This article will talk about what corrugated board is, how it is used, what varieties exist and how the material is installed on the roof.

This article will talk about what corrugated board is, how it is used, what varieties exist and how the material is installed on the roof.

Decking is a roofing material in the form of profiled sheets of galvanized steel, which is covered with a polymer coating depending on the manufacturer - polyester, plastisol or pural.

Roof decking in fact, it can be compared with metal tiles, since both materials are produced by cold rolling galvanized steel coils coated with polymers.

This technology allows you to maintain the integrity of the coating of profiled sheets.The question often arises - what is better slate or corrugated board, the quality of the material should be assessed depending on the specific building under construction.

The main difference between corrugated board and metal tiles is in the pattern.

The metal tile is an imitation of ceramic tiles traditionally used for roofing, and the corrugated board looks more like slate than is used, for example, when slate is replaced with corrugated board.

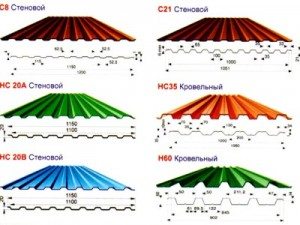

At the same time, the corrugated board waves can be given different shapes and heights, and the corrugations are made in the form of various shapes, such as a trapezoid, a rectangle, a sinusoid and more complex ones.

The use of corrugated board

In accordance with the application, there are several types of corrugated board:

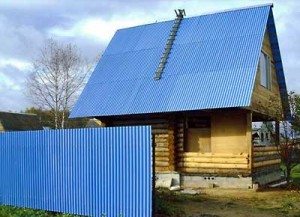

- Roofing, used to cover roofs;

- Wall, used when facing the walls of buildings;

- Bearing corrugated board - used in the rapid construction of non-residential facilities, such as shops, stalls, kiosks, etc.;

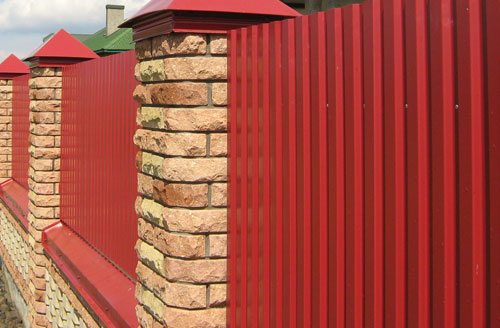

- Decking for fencing and fences;

- Decking for making fixed formwork during the construction of fairly large facilities.

Useful: when using a load-bearing corrugated board, the construction of objects is carried out according to the principle of sandwich panels, when the corrugated board is a load-bearing structure on one side and a cladding material on the other. A layer of heat-insulating material is laid between two layers of corrugated board.

Rolled steel is used for the manufacture of corrugated board, so the length of the sheets varies depending on the dimensions provided by the customer.

When calculating the length of corrugated sheets used to cover the roof, not only the length of the roof slope, but also the length of the visor should be taken into account.

Important: regardless of the material used, for example, slate or corrugated board, it should be ensured that it protrudes beyond the boundaries of the roof slopes by a distance of about 40 cm.

The width of the sheets of corrugated board is set by the manufacturer, usually it ranges from 980 to 1850 mm. In this case, it should be taken into account that the useful width of the material is approximately 40-80 mm less than its actual width.

This is due to the requirements for laying the profile: sheets of corrugated board must be overlapped, and the overlap must be equal to the length of one corrugation.

Decking usually has a standard thickness (0.5; 0.55; 0.7%; 0.8 or 1 mm), which is chosen depending on the area to be covered and the climatic conditions of the area.

So, in the middle zone of our country, sheets with a thickness of 0.5 and 0.7 millimeters are most widely used.

The height of the corrugated board, that is, the distance between the two extreme points of adjacent corrugations, directly affects the volumetric appearance of the building or roof where the material is used. Depending on the pattern of the material, the height can be from 15 to 130 millimeters.

Advantages of corrugated board

We list the main advantages of corrugated board:

- Decking is a fairly light material, so its delivery to the place of application is greatly simplified, and its cost is reduced;

- Double protection against negative environmental influences (galvanization and a durable polymer coating) ensures the durability of the material, makes it resistant to corrosion and significantly increases its strength, allowing it to withstand significant loads (for example, hail);

Useful: the guaranteed service life of corrugated board is 50 years.

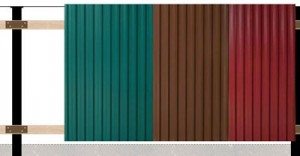

- The polymer coating of the profile can be painted in a variety of shades, which allows you to choose the most suitable color from 30 different options offered by manufacturers. To select the color of the corrugated board, the RAL scale is used;

- When choosing from two materials - corrugated board or slate, it should also be taken into account that, thanks to the polymer coating, the corrugated board is not subject to fading under the action of sunlight and its color will be as bright as two years after the construction of the building, and after thirty or fifty years;

- The structure of the profile and the various features of the installation of the material (sheets overlap each other by one wavelength or corrugations) prevent the roof from leaking under any conditions;

- Installation of corrugated board for both roofing and load-bearing structures or walls is quite simple and convenient. This allows you to perform the installation of corrugated board yourself without special skills, which saves on the involvement of specialists;

- Roofing profiled sheet - a fairly cheap material, its price is much lower than the prices of other roofing materials, including metal tiles;

- The benefit from the use of corrugated board increases due to its high durability.

Components and accessories for corrugated board

When buying corrugated board, you should also purchase all the components necessary for its installation, made of the same high quality galvanized steel as the material itself, and covered with the same polymer coating.

The color scheme of the components coincides with the material itself, which allows you to give a holistic look to the finished structure.

In different situations, various components are used, which should be selected in advance depending on the design plan:

- The ridge bar is designed to protect the upper horizontal edges of the slope or the site of a slope fracture.

- The end plate closes the end part of the roof. It is laid with an overlap of at least one full profile length (50 millimeters).

- Valleys installed at the internal joints of roof slopes, while the gaps between these joints are sealed by sealing. The joint is fastened in the lower corrugations using self-tapping screws, the pitch between which is 300 mm.

- Internal corner trims that perform a decorative function. These strips are attached to the corner with self-tapping screws, without requiring a sealant.

- The outer corner strips are designed to protect the joint from water penetration. Fastening is carried out with self-tapping screws without the use of a sealant.

In addition to the components and the profile itself, installation will also require accessories such as self-tapping screws, hydro- and vapor barrier films and insulation material.

The use of corrugated board for roofing

Before ordering corrugated board, you should correctly calculate the required amount of material.The length of the sheets is calculated as the sum of the length of the slope edge and the length of the protruding part of the cornice, which is usually 20-40 centimeters.

The number of sheets is calculated by dividing the width of the roof by the width of the profile (useful), rounding the result up to a whole number.

Important: the recommended slope of the roof should be from 80 degrees, that is, the height of the roof is less than half the width by seven times.

You should also carefully consider the roof ventilation system, placing the ventilation holes as close to the ridge as possible.

Consider the main stages of roofing with corrugated board:

- A film of vapor or waterproofing is attached to the rafters. Waterproofing is used with a relatively small slope of the roof, in which moisture can penetrate into the under-roof space. At large angles of inclination, it is enough to lay only a vapor barrier.

- Fastening sheets of corrugated board is carried out, starting from the end of the roof. In this case, it is necessary to ensure that the sheets are located strictly perpendicular to the ridge, so as not to subsequently re-measure. When laying each subsequent sheet, an overlap of at least 50 mm is observed, that is, half or a full wave (two corrugations).

- If a longitudinal overlap is performed, its value is at least 200 mm. At the overlap point, the sheets are necessarily fastened, and a sealant is laid between them.

- Fastening sheets of corrugated board to the film is carried out using special self-tapping screws equipped with seals and press washers. Self-tapping screws are installed in the lower corrugation of the profile.

Important: fixing the corrugated board with nails is carried out only in the upper corrugation of the profile.

- After the corrugated board is installed, it is insulated from the inside, and the plates of the insulating material must lie down for 24 hours in an open package before they are installed. In central Russia, the thickness of the insulation is usually 150 millimeters.

That's all I wanted to talk about how to choose corrugated board and how it is applied. This material has already gained great popularity, which will only grow over time due to a number of its advantages and low price.

Did the article help you?