This article will consider metal slate, made of galvanized iron and often called corrugated board, its main pros and cons and features of roofing with this material.

This article will consider metal slate, made of galvanized iron and often called corrugated board, its main pros and cons and features of roofing with this material.

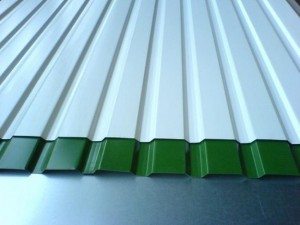

Slate metal is covered with a special polymeric protective coating and can be produced with different types of waves.

Until recently, it was believed that this type of slate is suitable only for covering fairly large industrial buildings, but the improvement in production technology, as a result of which this material received a protective polymer coating, made it possible to use it also in the construction of residential buildings and relatively small household and household buildings.

Metal slate is produced by cold stamping of galvanized sheet steel, coated with a primer and a special composition for protection against corrosion.

From the front side this roofing material covered with a layer of polymer coating, which gives the material the following properties:

- Durable and reliable protection against corrosion;

- Increased color stability;

- Attractive aesthetic appearance of slate.

On the underside, the iron slate is covered with a thin layer of a special varnish that provides additional protection. To obtain profiles of various shapes and configurations in industrial conditions, transverse stamping of sheets is performed.

Iron slate is of high quality at a fairly low price, which allowed it to be widely used in industrial, commercial and individual construction.

This material is used when performing the following works:

- Installation of roof structures;

- Construction of fences;

- Erection of temporary buildings and structures;

- Equipment of enclosing structures in the process of construction of prefabricated buildings, etc.

The main advantages and disadvantages of the material

The main positive characteristics that a metal slate possesses include the following:

- Long service life, and service life guaranteed by manufacturers is 30 years or more;

- Low weight of the material, which is about 4-5 kg per square meter;

- Ease of installation. Regardless of the type of construction, it can be done by one person without special skills and knowledge, using ordinary screws, nails and anchors;

- Immunity to the influence of temperature extremes, which allows the installation of the material regardless of the time of year;

- Aesthetic appearance of the material;

- Environmental Safety;

- Saving money: despite the fact that steel slate is cheaper than ondulin, it has a longer service life and does not require the installation of additional reinforcing roof structures;

- The smooth surface of the metal slate does not create obstacles for the removal of water and snow;

- High fire safety and heat resistance;

- Suitability for repair.

The disadvantages of the material include:

- Insufficiently good sound insulation;

- Susceptibility to corrosion without the use of protective agents;

- The manufacture of complex structures requires an increased consumption of building materials.

Metal slate roof installation

Consider the procedure installation of metal slate, or corrugated board, on the roof. . This material is made in the form of metal profiled sheets of galvanized steel or aluminum.

The rectangular or wavy profile of the sheets gives the metal slate additional rigidity.

When covering the roof with metal slate, care should be taken when moving along the laid sheets, since this material is not designed for such significant loads and may wrinkle.

Installation of metal slate consists of several stages:

- Since different manufacturers make sheets of metal slate in different sizes, before starting roofing work, you should carefully calculate how many sheets will be needed to cover one slope.To ensure the correct measurements of the slope, it is necessary to check the squareness of the roof, as well as measure the dimensions of the battens;

Useful: the greatest convenience of roofing installation is achieved when the length of the sheet is equal to the length of the slope.

- roof lathing can be made from wooden blocks or from ordinary boards. The thickness of the boards or the section of the bars is selected in accordance with the thickness of the slate sheets, and also taking into account what kind of fasteners will be used.

Important: it must be remembered that the thickness of the first board, located along the eaves, must be greater than the thickness of all other boards.

- Along the perimeter of elements such as pipes, hatches and ventilation, the crate must be reinforced by installing additional boards or beams. Next, a waterproofing material is laid on it, which prevents the occurrence of condensate.

- Installation of sheets is carried out in such a way that they protrude slightly above the eaves. The first sheet is fastened with a screw in the center, which allows you to freely turn the sheet to the left or right, and the following sheets are overlapped, their fastening is carried out at the corners of the sheets.

- After mounting several sheets, it is necessary to align them relative to the cornice with a cord, after which you can proceed to attach the metal slate to the crate. In this case, the first sheets of the first and second rows are first fastened together, and then these sheets are attached directly to the crate.

- In the case when an odd number of profiled sheets of metal slate is required when covering a gable roof, the last sheet of material should be cut into two equal parts.

The reliability of fastening sheets of metal slate is ensured by the use of special self-tapping screws made specifically for this purpose. The size of such screws is 2.8x4.8 mm; during production, they are supplied with a special rubber washer-seal.

The screws are screwed in along the internal waves of the material, and the screws must be located strictly perpendicular to the metal slate.

Useful: you can speed up the process of installing a metal slate roof using tools such as an electric drill running at low speed or a screwdriver.

When screwing self-tapping screws into the outer waves of metal slate, special care should be taken to avoid damage to both a single wave and the entire sheet of material.

This type of fastening should be used only if the material is laid along the seams - this avoids the vibration of the sheets under the influence of strong gusts of wind.

The consumption of self-tapping screws per square meter of metal slate coating is inversely related to how long the sheets of material are: shorter sheets require more self-tapping screws for fastening. In practice, 8-12 self-tapping screws are usually used per sheet of material.

Important: it should be remembered that, unlike ordinary slate, metal is a very slippery material for roofing, therefore, in order to prevent the melting snow cover from falling, snow retainers should be equipped on the roof.

That's all I wanted to talk about metal slate (profiling). The correct selection of material and its competent installation will make it possible to cover the roof with metal slate quite simply and at a low price, ensuring the durability and reliability of the roofing.

Did the article help you?