Ruberoid roofing is popular due to its low cost, ease of installation and durability (if laid in several layers). How this is done and which roofing material to choose, you can find out by reading our article.

Ruberoid roofing is popular due to its low cost, ease of installation and durability (if laid in several layers). How this is done and which roofing material to choose, you can find out by reading our article.

Ruberoid has been popular for a long time. Especially often roofing with roofing material is done on small houses, baths and cottages. This material has a low cost in comparison with corrugated boards and tiles, and is therefore more affordable.

In addition, roofing material can be used on both flat and pitched roofs. What does he represent?

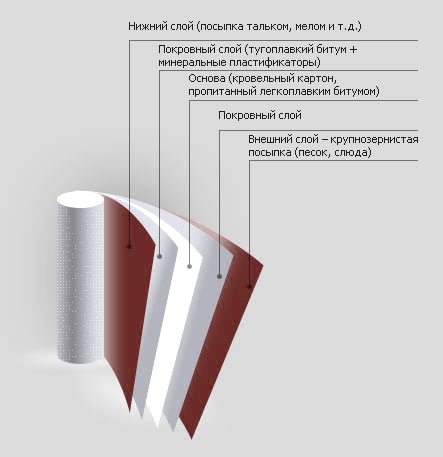

Ruberoid is a soft roofing or waterproofing material. It is made from roofing paper impregnated with petroleum bitumen.

In the future, it is coated on one or both sides with refractory bitumen with additives and fillers.This material is used for the lower and upper layers of the roof, waterproofing building structures and foundations.

It is conditionally possible to divide the roofing felt into 4 generations:

- Simple rolled roofing material (glassine, roofing material). On a cardboard base impregnated with bitumen, a coating composition and sprinkling are applied. Installation is carried out manually, the minimum number of layers is 3-5, the service life is at least 10 years.

- Built-up roofing material (rubemast). The laying of the roofing carpet takes less time than the first generation materials.

- Currently, in addition to traditional cardboard, a fiberglass or synthetic base is used. This makes the roofing material more durable. This type of materials is not subject to rotting, the service life is increased (at least 12 years).

- In addition, progress does not stand still. New materials have appeared that are very similar to roofing material, but the technology for their manufacture is much more complicated. This is the so-called built-up "euroroofing material". Due to the complex production process, the mechanical and physical properties of the material are improved, such as strength, flexibility, aging and high temperature resistance, the permeability level is much lower than that of the traditional one. Bitumen-polymer materials on bases that are not subject to decay. Thanks to modern technologies, the number of layers can be reduced to 2-3, the service life of the coating is increased to 25 years.

For your information: currently there are self-adhesive materials. Their adhesive properties are activated by the heat of the sun. Of course, it costs more, but you don’t have to spend money on additional expenses, and it will take less time.

Roofing felt + GOST of the latest generation (3-4) materials as such do not exist.These types of roofing are produced by many manufacturers, each company has its own specifications.

The roofing material of the first two generations is marked with the letters:

- The first is "P", which means roofing material.

- This is followed by the letter designation of the type of roofing material: "K" - roofing; "P" - lining and "E" - elastic.

- The third letter designates the type of external topping. "K" - coarse-grained dressing, "M" is fine-grained, "H" - scaly mica dressing, "P" - pulverized.

For your information. If the letter “O” is present in the marking, this means that the roofing material has a one-sided dressing.

- This is followed by a dash, followed by the mark number. What does she mean? Weight of cardboard in grams per square meter of material. Naturally, the larger the number, the denser the cardboard, which means the higher the strength of the roofing material.

It is clear that everyone chooses roofing felt according to their capabilities. But no matter which one you choose, the durability of the roof will depend on the correct construction of the roofing pie and compliance with all technologies during the work.

How the roof is made

The whole process roof coverings with ruberoid is divided into two parts: preparatory and main work. The preparatory ones include straightening and cleaning the material from powder.

Roofing felt is rolled out on the roof and left in this position for at least a day. We remove the topping mechanically, moistening the surface with diesel fuel.

You should also prepare mastic and primers in advance. The first are divided into two types: hot and cold. They are used for gluing and sticking roofing material.

Hot mastic is made as follows: 8.2 kg of bitumen and 1.2 kg of filler are taken.

As a filler, you can use asbestos, peat crumbs, chopped mineral wool, sawdust and flour, finely ground chalk.

They are sifted through a sieve, the cell is not more than 3 mm. All this is poured into a container, no more than 3/4, with a closing lid and put on fire.

Heat until dense melting and the disappearance of lumps. When foam appears, floated, undissolved impurities should be removed with a net.

The process continues until the bitumen stops foaming and hissing. The result should be a homogeneous mass with a mirror surface. Yield 10 kg.

Cold mastic is prepared like this. 3 kg bitumen is taken and melted, then dehydrated.

When it cools down to a temperature of 70-90 degrees, it is poured into a container and 7 kg of solvent is added. For these purposes, a solarium or kerosene is suitable. Mix thoroughly until smooth. Yield 10 kg.

Roofing from roofing material begins with the preparation of the base of the roof. Reinforced concrete slabs are rubbed with cement; for pitched slabs, a crate is made of dry cut boards 30 mm thick.

Then, if a roofing material of the first or second generation is used, a vapor barrier is laid. It is painted and glued.

For the first option, hot or cold bituminous mastic for the roof, which is applied in a layer of 2 mm. Pasted over is made from glassine or hot mastic. The layer thickness is also 2 mm.

After that, thermal insulation is usually laid. This is done after the mastic has hardened.Thermal insulation strips are laid through one, 4-6 m wide, along the lighthouse rails. Next, it is recommended to make a cement screed.

Its thickness depends on the insulation:

- For monolithic -10 mm;

- For plate heaters -20 mm;

- For bulk -30 mm.

Next is the primer. It is produced in the first hours after laying the screed.

This is due to the fact that in this way the composition penetrates deeper into the mortar, forming a film that prevents the evaporation of water from the cement mortar and closes the pores well. For these purposes, bitumen is used.

It should be noted that the roofing material is used for roofs, the slope angle of which is not more than 25%. For a roof with a slope of more than 15%, the minimum number of layers is 2, if the slope is less, it is recommended to make 3 or more layers.

The most commonly used roofing felt is rm 350 with fine dressing. It is used for both the lower and upper layers.

The cloths are glued in an overlap. In length (if the roof has large volumes), the overlap is at least 200 mm, in width: the bottom layer is at least 70 mm, the subsequent ones are at least 100 mm.

Here it is worth paying attention to the angle of the slope of the roof. The more slope, the more overlap.

Attention! The seams of two layers cannot be in the same place. That is, each subsequent layer is rolled in a checkerboard pattern.

From above, the ridge is covered with an additional panel, the width of which must be at least 500 mm.

Roofing material should be laid from low places: valleys, cornices and gutters. Lay down the bottom layer first.

Then, after its acceptance (checked for swelling and cracks), the second layer is laid, etc.for roofing material of the first and second generation, TsNIIOMTP machines are used.

The roll is put on the axis, the tank is filled with mastic. The worker applies the mastic to the screed, levels it and then rolls it out. And so on, layer by layer.

Then the top powder is done. A layer of bituminous mastic is applied. Stone chips are poured on it and rolled with a skating rink.

When using more modern materials, gas burners are used. When laying the bottom layer, the lower part of the material is heated, after which material for the roof laid on a bituminous base.

When laying subsequent layers, not only the lower side of the roofing material and the top of the previous layer warms up. This is done to improve the adhesion of materials.

As you already understood, roofing material roofing technology depends on many factors and all of them should be taken into account during installation.

Of course, it is better to entrust this work to specialists, but if you have a desire, you can do everything yourself. The main thing is not to rush and get into the process well.

Did the article help you?