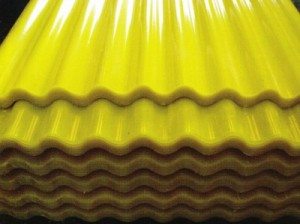

Every year more and more perfect samples appear on the market of building and roofing materials, facilitating installation work and allowing you to create attractive and reliable coatings. One of these materials is plastic slate.

Every year more and more perfect samples appear on the market of building and roofing materials, facilitating installation work and allowing you to create attractive and reliable coatings. One of these materials is plastic slate.

Classical slate made of asbestos cement is very popular, as it is quite reliable and, at the same time, affordable material.

However, if we compare ordinary and plastic slate, then the comparison will definitely be in favor of the latter.

Advantages of plastic slate

It must be said that plastic slate is an almost ideal material for arranging a roof when you want to create an attractive, environmentally friendly and reliable coating.

Here are the main benefits this roofing material:

- Easy installation. Of course, when laying the material, a number of rules should be observed, but the installation of a plastic roof requires much less labor than the use of other materials.

- Ecological purity. One of the main disadvantages of classic slate is the presence of asbestos in its composition. This material is environmentally harmful, and it is for this reason that many homeowners refuse to purchase slate. If you use pvc slate, then no health concerns can arise, since the polymer material is environmentally friendly.

- Polymeric materials are not subject to corrosion, they are resistant to atmospheric influences and other adverse factors. Thus, pvc slate allows you to create durable roofs that do not require constant monitoring and periodic repairs.

- Polymer-based slate is available in a variety of colors, so it does not require painting and allows you to implement any design ideas.

- In addition, polymer slate is a fairly light material, which not only facilitates the task of lifting it to the roof, but also saves on the construction of truss systems, since no reinforcing structures are required to be installed.

- The polymer material is quite easy to cut and bend, so it can be recommended for covering roofs of complex shape.

- In addition, pvc plastic slate is resistant to prolonged exposure to solar radiation, to temperature changes, to snow load and hail. This type of slate perfectly copes with quite significant wind loads.

- The surface of the plastic slate very smooth, therefore, as a rule, dust does not accumulate on it, and accumulated dirt is easily washed off with water.

How to mount a roof using plastic slate?

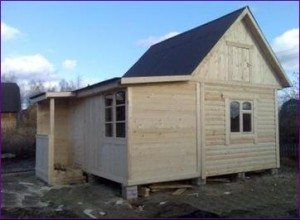

As a rule, plastic slate is used for the construction of galleries, sheds or gazebos. In addition, this material is almost ideal for covering the roof of a winter garden. How is it being installed?

Stage one. Building a crate

For construction roof battens you can use boards with a section of 50 by 50 mm. As a rule, it is recommended to do a lathing step of no more than 350 mm, and each board is attached to the rafters with two nails. The first batten board is installed at a distance of 5 cm from the roof eaves.

If plastic slate is used to cover the roof, then a metal frame is often used as a crate.

If the crate is built of wood, then all elements should be pre-treated with flame retardant and antiseptic solutions. .

Stage two. We stack the sheets

You must adhere to the following recommendations:

- When choosing the direction of laying sheets, it is necessary to take into account the wind rose in the area and perform laying in the direction opposite to the prevailing winds.

- Laying the second row is carried out with an offset.That is, you need to make sure that the joint of the sheets in the first row falls in the middle of the sheet located in the second row. If this condition is met, it will be possible to avoid a fourfold overlap device.

- If for some reason it is impossible to stack the sheets with an offset, then in this case, it is required to trim the corner of one of the sheets, making a cut at an angle of 45 degrees.

- When laying plastic pvc slate, it should be remembered that the capillary groove of each sheet must be covered by the next sheet of material.

- The size of the side overlap when laying the material is the width of one wave.

Stage three. Coating sealing

When mounting polymer slate, it is necessary to make the gaps of the waves impervious to moisture. To solve this problem, it is recommended to use sealing gaskets.

The installation of such gaskets will help seal the eaves and protect the roof from the ingress of water, drafts and dust.

And in order to avoid the formation of condensate under the roof, it is necessary to take measures to vapor barrier the interior of the premises.

To do this, use special membrane materials that prevent warm damp air from penetrating into the roofing space.

Stage four. Sheet fasteners

Before you fix the sheets thoroughly, you need to make sure that the side and end overlaps are made correctly. In order to facilitate the process of fastening plastic slate sheets, you can stretch the twine crates along the lines of the beam.

Plastic slate sheets, just like classic slate sheets, are attached along the wave crest. For fastening, it is necessary to use carnations with a notch and a special anti-corrosion coating.

Advice! It is best if a hole of the appropriate diameter is drilled in the slate sheet before installing the nail.

When fixing a plastic slate, it is very important to prevent constriction. The head of a properly fixed nail should not be sunk into the plastic surface. In no case should the wave itself be deformed in height.

A plastic variety of slate can be used for roofing, the angle of inclination of which is 5 degrees or more.

When laying sheets, one should not forget that it is necessary to form a cornice overhang 5 cm wide.

How can you create a tiled effect?

Using plastic pvc slate, you can create a coating that will imitate tiles laid on the roof.

Advice! This installation option is not recommended for flat roofs, it can be used if the angle of inclination of the slopes is more than 15 degrees.

When performing such a coating, slate sheets are sawn into strips with a width of 400 to 600 mm. Then these strips are laid on the crate with a step, if measured along the axis of each strip, in 200-300 mm.

If desired, you can use multi-colored slate sheets, creating decorative patterns.

It is not difficult to perform this installation, since the sheets of plastic slate are cut very easily, without the use of any special tool. However, it should be borne in mind that a large number of joints leads to a decrease in the degree of tightness of the coating.

Conclusion

So, plastic slate is a convenient material for roofing. A huge advantage of this type of slate is its environmental friendliness.

In addition, installation work on laying slate is so simple that they can be done on their own, which will significantly save the construction budget.

Did the article help you?