Slate is one of the most common types of roofing material today. Slate roofs are almost ubiquitous, and the main reason for this (besides the quite decent performance that it has) is their low cost. Indeed, few roofing materials can compete with slate in terms of price-quality ratio.

In addition, the slate roof is quite simple to arrange, and you can learn the technique of slate work yourself.

That is why, if you yourself decide to do the arrangement of the roof of your house - we recommend that you consider slate as one of the options.

Varieties of slate roofing

In fact, slate today means a whole group of roofing materials.

So if you decide to cover the roof with slate, then you can be offered:

- Natural slate is a layered natural material previously used for roofing. Today, this kind of slate is almost completely replaced by artificial roofing materials.

- Asbestos cement slate - the most common type of slate, which is a smooth or wavy slab from a mixture of asbestos fiber and Portland cement.

- Asbestos-free slate is a variant of slate in which various natural or synthetic materials (from jute fiber to polyacrylic) are used as a filler instead of asbestos fiber. Asbestos-free slate roofing is considered more environmentally friendly, but its main advantage is in a much smaller mass.

- Euroslate - is a slab of bituminous material, made with a characteristic wavy profile.

- Composite slate, or keramoplast, is a type of roofing material made from composite materials (Footnote 1).

As you can see, there are plenty to choose from. And yet, in this article we will consider the most common material - traditional asbestos-cement slate.

Among the advantages of this material are:

- High strength slate roofs - despite the impact fragility, the slate roof copes with loads perfectly, and in some cases even withstands the weight of a person.

- Durability and corrosion resistance. Unlike metal-based coatings, slate is not afraid of corrosion from condensation and precipitation.

- Insignificant heating in hot weather (this does not apply to painted slate, as well as to non-asbestos slate of dark shades - they heat up quite strongly in the heat).

- Incombustibility, and as a result - fire safety.

- High rates of hydro-sound and electrical insulation.

- Long service life of slate - a slate roof can serve you for quite a long time, so you do not have to cover the roof for several decades.

In addition, the slate roof can be easily repaired without complete dismantling - it is enough to replace the damaged sheets with new ones, and the roof can be used again.

All of the above properties of slate, along with the already mentioned low cost, make it so popular.

Cons of the material (Footnote 2):

- water resistance decreases over time

- the edges of the sheet are rather fragile,

- in places where the shadow most often falls, lichens and mosses can form,

- asbestos is harmful to health.

As we said at the beginning of our article, the technology of slate work is quite simple. You can quite manage the arrangement do-it-yourself slate roofs, but it would be better if you have one or two assistants.

This is primarily due to the fact that slate sheets are quite large, and it is quite difficult to move them alone.

In addition, relatively fragile slate can be damaged by awkward movement - and with an assistant to insure you during transportation and installation of slate, the risk is minimized.

Work Safety and Precautions

Despite the seeming simplicity of working with slate, you should not forget about some points.

They are connected, first of all, with safety precautions, as well as with the necessary precautions to avoid marriage in work and slate battle.

- So, when cutting slate (whether with a hacksaw or a circular saw), in order to avoid getting asbestos-containing dust into the eyes and respiratory organs, it is imperative to use personal protective equipment - goggles and a respirator.

Note! When trimming, slate sheets with a length of less than 0.6 m should not be left - otherwise the mechanical characteristics of the roofing material are seriously violated, and its strength is significantly reduced. Therefore, if necessary, it is better to remove the excess length with a large overlap. An exception is the “slate tile” laying method, when slate sheets are cut into fairly narrow strips.

- It is better to treat a fresh cut line of a slate sheet with water-dispersion acrylic paint - this is how we protect slate from further separation.

- You should not move on the slate roof in shoes with hard soles and shoes with metal heels - this can cause damage to the slate.

Roof preparation for slate installation

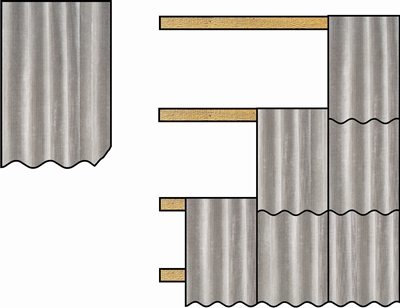

We lay the slate on a specially prepared roof lathing.

It is optimal if, when erecting the crate, we take into account the size of the slate sheet, and fasten the bars of the crate in such a way that the slate for the most part fits entirely, without trimming:

- The optimal step of the crate under slate is 0.70 - 0.75 m. Most often, bars with a section of 60x60 mm are used for the construction of the crate.

- In the event that thinner laths are used for lathing, they should be installed more often - two beams per sheet of slate roofing.

- We form the ridge part of the slate roof from a 60x120mm beam and a 60x150mm board (we lay them close to the ridge beam itself).

- A continuous crate for slate is laid at a distance of at least 0.5 m from the ridges, ribs and roof valleys. For a continuous crate, we use an edged or tongue-and-groove board 60x200 or 60x250mm.

- Without fail, waterproofing material is laid under the slate.

Note! Slate is laid on roof slopes, the slope angle of which is in the range of 10 - 250.

Fasteners

To date, various sources recommend using one of two types of fasteners with which the slate is attached to the crate:

- Slate nails

- Screws for slate

Each of these elements has its own advantages and disadvantages. Special nails are used for slate - at least 120-150 mm long, with a wide galvanized hat.

The screws must also be long enough, while they must be equipped with a washer and a sealing rubber gasket.

On the one hand, fastening slate to nails is much faster.

However, if everything is done according to the rules - namely, do not drive nails into the slate sheet directly, but pre-drill holes in it with a drill - then the time gain will be minimal. Thus, we can say that the choice between nails and special slate screws is purely a matter of taste.

Arrangement of a slate roof

Slate - wavy or flat - is laid and fastened to the roof sheathing according to certain rules:

- We stretch a cord along the eaves, which will serve as a guide for laying the first row of slate.

- If it is planned to install a gutter, a special bracket for slate and a bracket for the drain are also mounted here.

- We lay the slate sheets on the crate in such a way that the overlap is on the leeward side - this is how we protect the roof from wind damage (the wind does not blow under the slate sheets and does not tear them off).

- We lay the sheets, starting from the gable overhang. We gradually mount the slate sheets, moving up and to the side.

- The horizontal overlap when laying slate should be a whole wave. Lay vertically with an overlap of at least 15-20 cm.

- For each of the sheets (with the exception of the extreme, ridge and cornice sheets), be sure to trim the corners diagonally. We paint over the cut line so that the slate sheet does not exfoliate.

Note! It is impossible to break off, or even more so - to break off the corners in any case.

- Slate sheets are fastened with nails or self-tapping screws not to the stop, but in such a way that the sheets are fixed and do not hang out. We fasten the eight-wave slate into the second and sixth waves from the overlap, the seven-wave slate into the second and fifth.

- In no case should the nails for fastening the slate be bent from below, since the slate sheets are displaced in the vertical plane due to temperature deformations, and bent nails can cause cracking of the slate.

There is nothing complicated in the above technology. And yet, despite the seeming simplicity, it is necessary to carefully lay the slate - the life of your roof in this case will be much longer!

Did the article help you?