Don't know how to cut polycarbonate at home? Are you afraid to spoil the material? I will talk about cutting methods that I know, all of them are suitable for inexperienced craftsmen and provide high quality work. The main thing is to follow all the recommendations below.

Main work options

Let's figure out how to cut cellular polycarbonate at home. The most commonly used tools are:

- construction knife. You can use the usual options, but they must be very sharp;

- Scissors big size;

- Bulgarian or circular saw;

- Electric jigsaw;

- Hacksaw on wood.

Let's analyze each of the options separately.

Option 1: cutting with a construction knife

This is the simplest and most popular option for the work. You will need a construction knife with blades 25 mm wide.

You can use designs with a trapezoidal blade. This option is more durable, which means it is more convenient for them to work.

Don't forget to get spare blades as they tend to break under stress.

The workflow looks like this:

The knife is well suited for material with a thickness of 6 mm. It is very difficult to cut thicker sheets in this way, and the quality of work is not very good. Remember that a regular clerical knife with a narrow blade is not suitable, you need a 25 mm wide option.

The main advantage of this method is the low price of the tool.

Option 2: cutting with scissors

This method is used for polycarbonate with a thickness of not more than 6 mm. For work, you need tailor's scissors or metal scissors. The main thing is that the tool is sharp, otherwise the ends will be damaged.

The work instructions are simple:

Option 3: cutting with a grinder

Considering the question of how polycarbonate is cut, it is impossible not to talk about the option with a grinder. It is characterized by high speed of work and good cutting quality.

You will need a small grinder (for a disc 115-125 mm). It is small and comfortable to hold, unlike larger options that weigh a lot and therefore are not very convenient in our case.

For cutting, use cutting discs for metal with a thickness of 0.8-1.0 mm. They cut the material much more evenly, and less debris gets into the honeycombs, which is also important.

Do-it-yourself cutting is done like this:

Remember one simple rule: the protective film is always removed after cutting the polycarbonate immediately before its installation. It doesn’t matter how you cut the material, it’s worth removing the protective layer only after finishing work.

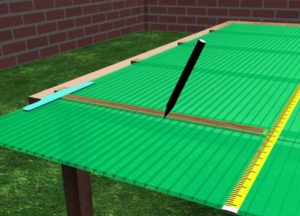

Cutting with a circular saw is carried out in the same way as with a grinder. The difference is that cutting is done using a disc with fine teeth, and the tool itself is more convenient to use due to the design that fits snugly to the surface. Some versions of the tool have a special guide and a vacuum cleaner that immediately removes all debris, which is very convenient.

Option 4: cutting with a jigsaw

An electric jigsaw is great for cutting polycarbonate of any thickness. You can quickly and accurately cut a fragment of any shape.

For work, purchase canvases with a small tooth size. This affects the quality of the cut.

The workflow in this case looks like this:

- Polycarbonate sheets are marked. If you have curved lines, then the easiest way to mark up is to attach the element on which the material is cut, and draw a markup along it. So you definitely won’t make a mistake and perfectly mark the polycarbonate;

- A polycarbonate sheet is laid out on the surface and fixed. At the same time, it is very important to position it so that there is an empty space under the cutting line, since when cutting, the blade of the jigsaw drops down by 5-7 cm. The sheet can be fixed with a load, but not very heavy so that it does not deform the material;

- The jigsaw is installed on the edge of the sheet. It is necessary to place it at the starting point of sawing, after which the tool turns on. Set the highest speed - the faster the cutting blade moves, the higher the quality of the cut;

- Sawing is done with moderate pressure. Just guide the tool along the line, turning in the right places. The most important thing is not to deviate from the line and carefully monitor the mark on the jigsaw platform, which determines the polycarbonate cutting line;

- After cutting, the ends are cleaned with a vacuum cleaner. The picture below shows that chips fall into the voids, which must be removed immediately after work.

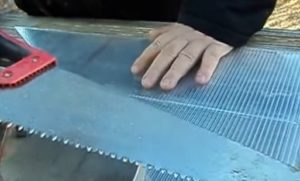

Option 5: hacksaw cutting

For work, you can use a regular hacksaw for wood. The best options are those with small teeth, they damage the ends much less and fit better into the plastic. The hacksaw must be sharp.

The workflow is simple:

Conclusion

Now you know how to cut polycarbonate at home. Choose one of the five methods and do the work in accordance with the recommendations. The video in this article will help you understand the topic even better, and if something is not clear to you, ask in the comments.

Did the article help you?