Greetings, comrades! We have to figure out how the mansard roof truss system works. I will introduce you to its main elements, their functions and share my own experience in building an attic floor. But first, a few definitions to help us avoid confusion.

Definitions

Attic is traditionally called a very specific type of roof - broken, that is, with two slopes with a variable slope. However, the traditional definition is incomplete.In fact, this can be called any roof that allows you to place an attic under it - a living space limited by roof slopes.

The semi-mansard roof differs from the mansard one in that it rests on the main side walls with a height of at least one and a half meters. The semi-attic uses space more advantageously: it does not have areas with low ceilings that are unsuitable for use as living space.

Here are the main types of mansard roofs:

Elements

In order not to make the reader confused in terms, I will give a few more definitions. Here are the main elements of the truss system:

Scheme

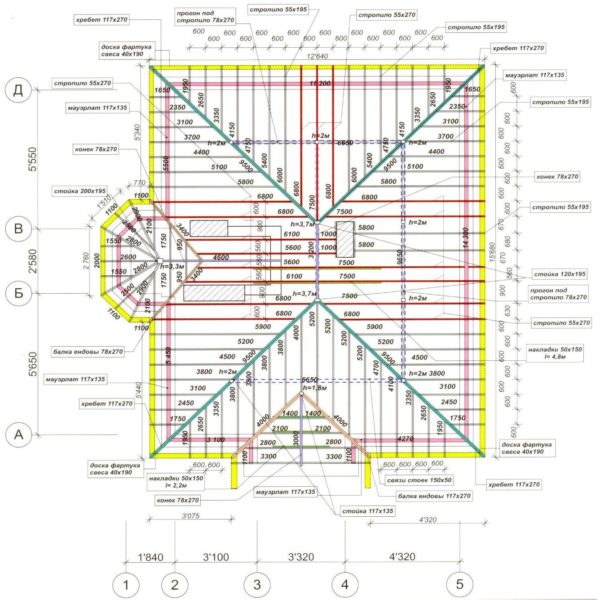

Now it's the turn of drawings and diagrams.

Gable roof

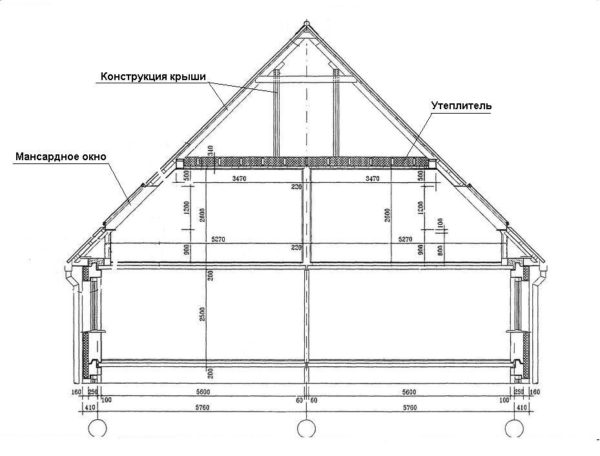

The large span of the roof forces the use of a central post, on which the layered rafters rest. The side racks give the slopes additional rigidity and serve as a frame for the attic walls.

Resistance to snow load is provided by a pair of crossbars: the first serves as the basis for a horizontal insulated ceiling, the second is hidden in a cold attic.

Another, simpler gable roof truss system with an attic. The center console is missing. The shortened crossbar makes the ceiling broken: the horizontal central part is adjacent to the inclined sections.

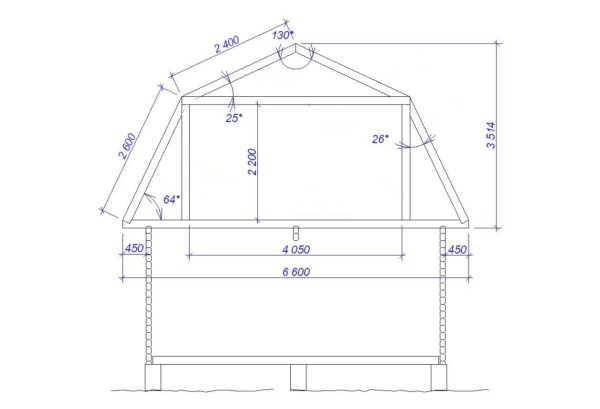

broken roof

At a broken mansard roof, the posts are always installed exactly under the break. The crossbar that tightens the fractures with each other provides maximum rigidity of the structure.Alas, such a scheme has a serious drawback: the ceiling remains relatively low even in the center of the attic, although the height of the ridge allows you to raise it a few more tens of centimeters.

A shortened crossbar connecting the upper rafters approximately in the middle of their length allows you to raise the ceiling with little or no damage to the strength of the truss system.

hip roof

Here, rigidity is provided by slanted (corner) rafters with uprights in the middle of their length. Racks are interconnected by horizontal links. Outdoor rafters rest on slanted rafters and form a solid foundation for the roof.

A feature of the hip roof is the absence of vertical gables, so natural light is provided by skylights cut into the roof.

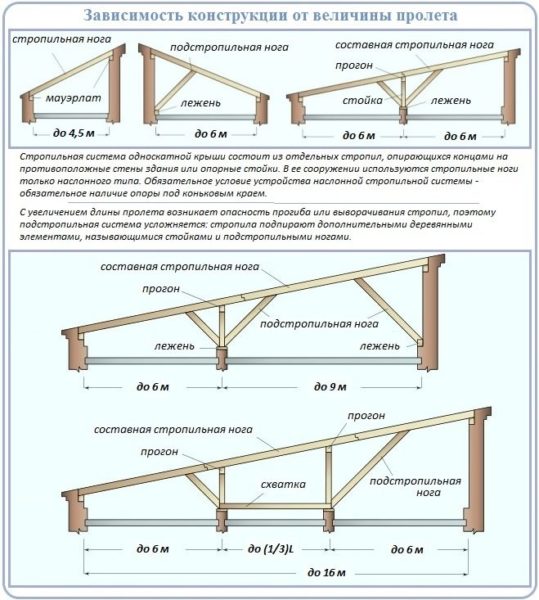

shed roof

For a single slope, the problem of ensuring resistance to snow load comes first, therefore, when spanning more than 4.5 meters, the rafters need additional supports.

The diagram shows the options for their installation:

- With a span of up to 6 meters, sufficient rigidity will be ensured by the installation of an oblique rafter leg;

- The central post with a pair of rafter legs allows you to increase the span up to 12 meters;

- Two intermediate racks with oblique legs and a bunch between them make it possible to make a 16-meter span.

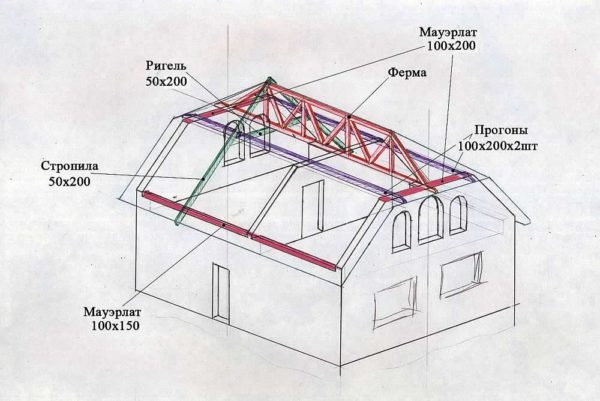

Half hip roof

The height of the gables allows you to shift the main load on them. A prefabricated truss rests on the gables, which serves as a support for the side rafters.For greater rigidity, the rafter legs are interconnected by crossbars and longitudinal runs.

Knots

How to do the installation of the truss system connections with your own hands? At your service - a description of how to install the main components.

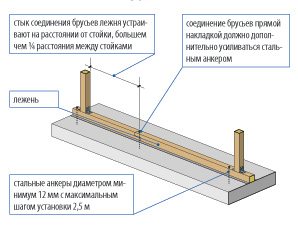

Mauerlat fastening to the walls

Mauerlat is made of timber with a section of 100x100 - 150x150 mm. The beam must be treated with an antiseptic without fail. The walls under it are waterproofed to prevent capillary suction of water by wood; usually the role of waterproofing is performed by a couple of layers of roofing material.

For fastening the Mauerlat, anchor studs are usually used, installed when pouring the armored belt along the perimeter of the wall. Under them, holes are drilled in the beam, and after laying the beam is attracted to the armored belt with nuts with wide washers.

Fastening rafters to Mauerlat

For maximum rigidity of the connection of the rafter legs with the Mauerlat, a cut is usually made in them by a third of the width of the rafter. For fastening can be used:

- Steel staples. They are driven into both beams from two sides;

- Galvanized corners. They are attached to both beams with several self-tapping screws with a length of at least 2/3 of the rafter thickness.

Galvanized corners and linings are used to connect the rafter legs to each other, with racks, with horizontal girders and floor beams. The pads can be replaced with thick (not less than 15 mm) plywood, pro-oiled to protect against dampness.

Fastening the crossbar to the rafters

The connection of the crossbar with the rafters of a gable or sloping roof experiences the most severe loads in winter, when there is snow on the roof. A simple instruction will help to make it as strong as possible: the crossbar is connected to the rafter overlaid and attached to it with a pair of bolts with nuts and wide caps through pre-drilled holes.

materials

The best material for a truss system is cedar, which is lightweight, durable and resistant to rot. However, in practice, cheaper ones are used much more often: spruce, fir and pine. All loaded elements of the truss system (rafter legs, crossbars and racks) must have no wood defects that affect strength:

- Large falling knots;

- Oblique (deviation of the direction of the fibers from the longitudinal axis of the timber);

- Oblique cracks;

- Rot.

A typical cross-section of beds and racks is 100x50 mm. The cross section of the rafters is determined by their length and the step between the rafter legs: the larger it is, the greater the load falls on a separate beam. You can choose the optimal cross-section of the rafters according to the table in the line below.

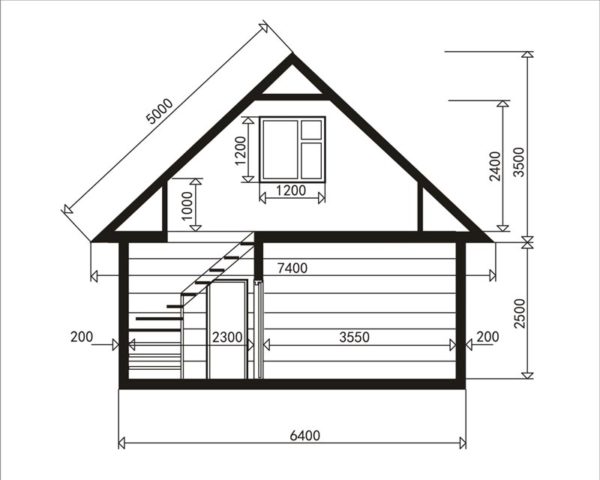

My experience

During the construction of the attic, I chose a sloping roof. For the installation of the truss system, a pine beam with a section of 50x100 mm was purchased. The step between the rafter legs is 90 cm, the maximum span is 3 meters. The angle of inclination of the roof is 30 degrees for the upper slopes and 60 for the lower ones.

The crate for roofing material (profiled sheet) is assembled from unedged boards with a thickness of 25 mm.It is from unedged - simply because its price is lower, and the appearance when laying under the roof does not matter. Lathing pitch - 25 cm.

The crossbar pulls together the upper rafters approximately in the middle of their length. The suspended ceiling made of GKL is assembled on ceiling profiles fixed to the rafter legs and crossbars with direct suspensions.

The design of the truss system has proved its strength: for four seasons it successfully resists the strongest winds typical of Sevastopol winters.

Conclusion

I hope that I was able to answer all the questions that the reader has accumulated. As always, the attached video will offer additional materials to your attention. I look forward to your comments and additions. Good luck, comrades!

Did the article help you?