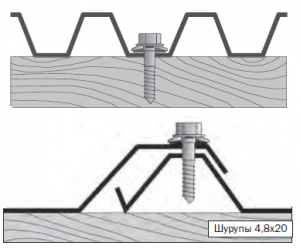

When performing installation, it is important to know how to properly screw the corrugated board. Sheets are fastened with self-tapping screws, less often with nails with a rubber or polymer gasket placed under the cap.

The following tools can be used to cut the coating and its components:

- Hacksaw with fine teeth;

- Carbide high speed circular saw;

- Tin scissors;

- Special electric cutter.

Important: in no case should you use abrasive tools, such as ("grinder"), to cut corrugated sheets. When using such a tool, high temperatures occur, leading to such adverse effects as overheating of the steel, making it brittle and resistant to corrosion. In addition, the protective zinc coating and the additional insulation layer applied to it are destroyed. All this together reduces the life of the entire roof several times.

Sheet fixing point

The main nuances of the installation of corrugated board:

- Start laying the material on the roof from the bottom corner of one of its ends. If it is necessary to lay several rows of corrugated board, the bottom row should be laid, leaving an indent (overhang) from the cornice strip, which is 35-40 millimeters. The sheet is fastened to the last plank at the edge of the roof along the bottom of every second wave.

- On the sides of the building, the end boards are sewn up with a wind corner after the entire end row or sheet is finally fixed. Here, the installation of corrugated board can be done both in transverse and longitudinal rows.

- The overlap of sheets is performed as follows:

- In the vertical direction, the top sheet must overlap the bottom sheet by at least 200 millimeters;

- In the horizontal - the top sheet should go to the bottom one by one wavelength in the case of using a gasket-seal, and by two wavelengths - without a gasket.

Useful: with a roof slope exceeding 16 degrees, the sealer can not be used, even when entering a single wave length.

- Fastening of sheets laid from the edge, starting from the center of the “free” side of the edge, is carried out using one self-tapping screw. Next, the adjacent sheets are laid, their alignment and fastening is similar to the first.

- After the laying of all adjacent sheets is completed, the first sheet is fastened in the following way: the longitudinal connection is made along the crest of the wave, the pitch is 500 mm, and the vertical joints are fastened in each day of the wave.

- The sheet is fastened to the crate by means of self-tapping screws to the bottom of the wave. For each square meter of the covered roof, 4-5 self-tapping screws should be used.

- After the main sheet of the coating is fixed, the end and ridge strips are installed. At the same time, ridge strips are not compacted, and gaps must remain in the profile relief to ensure ventilation of the space under the roof.

- The final stage of covering the roof with corrugated board is the installation of junctions to the walls of neighboring buildings (if they are higher than the covered roof), as well as chimney outlets and similar elements.

In this article, material such as corrugated board was considered - how to lay and how to choose the right brand, what subtleties should be considered when installing a corrugated board coating.

Did the article help you?