Do-it-yourself roof lathing is not at all difficult, but in order to avoid “misses”, you need to know some standards and nuances in this work. For example, two boards are nailed close to each other near the ridge itself, which makes it possible to fix a ridge of different widths.

Do-it-yourself roof lathing is not at all difficult, but in order to avoid “misses”, you need to know some standards and nuances in this work. For example, two boards are nailed close to each other near the ridge itself, which makes it possible to fix a ridge of different widths.

The beams and boards of the crate must be fastened with nails having a length of three thicknesses of the crate timber, since under load the nail can break out due to the deformation stresses of the boards.

The main functions of the roof are as follows:

- excellent protection of the structure from environmental influences;

- good sound and heat insulation;

- excellent aesthetic features.

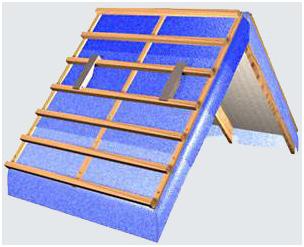

In the construction of the roof, an important role is played by the roof lathing, which is the main element of the truss system.Roofing waterproofing is laid on it, and besides this, the material of the crate depends on the type of roof.

It is made from the following materials:

- bars;

- boards;

- tesa.

Lathing in a private house

During the construction of any building, it is necessary to install a crate with high quality, which plays a major role in the construction of both the roof and hip roof truss system. The type of lathing often depends on the materials, as well as on the type of roofing.

Very often they make a continuous crate, while the boards are laid on the rafters horizontally to the roof ridge. But sometimes the best option is when boards or bars are first laid on the rafters horizontally to the ridge every 50-100 cm, and then boards are laid on the laid bars along the slope, that is, from the ridge to the overhang.

Lathing for roll materials

When the roll coating is glued to a wooden flooring, the crate can be double or solid (recommended to use tongue and groove boards).

The first layer of boards is laid in discharge with double flooring, and after that it is very dense on it - wooden slats with a width of 5-7 cm and a thickness of 2-2.5 cm are stuffed one to one, strictly at an angle of 45 degrees with respect to the working floor - with double flooring.

The boards must first be soaked with an antiseptic.

The main deck must meet the following requirements:

- there should be no sagging, bumps and protruding nails;

- it should not sag under human weight;

- the flooring should not have gaps (if the gap is more than 6 cm wide, then it should be sealed with strips of roofing steel);

- for flooring, the boards should have the following dimensions: width - 10-15 cm, thickness not less than 25 cm (if wider boards are used, then in order not to warp them, it is recommended to split them along the length);

- when installing flooring, only dry material should be used;

- it is desirable to place the joints of the boards on the rafters in a checkerboard pattern, thus roof covering with ruberoid will be of good quality.

To your attention! Closer to the edges of the boards, nails should be driven in and it is advisable to sink their hats into the wood. Frontal boards with rounded edges are nailed to the ends of the overhangs so that rolled materials can be bent. And also along the entire length of the ridge, a strip of roofing steel 30 cm wide should be fixed for sheathing the top of the roof.

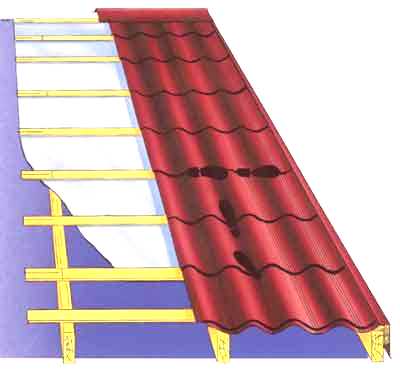

Sheathing device for tiles

Today, many people use metal tiles as a roofing material and often wonder how to make a roof sheathing for such a coating. The crate is a frame made of gratings on which the roofing material will be laid.

When constructing a roof with a two-layer coating or heavy stamped tiles, edged bars are used that have a section of 6x6 cm, with a single-layer coating, bars with a section of 5x5 cm or 5x6 cm are used.

The cornice bar for such a coating should be used very wide, since it should be 25-30 cm higher than the ordinary ones.

Sometimes, instead of such a bar, a thick board is used for the crate with a leveling rail already nailed. Such bars should be laid using a template.

The step of the crate for the metal tile is calculated based on the type of material and dimensions. One step is the distance between the far and near edges of the boards.

Between the first and second board, the step of the crate should be slightly less than the next. You should be aware that the size of the gutter affects the size of the crate step.

Sheathing for tiles is significantly different from sheathing for other materials, and only a calibrated solid board should be used so that it is the same length and without drops.

Steel roof sheathing

Under such a roof, the crate can be sparse or solid. Sparse is made from bars that have a section of 50x50 cm, as well as from boards 50x120 cm -14 mm and solid - from boards having a thickness of 30-40 cm.

Under this type of roof, the crate should be flat - without recesses and protrusions. The durability of the structure depends on the correct installation, and a small deflection of the sheets can weaken the density of the folds. The bars should be spaced 2-2.5 cm apart.

Approximately every 1.5 cm, boards of the same thickness are nailed as bars that are up to 14 cm thick, since wider boards can warp. Skate - the top of the roof is knocked down from boards having a width of up to 20 cm. Such a crate should turn out to be reliable and durable.

Lathing under a soft roof

To date, soft roofing is very popular, and an important detail is the lathing in the device of such a roof. The crate is made in two layers in order to form a continuous coating.

After the first layer is completed, a smooth layer should be laid on it and kinks and friction of the soft tiles should be avoided. Therefore, the installation of the crate should begin with the frame.

After that, it is necessary to lay a layer of roofing plywood on it, which must first be impregnated with a special waterproofing mixture, and after that we can assume that the crate for the soft roof is ready.

Sheathing for slate

For this type of crate, two types are used: single-layer and two-layer. The first is laid on the rafters parallel to the ridge, in steps of 0.5–1 meter.

But most often they use a continuous crate, in which the bars are nailed to dry boards, which are impregnated with an antiseptic.

How to make a roof sheathing under slate correctly? It is usually made of wooden beams, placed across the rafters. For ordinary corrugated sheets, the distance between the bars should be half a meter.

For a wavy unified profile, the distance should be maintained in increments of 0.8 meters. In this case, the section for sheets of the first type, the section of the bars should be 5x5 cm, and for the second - 7.7x7.5 cm.

Tip! Each slate sheet should be supported by three bars, and the eaves bar is made much thicker or raised with special spacers. Even bars are made 30 mm thicker than odd ones, which ensures the most dense overlap of sheets along, and also evenly distributes the load on each sheet. Solid wooden flooring is made on a ridge, overhangs, in grooves.

The sheets are laid from bottom to top, mostly from right to left, the top row overlaps the bottom row by 12-15 cm.This overlap can be increased so as not to cut the sheets, but by choosing the entire distance from the ridge to the overhang.

It is recommended to make an overhang from roofing steel, and then lay slate sheets. On the overhangs, the sheets should be fixed with steel anti-wind brackets.

If the roof structure has an inclination of 30 degrees in places of overlap, then the sheets should be laid on a special mastic. The heads of slate nails and other fasteners should be coated with an anti-corrosion compound. Nails are passed through the crests of the waves.

Did the article help you?