If you decide that your roof will have a flexible roof installed on your own, this article is for you. In it we will tell you what it is, how to do it and in what sequence.

If you decide that your roof will have a flexible roof installed on your own, this article is for you. In it we will tell you what it is, how to do it and in what sequence.

The roof is flexible (soft roof) it is made of bituminous tiles, flexible tiles, roofing tiles, shinglas and shingles. We will consider the example of flexible tiles.

Flexible tiles - flat sheets, 1x0.33 m in size. Made of fiberglass or felt (base), which is impregnated with bitumen. The base connects two layers of modified oxidized bitumen with polymer additives.

Outside the tile is covered with a mineral crumb. Bituminous impregnation provides the tiles with flexibility, strength and resistance to deformation.

Mineral chips provide protection from weather conditions and UV rays, and also creates the color of the tile.On the inside, the tiles are covered with a special adhesive layer, which is covered with a protective film (self-adhesive) or silicon sand (traditional).

The scope of flexible roofing is different:

- On pitched roofs roof pitch angle at least 12;

- For the reconstruction of old roofs (can be laid on old roofing in problem areas) and the installation of new roofs;

- For complex roofs.

What are its advantages over other roofing materials?

- Noiselessness. During rain, unlike corrugated roofs, you will not hear the sounds of falling drops.

- Profitability. On the roofs of a complex configuration, and on ordinary ones, there is practically no waste.

- It is heat and sound insulator.

- Resistance to chemical acids and biological organisms (moss, fungi).

- The material is not subject to corrosion and decay.

- Waterproof.

- Serves as a dielectric.

- There is no need to install additional snow guards.

- Does not change color under the action of sunlight and does not require subsequent painting.

- Temperature resistance. Not afraid of sudden changes, copes well with both high and low temperatures.

- Elasticity. The flexible tile perfectly bends and any roughnesses are not terrible to it.

- Has a small weight.

- Easy to install.

- Withstands strong gusts of wind.

- The service life is about 50 years.

Flexible tile has a different geometric shape of scales, from a wave to a hexagon. The color range is great, you can choose almost any color for your roof.

There are many manufacturers, their products may differ in shape, price and quality.Speaking about the pricing policy, I would like to note that this type of roofing material has a relatively low price compared to other coatings.

Advice! Before buying material, it is recommended to consult with experts or read the reviews and comments yourself on the Internet or in print. It is advisable to learn as much as possible about the manufacturer, as well as correctly calculate the required volumes of material.

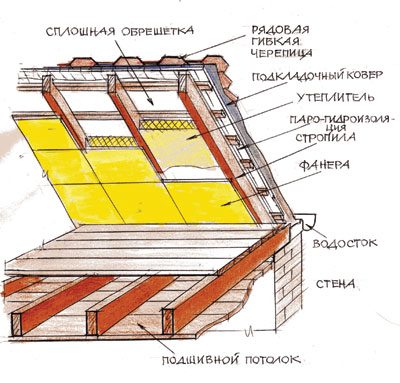

Roof device

The device of a flexible roof should include a set of measures. In order for the coating to last for a long time, care must be taken to create suitable temperature conditions and ventilation.

Work should be carried out at a temperature of at least +6 degrees, if this is not possible, the material is stored in a warm room, and taken out to the roof in small batches.

When installing, the main thing is to follow all the rules and the sequence of work. Experts do not recommend using tiles with different release dates and batches. This can make it difficult to achieve the same color throughout the entire roof.

Before starting work, you should prepare and purchase materials and tools. For installation you will need the following:

- Flexible tiles.

- Lining carpet. If the roof is laid from scratch, rolled bituminous material is used for these purposes. When repairing, a roofing material laid earlier can serve as a lining carpet.

- End carpet. A bitumen-polymer material is used, which acts as a waterproofing at the junction with vertical surfaces and at roof breaks. For its installation you will need a sealant or mastic for the roof.

- Adjacency plank. It will attach the valley carpet to vertical surfaces.

- Cornice plank. Protects the edge of the base from moisture and strengthens the eaves.

- Front plate. Reduces wind loads and protects the edge.

- Roofing and ordinary galvanized nails for installation.

- Bituminous roofing mastic or sealant.

- Building hair dryer and a knife with a hook-shaped blade for cutting tiles.

Now you can start installation.

Installation of flexible tiles

Work begins with the preparation of the foundation. A solid crate is attached to the rafters.

For these purposes, you can use edged coniferous wood boards with a thickness of at least 30 mm, OSB boards or moisture-resistant plywood. They are attached with self-tapping screws.

Advice! Before starting work, all wooden surfaces and materials are treated with a special protective and fire-resistant solution.

The next step is ventilation. For its normal operation, three conditions must be met:

- Provide openings for air inflow from the outside (external). For this brie sheathing of the cornice boxes should use soffit strips.

- Make exhaust holes. For open spaces between rafters - aerators, for closed ones - a ventilation ridge.

- Channels for air circulation. Their minimum height must be at least 50 mm, with a slope angle of more than 20if the angle is smaller, the height of the channels can reach up to 80 mm.

Now you should mark the roof. To do this, vertical and horizontal lines (guides) are drawn, along which the tiles are aligned.

They should not be taken as a guide for installation, they are only needed for alignment.The step of the vertical lines will be equal to the width of the ordinary tiles, and the horizontal lines to the distance between each 5 rows.

After that, you can start laying the lining carpet. It spreads over the entire surface of the roof. Start laying from the bottom, parallel to the overhang and gradually rise up.

Each subsequent strip overlaps the previous one (10 cm). Installation is carried out with roofing nails, the interval between them is 20 cm.

At roof slope over 18, it is allowed to lay the lining carpet not over the entire roof, but only on the valley, along the end parts, ridges and cornices. It is also necessary to creep in places where windows and pipes exit, junctions.

Advice! Installation of downspout fixtures, for some types of roofs, must be completed before laying the lining.

The next stage of work will be the installation of cornice and gable trims. Eaves are fixed with roofing nails every 10 cm, in a zigzag pattern. Planks are mounted with an overlap (2 cm). Gables protect the edges of the battens. The principle of installation is similar to the cornice strips.

To prevent water from penetrating through the valley inside, it is recommended to additionally lay one more layer in these places.

This is done as follows: bitumen-polymer material is rolled out. Its edges are fixed with bituminous mastic and roofing nails.

Nails are placed at a distance of 2 cm from the edge of the material and at intervals of 10 cm. It is worth noting that the material for the valley carpet should be chosen in accordance with the color of the main roof (flexible tiles).

The installation of tiles begins in the same way from the bottom (from the eaves). The distance from the cornice is 1-2 cm, the tiles are glued end-to-end. To do this, remove the protective layer from the back of the material.

To lay ordinary tiles, the following steps should be performed: the lower, protective layer is removed and the tile is glued on top of the eaves (1 cm should remain from the edge of the tile).

The joints of the cornice tiles must be completely closed ordinary. The tiles are stacked on top of each other, after which each should be fixed with 4 nails.

Each subsequent row is placed slightly above the cutouts of the previous row. On the end parts, the excess is cut off with a knife, the edge is glued with mastic at a distance of at least 10 cm from the end.

Ridge tiles are made from eaves. It is cut into three parts and glued with an overlap (5 cm), then nailed, two on each side.

Connection points with vertical surfaces are mounted in the following order:

- Planks are fastened (slats 50x50);

- A lining carpet is laid on them with the help of mastic;

- Then comes the ordinary tile tile, the edges are wound (at least 30 cm) onto a vertical surface and fixed with mastic;

- The junctions are closed with a metal apron, which is fastened with silicone sealant.

As you can see, the installation of a flexible roof does not require special skills and tools. The main thing is to strictly follow all the rules and technologies and you will have a warm and beautiful, reliable roof.

Did the article help you?