You need roofing mastic, but how to choose the right one so that the coating is effective and durable? I will talk about the most common types of mastic and their features, which will help beginners answer the question.

General information

Roofing mastics are a viscous liquid, which hardens after application, forming an elastic and at the same time sufficiently strong surface. Moreover, the coating has high waterproofing properties.

As a rule, roofing mastics are made on the basis of bitumen. Sometimes, to improve their properties, bitumen is modified with various polymers. In addition, fillers are added to the composition of the material, which can be used as:

- Mineral wool;

- Limestone or quartz powders;

- Combined ash, etc..

Non-reinforced mastic can be used to seal the joints of rolled roofing

There are also mastics that do not contain reinforcing additives, which allows them to be applied in a thin layer. These compounds are usually used for gluing and sealing the joints of rolled materials, as well as for gluing them to the roof base.

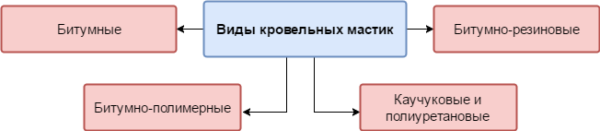

Types of mastic

The main characteristics and performance of the material depend on the type of binder. According to this parameter, coatings are divided into the following types:

Next, we will consider all these options for mastics, so that you yourself can decide for yourself which one to choose.

Bituminous

Bituminous mastics are the most popular due to their low cost and good performance.

Bituminous mastic has the lowest cost

Advantages:

- Good adhesion. This allows you to apply the composition on various surfaces. At the same time, the coating does not peel off during the entire period of operation;

- Durability. Bituminous roofing mastic can last up to 25 years, and sometimes more;

- Ease of application. Like most similar coatings, bitumen-based formulations are easy to apply with your own hands using a roller or spatula;

- UV resistant. This allows the coating to be used as an independent base layer.

Flaws:

- Sun resistance. The material is destroyed under the influence of ultraviolet rays. In addition, when heated in the sun, the bitumen softens and can drain, so mastic can only be applied on roofs with an angle of inclination of no more than 30 degrees;

- The need for additional coverage. For the above reasons, this material needs additional coating. Most often, euroroofing material is glued on top;

- Long drying process. In dry thermal weather, the composition dries up within a day. This must be taken into account before application, as the roof is covered with bituminous mastic in several layers.

Varieties:

- Hot application (hot). It has a solid consistency.

Before applying hot mastic, it is heated until a liquid consistency is obtained. Therefore, this mastic was nicknamed "hot" by the people.

Roofing hot mastic is inconvenient to use, but it costs less. In addition, it dries faster than "cold";

- Cold application. It softens due to the use of a solvent in the composition.

There are two types of cold mastics - one-component and two-component. The former are sold ready-made, while the latter must be mixed with a solvent before use.

I must say that mastic roofs treated with a two-component material usually turn out to be more durable and reliable.

Separately, it should be said about water-based formulations, which are a water-dispersion mixture. Their advantages include not only ease of use, but also environmental friendliness, as well as a faster drying rate.

If mastic is used for soft roofing with a slope angle of more than 6 degrees, it is recommended to reinforce it with fiberglass or other material.

Price:

| Brand | Price in rubles |

| AquaMast 1 kg | 45 |

| Decken 1 kg | 50 |

| BiEM (water dispersion) 20 kg | 670 |

| TechnoNIKOL 1 kg | 60 |

| MBI 15 kg | 245 |

Bitumen-polymer

Bitumen-polymer mastic contains acrylic, latex or other polymers. Thanks to this, it has higher performance.

Advantages:

- Fast drying. The drying speed of this roofing is several times higher than the drying speed of a conventional bituminous analogue;

- Heat resistance. The coating can withstand temperatures up to 70 degrees. This allows you to apply it on roofs with a slope angle of more than 30 degrees;

- Good adhesion. Can be applied to any roof covering. This allows you to use this material for the repair of roofs of almost any type.

Flaws. The disadvantages of the material include only a relatively high cost.

Price:

| Brand | Price |

| Rastro 1 kg | 130 |

| Hydropan 1 kg | 190 |

| HYDRIZ-K 10 kg | 840 |

| Weber tec 8 kg | 2150 |

Instructions for applying mastic, regardless of the type of the latter, require careful preparation of the roof.Namely, it must be cleaned of dust and dirt, as well as crumbling and flaking surfaces.

Bituminous rubber

Bitumen-rubber or rubber-bitumen mastic is a conventional bituminous composition, to which rubber crumb is added. As a rule, waste rubber is used for these purposes, due to which the addition of crumbs practically does not affect the cost of the material.

As a result of adding rubber, the following qualities of the material are improved:

- Melting temperature. Practically does not melt in the sun;

- Waterproof. The roof surface becomes much more moisture resistant;

- Plasticity and elasticity. Thanks to this quality, the coating does not crack and lasts longer.

Otherwise, the properties of this material are the same as those of a conventional bituminous counterpart with its advantages and disadvantages.

The scope is also the same. The material is used for the following purposes:

- Installation of mastic roofs using roofing material, euroroofing material or other rolled coatings;

- Bonding joints of rolled materials.

Price:

| Brand | Cost in rubles |

| TechnoNIKOL 20 kg | 1760 |

| Kraskoff 20 kg | 820 |

| Coloring 1.8 kg | 140 |

rubber and polyurethane

Rubber and polyurethane mastics are also made on the basis of bitumen. Their main feature is high elasticity, which is why they are also called "liquid rubber".

This mastic is applied in one of the following ways:

- Painting method. In this case, the composition of a creamy consistency is applied with a roller, brush or spatula;

- By pouring way. The essence of this method is to pour "liquid rubber" onto the surface of the roof and then level it. Therefore, this method can only be used for flat roofs.

- Sprayed. To apply mastic in this way, special equipment is required. I must say that this method allows you to get the most durable and durable coating.

Advantages:

- Elasticity. It can stretch by 300-400 percent, and at the same time maintain integrity;

- Versatility. Can be used for both flat and pitched roofs. With the help of "liquid rubber" it is possible to repair roofs covered with almost any roofing materials;

- Atmospheric resistance. The coating is absolutely not afraid of moisture, as well as low and high temperatures. In addition, the material is resistant to sunlight.

Therefore, it can be used for mastic roofing as an independent coating; - Durability. Mastic roofing covered with this material can last up to 50 years;

Flaws. The downside of "liquid rubber" is only a high cost.

Price:

| Brand | The cost of 1 kg in rubles |

| Slav | 184 |

| LKM CCCP | 210 |

| AKTERM | 250 |

| Fargotek | 349 |

Conclusion

Now you know what types of roofing mastic are, and you can independently choose the best option, depending on the situation.I recommend watching the video in this article. If some points are not clear to you - write comments, and I will definitely answer you.

Did the article help you?