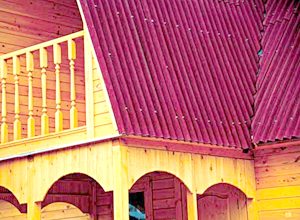

Many may describe slate as a roofing material with many disadvantages: heavy weight, fragility, gray appearance. Modern technologies for the manufacture of slate have relieved the material of these shortcomings. Today, this product is distinguished by an interesting design, lightness, diversity: natural, soft slate. This article touches on the description of the latter option.

Many may describe slate as a roofing material with many disadvantages: heavy weight, fragility, gray appearance. Modern technologies for the manufacture of slate have relieved the material of these shortcomings. Today, this product is distinguished by an interesting design, lightness, diversity: natural, soft slate. This article touches on the description of the latter option.

The relevance of roofing

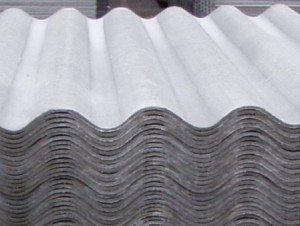

The most economical and common material is asbestos slate, which is based on asbestos, cement and water. This coating has many positive properties:

- stability at low temperatures;

- fire resistance;

- long service life;

- thermal insulation.

Along with the advantages, asbestos roofing has significant disadvantages:

- large mass;

- low strength;

- the impact of asbestos on human health.

Due to the presence of a wide range of shortcomings, this material is losing its relevance, and it is being replaced by natural slate (slate), which has a variety of shades.

Natural roofing has the following characteristics:

- rich color range, which allows you to expand the possibilities of architectural design;

- material durability;

- high frost resistance, which is important when using the coating in regions with an unstable climate;

- low hygroscopicity causes resistance to moisture even during heavy rains;

- high sound insulation and heat capacity;

- material strength;

- exclusion from the composition of harmful impurities.

As you know, natural coatings are much more expensive than artificial roofing materials.

If a consumer chooses a roof with an optimal ratio of quality and price, then soft slate remains more relevant in this matter - a type of artificial roofing.

Characteristics of soft slate

In the manufacture of this coating for slate roof mineral fiber and impregnation in the form of bitumen are used. After applying bitumen to the base, the technical properties of the material are significantly improved.

In addition, the material is subjected to decorative transformations - staining in any color.

In production, in addition to the bituminous layer, components of various resins and additives are used, which improves the strength and properties of the coating.

Usually this roofing material is used on roofs with a simple architectural form.But practice has shown that it performs its functions on complex roofs. Due to this, it is increasingly being used on the roofs of one- and multi-storey buildings.

Attention. Compared to ordinary slate, soft slate is made from safe products, does not include asbestos in its composition, therefore it is absolutely harmless to humans.

Advantages of soft slate

The popularity of this roofing material is due to a number of advantageous indicators:

- Environmental friendliness. As we have already said, unlike asbestos coating, this material is not hazardous to health;

- Moisture resistance. Soft slate has a low rate of water absorption;

- biological stability. The roof of soft slate is resistant to bacteria, fungi, is not subject to decay;

- Durability. If the installation rules are followed, the service life of the slate exceeds 50 years. The manufacturer's warranty for this roofing is 15 years;

- Ease of transportation. Light weight allows you to store and transport the material with ease;

- Profitability. . Simplicity and ease of laying is also due to light weight, no reinforcement of the roof structure is required. In addition, the material is completed with additional parts;

- Good noise absorption performance.

This material is often called ondulin, due to the similarity of properties and installation rules. Although ondulin is based not on mineral, but on cellulose fibers, which are also covered with bitumen and a decorative layer.

Installation instructions

The installation process of soft slate includes several stages:

- At the preparation stage, it is necessary to calculate the amount of material, taking into account the fact that the sheets are overlapped. During the construction and arrangement of the roof in difficult climatic conditions, the amount of overlap increases;

- In the event that an old roof is being repaired, it is necessary to check the condition of its surface. It is possible to lay a new coating on the old one. But for reliability, the coating spoiled by time, fasteners are removed, the rafters and the crate are replaced if necessary;

- In order to provide the roof with additional protection, roofing felt is laid under slate or waterproofing;

- The laying of sheets starts from the bottom corner to ensure the structure is symmetrical. A wave of one sheet covers another. When laying the second row, new sheets overlap the previous ones by about 10 cm, this prevents the roof from leaking;

- Sheets are fastened with special nails for slate. To avoid the appearance of cracks, the fastener is placed in a wave;

- At the end of the laying of all sheets, the ridge is equipped.

Attention. Reliability of fastening depends on the length of the fastener. It is necessary to observe that the nail enters the boards of the crate.

Mounting technology

The technology for laying soft slate is described in some detail in the instructions that come with the materials. In this article, we will focus on more important points that you need to know to ensure high-quality styling:

- The main positions that you need to pay attention to are the pitch of the boards of the crate and the size of the overlap of the sheets.

When laying slate on roofs with different slopes, the type of crate and overlap differ:

-

- on a roof with a slope of 10 degrees, a continuous crate of OSB or plywood is mounted, the lateral overlap is two waves, the transverse one is 30 cm;

- on a slope with a slope of 15 degrees, a crate is allowed with a pitch of 450 mm or less, while the overlap of the wave along the side is performed in one wave, and at the ends of the sheet - 20 cm;

- when the slope exceeds more than 15 degrees, the pitch of the crate is allowed at 610 mm, overlapping in one wave along the side and 17 cm at the ends of the slate sheet.

- When arranging the crate, it is necessary to adhere to the parallelism of nailing the bars.

- To give the sheet the required size, you can use reciprocating or circular electric saws.

- Laying sheets can be carried out independently even by one person, since the material has sufficient lightness.

- As we have already said, laying starts from the corner of the slope, from the leeward side. The second row is laid from half a sheet. This leads to the fact that at the corner an overlap is formed not in four, but in three sheets, which facilitates installation.

- Fastening is carried out by special slate nails in each wave at the ends of the sheet and along the edges of the side overlaps.

Attention. The nail must enter the top of the corrugation strictly perpendicular so that the sealing washer is in contact with the coating. Hammering is performed smoothly without excessive or insufficient deepening. With a slight pressure on the wave, there should be no gap between the seal and the slate sheet.

Soft slate is a durable and lightweight roofing material. Its installation is the best choice for reliable roofing of any building structure for a long time. At the same time, the purpose, type of object, climate do not matter much.

Did the article help you?