Sheet slate - the dimensions of which differ depending on the brand, are quite often used for roofing work in the construction of residential buildings, for the construction of ceilings, fences and other structures. The demand for this material is growing from year to year. Today, flat and wavy slates are produced in various colors and structures. Some types of sheet slate are described in this article.

Sheet slate - the dimensions of which differ depending on the brand, are quite often used for roofing work in the construction of residential buildings, for the construction of ceilings, fences and other structures. The demand for this material is growing from year to year. Today, flat and wavy slates are produced in various colors and structures. Some types of sheet slate are described in this article.

Categories of sheet slate

The category of sheet roofing materials is ideally emphasized by slate, although other roofing materials are crowding it in the roofing market.

However, many types of slate are still popular in the economy class:

- asbestos slate - a classic coating;

- bitumen sheets - made from synthetic fibers;

- iron slate, which is based on steel with a slate wave profile;

- polymer slate - PVC sheets.

Bituminous fiber slate

Bituminous fiber roofing material is a modern alternative to classic slate.

It is based on fiberglass or processed cellulose. During the manufacturing process, bituminous impregnation, a paint or polymer layer is applied to the base.

Well-known brands of this sheet material include ondulin and euroslate. The shape of the profile of these roofings and laying methods differ little from the classic asbestos material.

But in comparison with it, bitumen sheets have the following properties:

- much easier;

- more durable.

The light weight of the sheets makes it possible to lay them on top of the old coating without the need to strengthen the truss structure.

If the installation rules are observed, bitumen-fibrous sheets can withstand strong wind (55 m/s) and snow (300 kg/sq.m) loads. In addition, the bituminous coating has good sound insulation.

PVC sheets

Is gaining distribution plastic slate sheet of polymer (PVC), made by extrusion, followed by shaping the corrugations by vacuum forming.

The advantages of PVC roofing sheets include:

- light weight;

- strength;

- durability;

- resistance to alkalis and acids;

- variety of colors.

Characteristics of polymer sheets:

- per 1 sq.m weight is 4.2 kg;

- bending strength per 1 sq.m is more than 500kgs;

- use temperature -40-+80 degrees;

- fire resistance.

Attention.Polymeric corrugated slate is designed for laying on a roof with a slope angle of more than 15 degrees.

metal slate

Galvanized slate has become widespread due to the following indicators:

- ease of installation metal slate;

- durability;

- manufacturability;

- good operational properties;

- affordable cost.

Iron sheets are a frost-resistant roofing material that is resistant to mechanical damage. Their lightness and flexibility makes it possible to carry out roofing work on roofs with a complex architectural configuration.

Attention. However, this slate is susceptible to corrosion when used in acidic and alkaline environments. To protect this material, it is necessary to use paints and varnishes for the metal profile.

Asbestos sheets

Asbestos sheets were and remain popular. In addition to frost resistance, density and other characteristics, it has sheet slate - dimensions determined by the requirements of the standards.

The classic eight-wave sheet is produced with a length of 1.75 m, a width of 1.13 m, a thickness of 4.8 mm, a wave height of 40 mm, a wave pitch of 150 mm, a mass of 20 kg, and a width of the overlapped edge of 37 mm. .

In our time, sheet flat slate is widely used, which is distinguished by fire resistance, durability, and strength. This material is the basis for the creation of partitions, balcony railings, wall panels, utility structures.

Flat sheets have the following properties:

- resistance to aggressive environment;

- affordable cost;

- soundproofing;

- ease of installation;

- the possibility of decoration.

Factory production of slate is carried out in compliance with technological standards and control of production processes.Homemade slate is made by this method:

- 4 sheets of used slate, plastic wrap, cement, cotton canvas are taken.

- Cement is calculated - 50kg per 15 sq.m of film.

- Cement milk is diluted and a cotton canvas prepared according to the size of the slate is soaked in it.

- A film is spread on the horizontal surface of the used sheet - two layers of impregnated cloth - two layers of film - a double cloth. So 4 rows fit;

- A film is laid on top and pressed down with another slate sheet.

- After drying, the layers are disassembled - 6 sheets are obtained.

Attention. Homemade sheets must be treated with a special paint to increase their durability in adverse conditions of use and reduce surface porosity.

Laying sheet materials

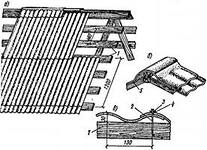

The installation procedure for sheet slate of any category is similar to asbestos-cement slate. The process flow is as follows:

- A crate is being prepared, the size of which contributes to the complete longitudinal and transverse laying of sheets;

- During installation, a protrusion of sheets beyond the crate is formed: from the eaves - 300mm, from the pediment - 120mm;

- Under bituminous sheets on roofs with a slope of not more than 10 degrees, a continuous crate is made;

- The amount of sheet overlap depends on the roof slope: 10 degrees - end overlap 300mm, side 2 waves; 15 degrees - end 200mm, side overlap 1 wave;

- Laying is carried out from the bottom up;

- Odd rows are stacked from whole sheets, and even from halves;

- Fastening additional elements of the roof are placed according to the following rules: a five-wave sheet - in the 2nd and 4th wave, a six-wave sheet - in the 2nd and 5th wave, an eight-wave sheet - in the 2nd and 6th wave;

- Bituminous slate is fixed at the ends of the sheet and on both sides of the side overlap;

- Fastening must be placed with optimal density to the sheet. With a weak fastening, the slate will vibrate during wind loads, and if it is too tight, it will crack. Together with the fasteners, rubber gaskets are used.

Particular attention is paid to the roof ridge. For its device, shaped parts are produced. Also, a skate for slate can be made independently in this way:

- bending at an angle of a steel sheet;

- chipping boards at an angle.

The height of the ridge should provide sufficient overlap on the slate sheet to prevent frontal wind blowing. Usually skates with the following dimensions are used:

- height 2m;

- width 13, 17 or 20cm.

Advice. For high-quality installation of the ridge, use stainless fasteners, for which holes are pre-prepared. On complex roofs, the joints of the sheets on the ridge are equipped with a ventilation tape to protect against the formation of condensate drops.

Advantages of using sheet slate

The device of sheet slate on the roof has the following advantages:

- the price of slate is lower than metal or tiles;

- low labor costs and maintenance of the roof;

- resistance to the effects of biological components;

- not susceptible to corrosion;

- low thermal conductivity;

- high frost resistance;

- strength;

- water resistance;

- duration of operation;

- ease of machining;

- ease of installation and repair.

Thanks to these advantages, slate proves its worth in the field of construction and roofing.

Did the article help you?