In this article, we will take a closer look at how to perform roof insulation from the inside. This will allow you to turn the attic into living space yourself or just make your home warmer and more comfortable.

Roof insulation technology

Roof insulation can be divided into five main steps:

Stage 1: preparation of materials

First, decide on the choice of thermal insulation material for insulation.

As a rule, for these purposes it is used:

- expanded polystyrene is the cheapest slab insulation with low thermal conductivity. Therefore, it is excellent for thermal insulation of country or garden houses.

I do not recommend insulating the roof of the house with polystyrene foam, in which you will live permanently, since this material has zero vapor permeability. In addition, expanded polystyrene burns well, and at the same time releases dangerous toxins.capable of causing serious poisoning.

Do not forget that expanded polystyrene, although slightly, still absorbs moisture, so vapor and waterproofing should be used together with it;

- penoplex - has higher characteristics than polystyrene foam. In particular, this material is much stronger than foam, but at the same time has a lower thermal conductivity.

Thanks to special additives, extruded polystyrene foam is a low-combustible material. True, this applies only to insulation from well-known manufacturers.

Among the shortcomings, one can single out the low vapor permeability of the material. In addition, the price of extruded polystyrene foam is very high - about 4,500 rubles per cubic meter;

- mineral wool is the best, in my opinion, roof insulation, as it has a number of advantages:

- it is an environmentally friendly material, the only thing to keep in mind is that only basalt wool has this quality;

- does not burn;

- good vapor permeability;

- the price is lower than the cost of extruded polystyrene foam;

- are sold in rolls and in the form of mats, which simplifies the work with insulation.

Keep in mind that mineral wool strongly absorbs wool, so it needs high-quality vapor barrier.

Also, other materials will be needed to insulate the roof:

- antiseptic impregnation;

- vapor barrier;

- wooden slats;

- wooden beams.

Stage 1: floor insulation

If you plan to insulate the roof, it is not necessary to perform thermal insulation of the floor. However, keep in mind that this operation will provide noise isolation. In addition, it is necessary if there is an unheated room on the ground floor, for example, a garage..

The process of floor insulation is quite simple:

- previously, wooden floor beams must be treated with an antiseptic composition;

- then a vapor barrier membrane is laid on the beams and filing;

- then the space between the beams must be filled with heat-insulating material. It must be said that for floor insulation, you can use not only slabs, but also bulk materials, such as ecowool;

- then lay another layer of vapor barrier directly on the beams and insulation;

- for better sound insulation of the ceiling, lay a cork or felt backing on the beams. Polyethylene foam can also be used;

- then the draft floor is performed according to the standard scheme.

If the attic space will not be used as a living space, only the attic floor can be insulated, and the roof should not be insulated.

Stage 3: roof preparation

Before you insulate the roof of the house, you must definitely prepare it by doing the following:

- Start preparing the roof by inspecting the truss system. The design should not contain rotten or cracked parts. If such are found, they need to be strengthened or strengthened;

- then treat all wooden structural elements with an antiseptic. If the roof of a wooden house is being insulated from the inside, wooden gables must also be treated with an antiseptic;

- if the insulation layer is thicker than the rafters, the rafter legs should be increased in thickness by nailing boards or beams to them;

- if waterproofing was not laid during the laying of the roofing material, it must be fixed from the inside. Use a super diffuse membrane for this, which should be attached to the batten and rafters.

This completes the preparatory work.

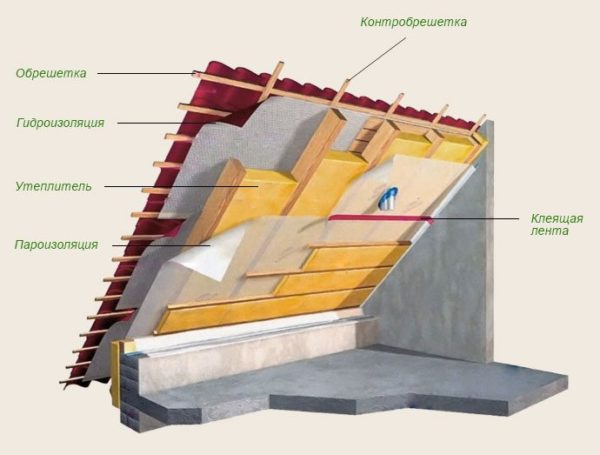

Stage 4: roof insulation

Now you can insulate the roof.

The work is done like this:

- insulation should begin with the arrangement of the gap between the vapor barrier and waterproofing. The gap should be about a centimeter.

So that the vapor barrier membrane does not come into contact with the waterproofing, you need to zigzag the thread between the rafters, tying it to the carnations driven into the rafters, as shown in the photo above. The distance between the nails and the waterproofing should be about a centimeter;

- attach the membrane to the rafter legs, for example, with a stapler. Glue the joints of the vapor barrier with adhesive tape.

In the case of using extruded polystyrene foam, the vapor barrier can be omitted;

- now you need to mount the heater. To do this, insert it into the space between the rafter legs. To fix the insulation, you can hammer nails along the rafters and pull the thread between them in a zigzag pattern.

Pay special attention to the joints of the plates with each other, as well as with the rafters. If there are gaps, they must be foamed;

- then a vapor barrier film is installed, which is attached to the rafter legs;

- at the end of the work, a crate is mounted, which will provide a gap between the casing and the vapor barrier. The crate is a wooden slats that are nailed to the rafters.

It is even easier to insulate the roof during the construction process, i.e. before laying roofing. In this case, a crate is first made from the inside, after which a heater is laid on it from the outside.

This completes the insulation of the roof of the house.

Stage 5: warming the gables

If the house has gables, then they also need to be insulated.

The instruction looks like this:

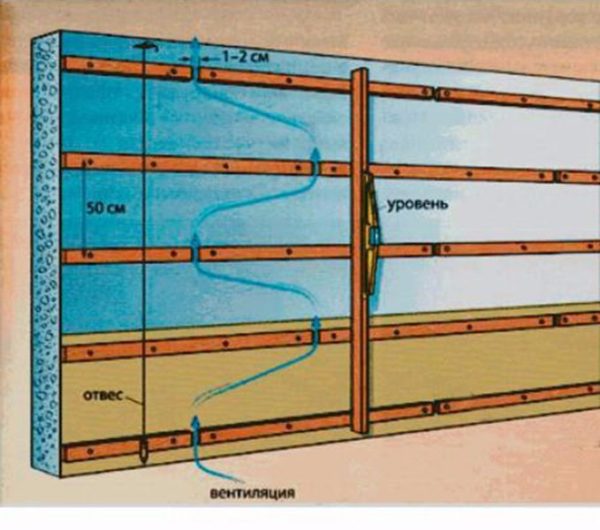

- as with roof insulation, work should begin with the arrangement ventilation gap. For this attach the slats to the gables as shown in the diagram below, i.e. in increments of 0.5 m vertically, and 1-2 cm horizontally;

- then fix the vapor barrier on the rails, be sure to place it tightly;

- Next, you need to install racks. To do this, attach the bars to the rails in a vertical position with a step of 0.5 m.If the insulation is carried out with mineral mats, it is advisable to make the step a centimeter or two less so that the insulation fits tightly and is fixed in the space of the frame.

In order for the racks to form an even vertical wall, first level the extreme bars, and then stretch several cords between them with your own hands. Use the latter as beacons for mounting intermediate racks.

To attach the bars to the rails, you can use metal corners or even suspensions, which are used when mounting the frame for drywall;

- then fill in the space frame insulation;

- at the end of the work, fix the vapor barrier on the racks, and perform the crate according to the scheme described above.

That, in fact, is all that I wanted to tell you about how to properly insulate the roof of a house.

Conclusion

Now you know how the roof is insulated from the inside, and you can safely take on this work yourself. I recommend watching the video in this article. And if some points are not clear to you, unsubscribe in the comments, and I will be happy to answer you.

Did the article help you?