Asbestos-cement sheet has been one of the main roofing materials for many decades. It is produced in accordance with the standards, therefore, for example, the weight and size of 8 wave slate from different manufacturers will be exactly the same.

This is convenient, because when designing a building, the entire roof, including the parameters of the rafters and battens, can be calculated with an accuracy of up to a centimeter. You can plan the amount of material, and estimate the costs. How sheet dimensions affect the roofing device - later in the article.

Since the asbestos-cement coating has been produced and used in construction for a long time, the dimensions of the slate have been unified during this time, and have become the most optimal.

In this case, several factors are taken into account, which sometimes conflict:

- Sheet size - It is, of course, convenient for roofers to cover as large an area as possible with a unit of material.

However, oversized slate will have a fair amount of weight, which will require a reinforced truss system. In addition, physical endurance will be required for workers. Too large sheets are also inconvenient for roof sections with complex terrain - the material is consumed at high cost - Strength - requires an increase in thickness, possibly - reinforcement (as is done in the West). However, both increase the weight of the roof and increase the cost of the material.

- Density - mainly affects water resistance, although it is quite closely related to strength. The same trouble - you have to pay for it with a lot of weight. (For a flat pressed material having a slate sheet size of 1200x3000 mm, the weight will be almost 350 kg).

If you do not take into account the various ondulins and euroslates, then, according to the "classic" technology, the sheet is produced from two types of mixtures:

- asbestos-cement – based on cement and water with the addition of up to 10% asbestos fiber

- asbestos-free - from the same cement, with the addition of cellulose and polyacrylates

In general, their operational characteristics do not differ much, but the non-asbestos version is considered more environmentally friendly. Regulates all the main characteristics that slate GOST 30340-95 “Asbestos-cement corrugated sheets” should have.

Advice!

For roofs with a small area or a complex configuration, 7-wave slate is better, since in this case the amount of waste from cutting material is reduced.

For even roofs, especially for large areas, the size of eight-wave slate is optimal, which reduces installation time and roof weight (this is ensured by fewer overlaps in horizontal rows)

There is also a standard for straight slate: GOST 18124-95 "Asbestos-cement flat sheets". It is clear that wave slate differs in the number of waves (according to GOST - 6,7,8, but now they are also producing a 5-wave modification), and both flat and wavy - in thickness.

For the curly version, these are 5.2 and 5.8 mm for 7 and 8-wave, and 6 and 7.5 for 6-full, for straight non-pressed - 6, 8, 10 and 12 mm.

Flat pressed slate, in addition to the same modifications, is produced with a thickness of 16, 20, 25, 30 and even 40 mm. Naturally, with an increase in this parameter, the mass of slate, depending on the size of the sheet, will also weigh:

Slate type Thickness, mm Sheet weight, kg

Slate of 7 waves. gray 5.2 18.5

Slate of 7 waves. gray 5.8 23.0

Slate of 8 waves. gray 5.2 20.6

Slate of 8 waves. gray 5.8 26.0

Slate of 7 waves. color 5.2 18.5

Slate of 8 waves. color 5.2 20.6

All figures are given for size 8 wave slate (width) - 1125 mm, seven-wave - 980 mm, with a length of both 1750 mm

Flat unpressed sheet:

Mark and size Thickness Sheet weight, kg

LP-NP 3000х1500 12 105

LP-NP 3000х1200 93.6

LP-NP 3000х1500 10 87

LP-NP 3000х1200 70

LP-NP 2000х1500 58

LP-NP 1750x970 31.5

LP-NP 1500х1000 29.0

LP-NP 3000х1500 8 73.5

LP-NP 3000x1200 57.0

LP-NP 2000х1500 49.0

LP-NP 1750x970 24.0

LP-NP 1500х1000 24.5

LP-NP 1750х970 19.0

LP-NP 1500х1000 17.85

The pressed sheet has a mass of a completely different order, since the density of slate is high:

Mark and size Thickness Sheet weight, kg

LP-P 3000x1200 (monolith) 40 348.10

LP-P 3000х1200 (monolith) 30 252.0

LP-P 3000x1200 (monolith) 25 210.0

LP-P 3000x1500 (monolith) 20 180.0

LP-P 3000x1200 (monolith) 20 168.0

LP-P 3000x1500 (monolith) 16 144.0

LP-P 3000x1200 (monolith) 126.0

LP-P 3000х1500 12 106.0

LP-P 3000x1200 94.00

LP-P 3000х1500 10 96.0

LP-P 3000x1200 84.0

LP-P 2000х1500 63.0

LP-P 1500x1000 32.0

LP-P 3000х1500 8 80.0

LP-P 3000x1200 63.0

LP-P 2000х1500 51.0

LP-P 1500x1000 24.5

LP-P 3000х1200 6 47.0

LP-P 1500x1000 20.0

Indicators may vary slightly (within 1%), depending on the specific manufacturer and batch. As is clear from the tables, the standard size of slate of flat modifications is: width 970, 1000, 1200 and 1500 mm, length - 1500, 1750, 2000 and 3000 mm, although GOST additionally allows a length of 2500 and 3500 mm.

However, there is no hard limit on this parameter, and the manufacturer can produce a different length at its own discretion, or at the request of the customer. Although, for example, the dimensions of the eight-wave slate almost always remain standard.

There is one more sheet parameter: this is its texture. The most common options are a smooth surface, a longitudinal microcapillary strip throughout the sheet, or a small “speck” from asbestos or cellulose fibers. Moreover, the size of the slate 8 waves or flat for any texture will be the same.

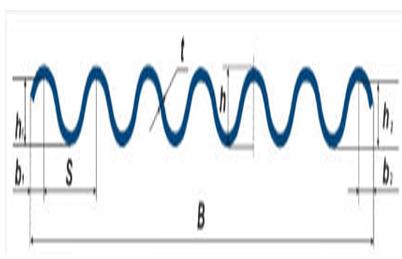

Wave height (vertical distance between the lowest and highest points of the relief) is also standardized by GOST. In this case, three different heights are distinguished: for an ordinary wave, and also for the extreme ones - on the one hand - overlapping, on the other - overlapping. These values look like this:

Slate Wave Height Sheet Profile

40/150 54/200

Private, h 40 54

Overlapping, h1 40 54

Overlapped, h2 32 45

Wave pitch - the distance between the tops of adjacent waves S in the standard is 150 and 200 mm, and is indicated in the slate brand. In the standard, the length of the slate of any profile is 1750 mm, although recently it has also been found in a different size.

However, GOST allows such "liberties", although this value is usually included in the calculations.

Important information!

At the overlapped wave, the height is specially made smaller so that the sheets do not bulge when overlapping. During installation, laying must be done taking into account this difference.

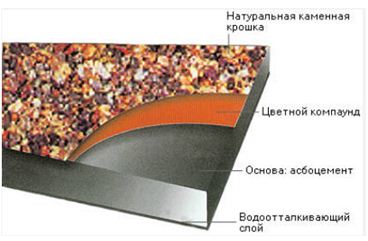

Despite the fact that the main market share in the sales of slate is "classic", manufacturers are actively mastering new materials. You won’t surprise anyone with a painted sheet, although it showed low practicality - the paint burns out too quickly.

However, the problem is solved by applying a protective varnish. Such sheets (flat configuration) can even be used for facade decoration, and manufacturers guarantee coating durability for up to 12 years. From below, an additional water-repellent layer is applied to the sheet, and the surface can be textured or smooth.

A popular method of coloring is the coloring of a mixture intended for the production of slate, using mineral pigments.Such a sheet does not fade, and efflorescence does not form on it (light spots that appear as a result of the destruction of paint under the influence of atmospheric factors).

At the same time, other performance characteristics remain no worse than those of ordinary gray slate, and sometimes even improve. The surface of the paint (both top-coated and pigmented) can be glossy or matte, which implies the presence or absence of additional layers.

But it's not all new

Some manufacturers began to apply additional protective and decorative layers. This seriously increases the operational properties of the material, although, of course, it leads to a significant increase in cost. But under a crumb of natural materials, it is unlikely that anyone will be able to see an ordinary asbestos-cement sheet.

There are also plastered options, and the plaster can be of several types, for example, with a uniform surface, or the “bark beetle” type. Such a slate has dimensions slightly different from the standard: 1500x1200 with a thickness of 8 mm.

Advice!

Although according to SNiPs, the slope of a slate roof should be at least 12%, roofs with a laying in the range of 20-40% work best.

The direction of asbestos-free, cement-fiber slate is also actively developing. In addition to being considered more environmentally friendly, such a sheet is also almost a quarter lighter than the traditional one, and has greater strength.

Polymer additives increase the guaranteed service life up to 50 years. It can have the same wave dimensions as a regular slate, or be produced according to the European standard - with a wave step of 17.7 cm, have its height of 5.1 cm.

It is impossible not to mention the so-called "scales" - tiles made of standard asbestos concrete, where the dimensions of the slate are 400-600 mm. They are useful for complex roofs of houses with many external and internal joints, having a large number of roof structures or architectural elements.

The thickness and other properties, in addition to linear dimensions, are exactly the same for scales as for ordinary flat slate.

And yet, the main working properties of any roofing material are associated with its installation on the roof. The question arises, which asbestos-cement sheet is better - flat or wavy? It is definitely difficult to answer it. The most reliable can be considered a two-layer coating of flat slate with a shift of half a sheet in the horizontal rows of each layer. However, its cost and weight will be quite high.

With a single-layer coating, the sheets are overlapped, which worsens the waterproofing of the roof. Therefore, having a little more weight, but the same dimensions, wave slate looks preferable. This is also confirmed by statistics - flat sheet coatings are now quite rare.

In general, although asbestos-cement materials have many disadvantages, this material, especially in individual housing construction, is still very widely used.

After all, it also has a lot of advantages, and the size of a slate sheet, its weight, density and other characteristics can be rationally selected for almost any pitched roof. You should not expect excessive quality from the old slate, but for its price it fulfills the planned functionality in full.

Did the article help you?