Waterproofing film is the most popular roof waterproofing material today. There are many varieties on the market, which makes it difficult for beginners to choose. To help in this matter, I will talk about the three best, in my opinion, types of film and their features.

Features of choice

Let's figure out how to choose this material correctly. When buying, you need to pay attention to the following characteristics:

- Waterproof;

- Strength;

- Heat resistance (resistance to low and high temperatures);

- Elasticity;

- Durability;

- Value for money.

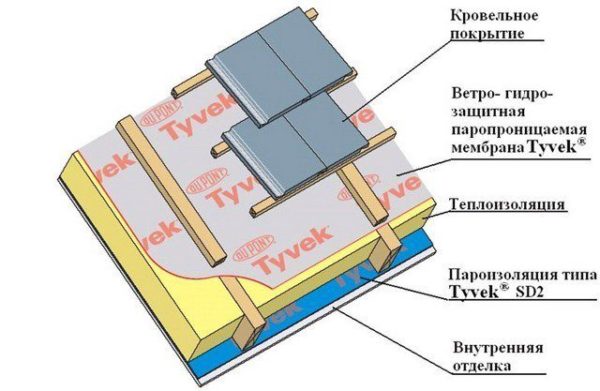

For warm roofs, it is desirable that the film has such a quality as vapor permeability. This allows accumulated moisture to escape.

Good waterproofing must meet all of the above requirements. In this case, the waterproofing of the roof will effectively cope with the task for many years.

Types of films

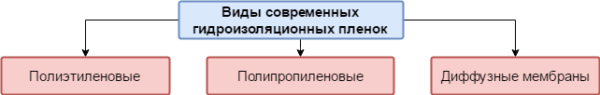

Currently, the following types of films are very popular:

Let's take a closer look at each of these film types.

Option 1: polyethylene

Polyethylene waterproofing film for roofing is the most budget option to date. They are commercially available in three types:

- single layer. It has low strength, so it is better to refuse its use on the roof;

- reinforced. Consists of three layers. The middle layer is fiberglass mesh, which makes the film more tear-resistant;

- perforated. Has microperforation that does it vapor-permeable.

I must say that perforated polyethylene waterproofing films are not widely used, as they have a number of disadvantages - they are easily damaged, in dry weather the holes are clogged, which reduces vapor permeability.

Advantages:

- Low cost. This coating is the cheapest of all rolled waterproofing roofing materials;

- Efficiency. The film is completely waterproof. The only thing is that for this, when installing with your own hands, it is necessary to strictly observe the technology of its laying;

- Heat resistance. The material is not afraid of frost or the scorching sun;

- Strength. Reinforced film is not afraid of large wind loads;

- Durability. The service life depends on the quality of the material. A good plastic film can last more than 30 years.

However, there were cases when, after a few years, the film began to peel off, as a result of which only the reinforcing mesh remained.

In order for the film to reliably protect the under-roof space from moisture, when laying it is necessary to ensure that the upper strip overlaps the lower one by 200-250 mm. In addition, it is desirable to glue the joints with double-sided adhesive tape, especially for roofs with a small slope angle.

Flaws:

- Lots of low quality products. Therefore, it is advisable to purchase the film from well-known manufacturers that provide a guarantee for the material;

- Possibility of damage. Sharp surfaces easily damage the polyethylene film. Therefore, during installation, it is necessary to exclude the possibility of its contact with the tips of nails, self-tapping screws or other sharp parts;

- Zero vapor permeability. As a result, polyethylene films are not recommended for insulated roofs. At the same time, they can be used as a vapor barrier, i.e. mounted on the inside of the heater.

As a rule, polyethylene films are used for waterproofing the under-roof space of various outbuildings, garden and country houses. In addition, as I said above, they are often used as a vapor barrier for insulated roofs.

Characteristics:

| Options | Meaning |

| UV resistance | 3 months |

| Tensile strength | 630 N/5 cm |

| moisture resistance | 0.1 m water column |

Price. The price of a roll of reinforced film starts from 1500-1600 rubles.

Option 2: polypropylene

Polypropylene films are characterized by higher strength and durability. Like polyethylene counterparts, they have a reinforcing layer. In addition, their sides usually have a different surface:

- Upper side (facing the roofing material). It has a smooth surface, which allows drops to roll down unhindered;

- Lower. It has a rough surface formed by cellulose-viscose fibers. They trap moisture on the surface, allowing it to evaporate.

Advantages:

- Strength. Polypropylene waterproof film has not only high tear strength, but also puncture resistance;

- Efficiency. Provides reliable protection of the under-roof space from moisture.

- Heat resistance. This material can be used even in the most severe climate;

- Durability. Such films serve more than 20 years.

Flaws:

- Zero vapor permeability. Like the polyethylene counterpart, this coating should not be used with an insulated roof;

- higher cost. It costs more than a polyethylene counterpart.

The scope of polyurethane films is the same as that of polyethylene.

Characteristics:

| Options | Meaning |

| UV resistance | 6 months |

| Tensile strength | 640 N/5 cm |

| moisture resistance | 0.3 m water column |

Price. The average price is 10-15 rubles per square meter.

Option 3: diffuse membranes

Diffuse waterproofing membranes are usually made from polypropylene film. However, they can be separated into a separate material. Their main feature is the ability to pass steam in one direction.

The waterproofing membrane for the roof works according to this principle:

- Collects moisture from the inside. Steam settles on the villi of the membrane;

- Brings moisture out. The moisture that has settled on the villi seeps through the micro-holes;

- Removes moisture. Thanks to the smooth upper surface of the membrane, drops of moisture flow down unhindered.

Thanks to this quality, vapor-permeable waterproofing materials for the roof have recently been most popular.

Keep in mind that, depending on the vapor conductivity index, diffuse membranes are divided into three types:

- Small diffusion. The vapor transmission capacity of these waterproofing materials is no more than 300 mg per 1 m2 in 24 hours;

- medium diffusion. Able to skip up to 1000 mg of water per square meter per day;

- Super diffuse. Able to pass more than 1000 mg of water per day per 1 m2.

On roofs that will be covered with metal materials (corrugated board or, for example, metal tiles), anti-condensation membranes should be used. They are able to absorb a large amount of moisture (condensate), and then give it away when favorable conditions occur.

Advantages:

- Durability. Diffuse films serve at least 30 years. The most expensive reinforced models can last up to 100 years;

- Reliability. The film reliably retains moisture from the inside. True, the installation instructions for some of them require an angle of inclination of at least 35 degrees. Therefore, before buying, carefully study the description for the material;

- Strength. The membranes are resistant to any mechanical stress;

- Heat resistance. They withstand great frosts and warming up in the sun.

Flaws. A diffuse membrane is, one might say, the best waterproofing for a roof. She has no obvious flaws. The only thing that can be distinguished is a higher cost compared to other films.

In addition, as I said above, some models of membranes do not “hold” water well, therefore they have a limit on the angle of the roof.

In general, diffuse membranes are an excellent choice for waterproofing the under-roof space of residential buildings.

Characteristics. The parameters of diffuse membranes may vary, depending on the model and manufacturer, but in general they are approximately the same.Therefore, as an example, I will give the characteristics of the Yutafol D 96 membrane, popular on the domestic market:

| Options | Meaning |

| UV resistance | 3-4 months |

| Tensile strength | 600 N/5 cm |

| Vapor permeability | 18 g |

Price:

| Brand | Cost per roll, rubles |

| Izospan AS (1.6x43 m) | 3400 |

| Ondutis (1.5x50 m) | 2900 |

| Docke D-folie A150 (1.5x50 m) | 5400 |

| Yutawek (1.5x50 m) | 3780 |

| DuPont Tyvek (1.5x50 m) | 6000 |

That, in fact, is all the waterproofing films that I wanted to tell you about in this article.

Conclusion

Now you know what characteristics and properties a waterproofing film can have, and what types of it exist. Watch the video in this article for more. If any nuances caused you questions, write comments, and I will be happy to answer you.

Did the article help you?