The roof ridge is a horizontal rib that is located at the junction of the slopes at the highest point of the roof. The correct arrangement of this node largely determines the reliability and efficiency of the functioning of the roof, therefore, before starting work, it is worth studying the design of the ridge in as much detail as possible.

The design of the upper roof node

Functions and design

Outwardly, the ridge on the roof looks quite simple: for the layman it is just an overlay, the edges of which go to the roof slopes. But in practice, the design of the skate is designed to solve a number of problems:

- Reinforcing rib. The ridge beam at the top connects the rafters into a single system, providing support to the rafter legs.

- Moisture protection. An overlay strip (a roofing corner or a special profiled part is used) closes the junction of the slopes. In addition, additional waterproofing is laid under the lining, which also blocks the penetration of moisture under the roof.

- Ventilation. With the correct arrangement of the ridge, it is this node that provides free air circulation in the gap between the waterproofing and the roof. The edges of the lining on the upper rib partially cover the gap, protecting it from dust, fallen leaves and other debris.

For more effective protection, a special material (figarol and analogues) is used. The edges of the roll are fixed on the surface of the roofing, and the perforated inserts are responsible for ventilation. The price of materials is quite high, but in this way we will ensure both air exchange and high-quality waterproofing.

The ridge of the roof can be arranged according to different schemes. But at the same time, the principle of its functioning remains unchanged, so that the main elements of different designs will be similar:

How to calculate height?

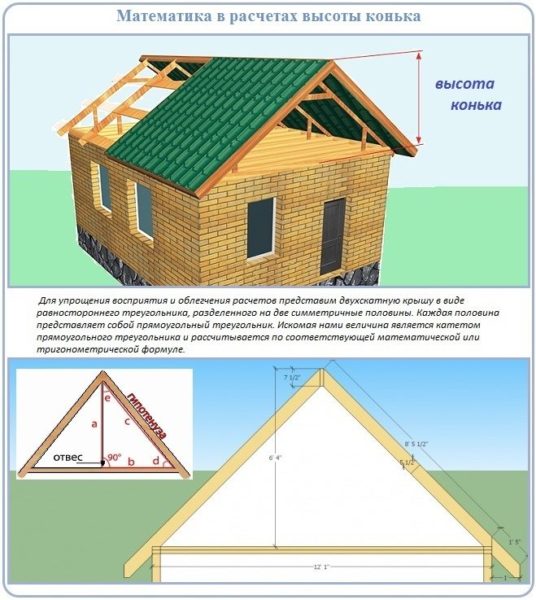

The calculation of the height of the roof ridge is carried out at the design stage. It is very important for the simplest reason: this is the highest point of the roof, and therefore its height directly determines both the dimensions and the material consumption.

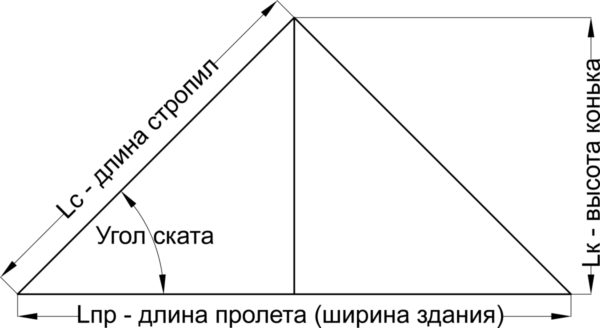

It is best to perform the calculation according to the formula:

a = tg α * b, Where:

- a - the desired height from the ceiling to the ridge;

- tg - tangent (mathematical function);

- α - the angle of the roof slope laid down in the project;

- b - half the width of the run (distance between the walls).

If you do not want to mess with the calculations, you can use the coefficient table:

| Slope, degrees | 15 | 20 | 25 | 30 | 35 | 40 | 45 | 50 | 60 |

| Coefficient | 0,26 | 0,36 | 0,47 | 0,59 | 0,79 | 0,86 | 1 | 1,22 | 1,78 |

When calculating the width of the house is multiplied by the coefficient for the required slope angle. . So, if we have a structure 6 m wide with a roof whose slopes are at an angle of 35 °, then the highest point will be at a height 6 * 0.79 = 4.74 m.

This is how the distance from the ceiling to the top point of the run or the junction of the rafters is calculated. Keep in mind that ridge elements can be mounted on brackets, so that the actual rise will be about 100–200 mm higher.

The steeper the slope, the higher the ridge will be from the ceiling

(not a valid myme-type of the file)

Mounting technology

Preparation: frame and waterproofing

Now let's figure out how to make a skate on the roof with your own hands. You need to start with the installation of the frame and waterproofing of the ridge assembly:

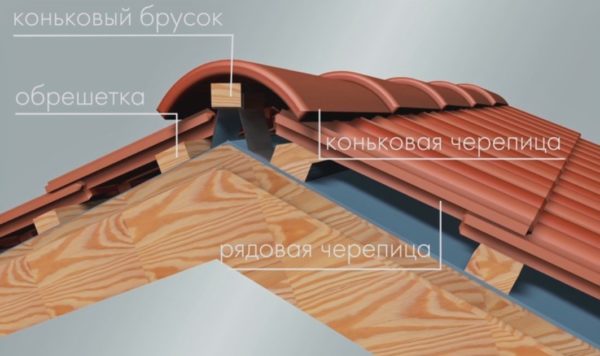

Method 1. For ceramic tiles

Ceramic tile is a rather difficult material to install. Therefore, the instruction for the device of the ridge knot involves a large amount of additional work:

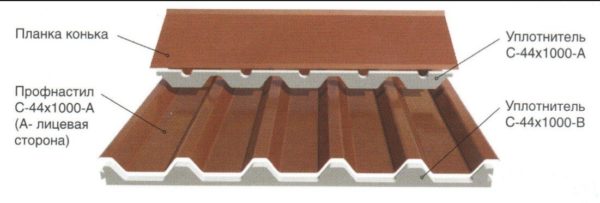

Method 2. For corrugated board and metal tiles

It is much easier to figure out how to fix the lining on the roof of corrugated board or metal tiles:

Conclusion

Having figured out what a roof ridge is and what functions it should perform, you can easily choose the optimal design for any type of truss system. The video in this article, as well as the advice of experienced craftsmen, will help you in the practical implementation of the project. You can get them by asking a question in the comments.

Did the article help you?