Installation of downpipes is an almost indispensable element of the roofing system. In order for them to function effectively, their design and location must be calculated taking into account the characteristics of the roof. In addition, the operation of the drainage system is affected by compliance with the installation rules. These issues will be given maximum attention in the article.

Selection and calculation

Material selection

The gutter system performs the function of diverting rain and melt water flowing down the slopes of the roof from the walls and foundation of the building. The presence of an effective drain allows you to protect the building from the harmful effects of moisture, so that the house itself, its foundation, and the paths around it last much longer.

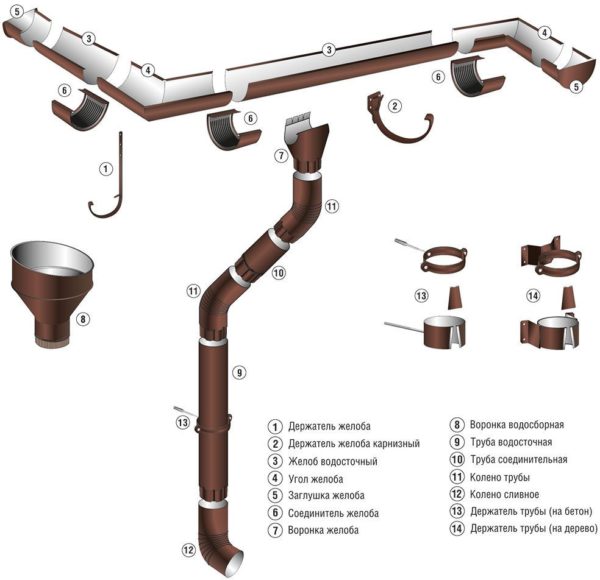

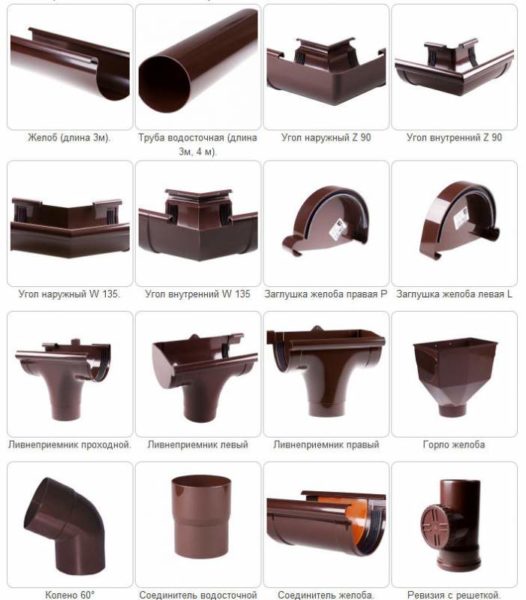

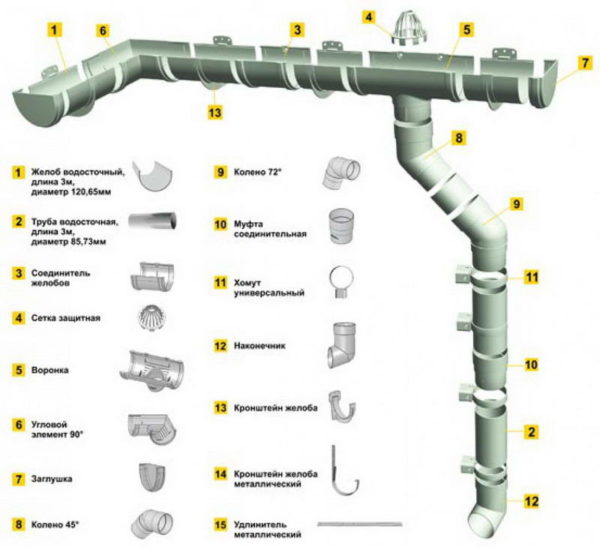

The system is based on funnels, pipes and gutters through which water moves during the runoff. All these elements can be made either from plastic, or from galvanized steel, or from metal with a polymer coating.

Both plastic and metal drainage systems have both pros and cons:

| Material | Advantages | Flaws |

| Metal |

|

|

| Plastic |

|

|

As you can see, the pros and cons of various products almost balance each other. Therefore, it is worth choosing the material from which the drainage system will be made based on the characteristics of the facility being equipped.

Design and calculation of gutters

Installation of a drainage system begins with the calculation of components. We need to decide which pipes with gutters we will use, and how many of them we will need.

When selecting parts, we start from the total area of \u200b\u200broofing slopes:

| Roof area, m2 | Gutter width, mm | Pipe diameter, mm |

| up to 50 | 100 | 75 |

| up to 100 | 125 | 85 — 90 |

| over 100 | 150 — 190 | 100 — 120 |

The number of pipes can be calculated in two ways:

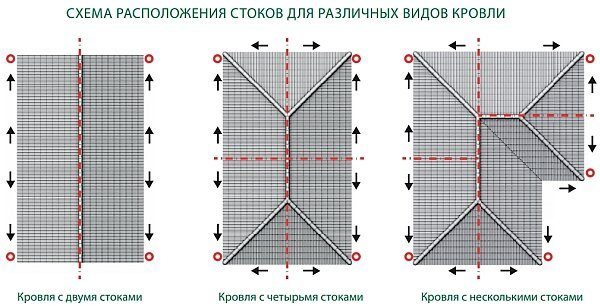

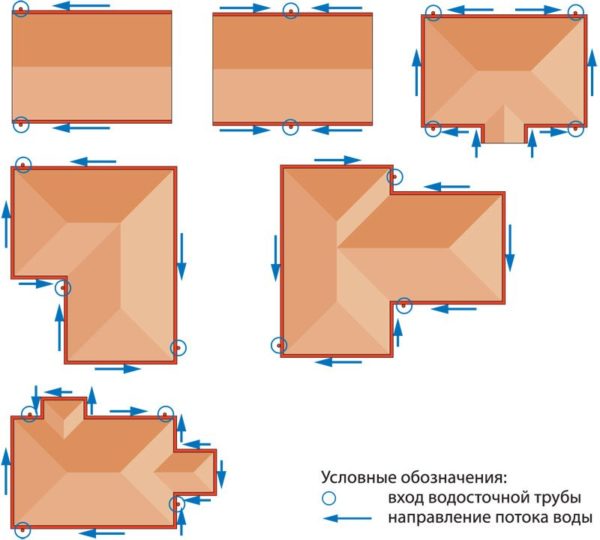

- or at least one pipe per 100m2 of the roof in projection (i.e. not the area of the slope itself, but the area of its base);

- or at least one pipe per 10 m gutter.

You also need to calculate the number of other elements.

- One gutter is installed on each roof slope. The total length of the gutters is equal to the sum of the lengths of the eaves located on the slopes.

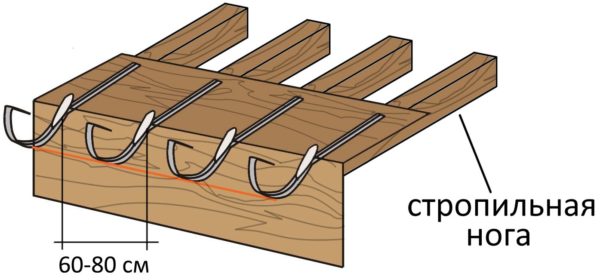

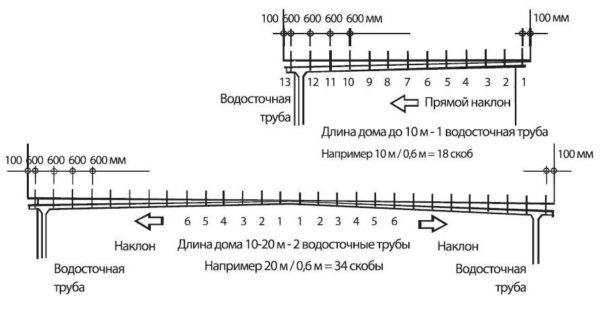

- Brackets for fixing the gutter are placed every 50 - 80 cm, respectively, based on this, and their number is calculated.

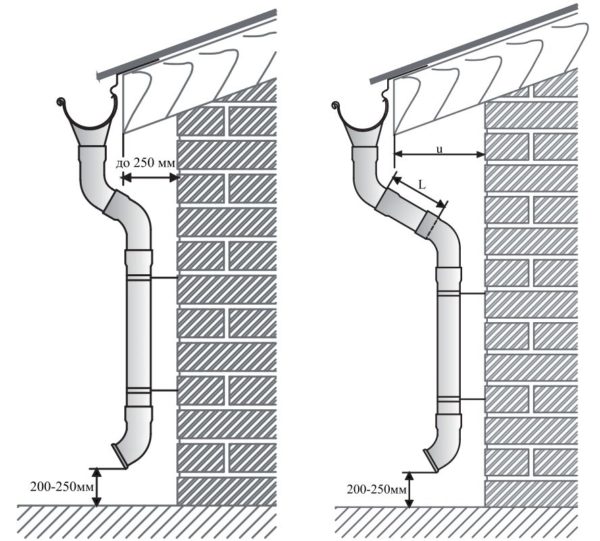

- The height of the drainpipe is taken equal to the distance from the ground to the gutter minus 25 - 30 cm (distance from the drain elbow to the ground).

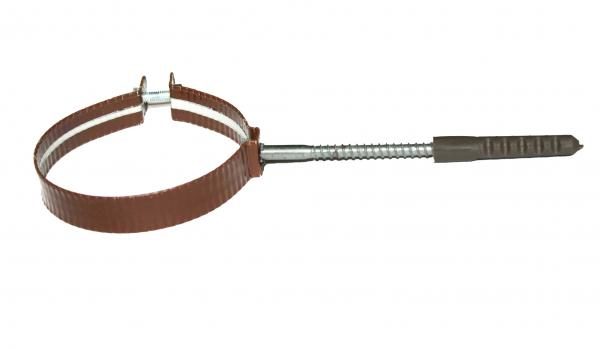

- Clamps for fixing the pipe on the wall are placed to fix the joints of downpipes (as a rule, they have a length of 3 or 4 m), as well as at the junction of the main pipe with the funnel of the gutter and with the drain elbow. The minimum spacing of the clamps is 2 m.

All calculations are rounded up. It is also advisable to choose pipes and gutters of greater length - the fewer connections, the higher the reliability of the system!

In addition, when buying accessories, additional parts are also purchased - plugs, gutter connectors, adapters, etc. Their range and quantity depends on what kind of system you plan to create.

Tools and fixtures

Installing gutters and pipes is not a very difficult task, but it is time-consuming and requires accuracy.

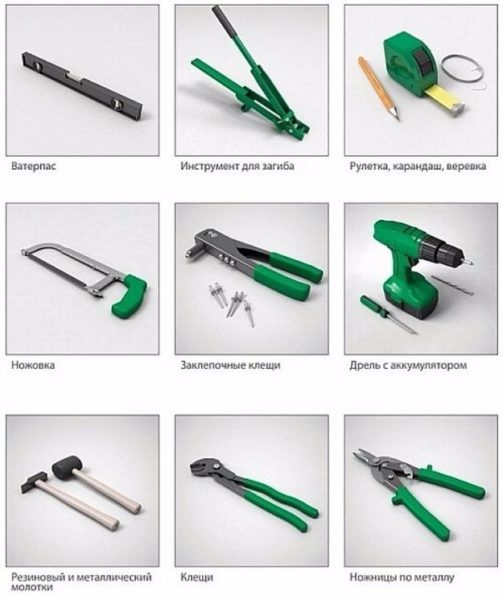

The list of tools that may be needed to solve it includes:

- level;

- roulette;

- plumb;

- screwdriver;

- perforator;

- saw for metal or plastic;

- metal scissors;

- file for cleaning the ends;

- sharp knife;

- hook bending tool;

- hammers (one metal, the second rubber);

- rivet tongs (for mounting metal gutters).

In addition, we will need a high rack or scaffolding, since we will have to work at a height.

Installation of a metal gutter system does not require the use of additional materials. But to connect plastic parts, either special glue is used, acting on the principle of cold welding, or rubber seals.

Mounting technology

Hooks and gutters

Installation of gutters, which are used to collect rain and melt water, begins with the installation of fixtures:

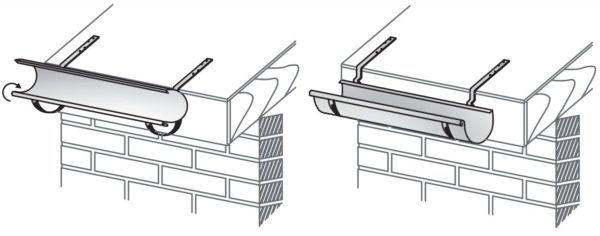

- For fixing gutters most commonly used hooks made of galvanized steel or plastic-coated metal. Hooks can be solid (short, medium and long) or adjustable in length.

- As a rule, the required number of fasteners is selected before installation., lay them out in the order in which they will be installed, and bend them with a special tool. This is done so that due to the bending of the hook, a slope of approximately 2-3 mm per 1 running meter towards the drain is formed.

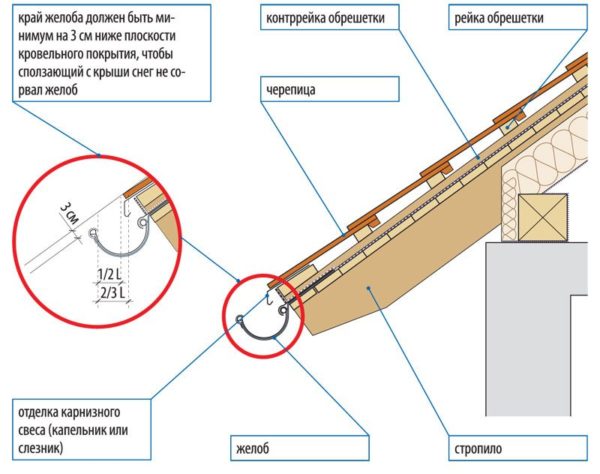

- Also, when bending, we make sure that the gap between the upper edge of the hook and the line continuing the roof line is at least 25 - 30 mm. If you do less. That part of the flowing water will fall past the gutter.

If there is no tool, then instead of bending, you can simply adjust the position of the hooks according to the level.

- The first gutter holder is placed at a distance of no more than 100 - 150 mm from the edge of the roof. Then the brackets are fixed in increments of 500 - 600 mm.For fixing, self-tapping screws are used, which are usually screwed in three pieces.

- It is allowed to mount the hook on the eaves, rafter or edge board of the crate. If roofing material or waterproofing will be laid on top of the part, then a groove is made in the rafter or crate so that the hook does not protrude above the surface.

- Gutters are laid on brackets. In modern models, the front edge of the gutter is fixed with a latch on the hook, which prevents the part from moving.

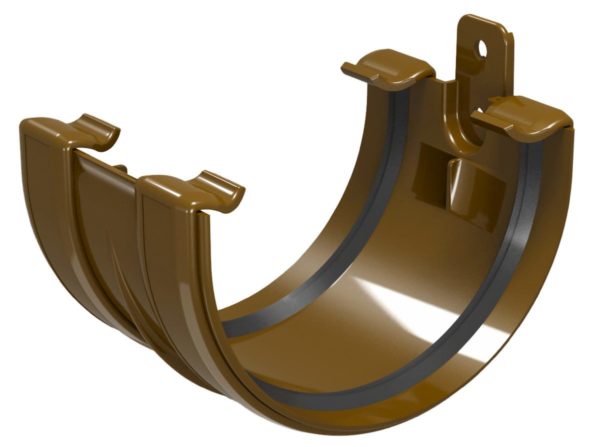

- Between themselves, the horizontal elements of the drainage system are joined using a special part - a gutter connector. Both elements are inserted into the grooves of the connector, and in the case of plastic pipes, they are additionally glued with a special compound.

- Also, metal gutters can be additionally connected using soldering or welding, but this requires specific skills and complex equipment.

- We put plugs on the ends of the connector, which are also sealed.

Installing funnels connecting gutters to pipes is a separate operation.

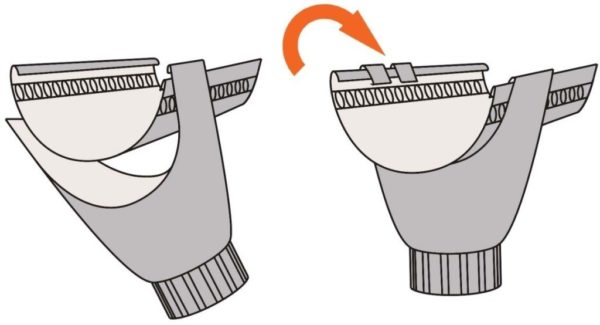

The sequence of actions here depends on the design of the parts used:

- In some systems (most often plastic), the funnel is a one-piece piece with a fragment of the gutter, a drain hole and a vertical outlet. It just needs to be attached to eaves in the right place, bringing horizontal gutters from one or two sides.

At the junction of the gutters with the funnel, no glue is used, and sealing is provided only by rubber seals. This connection allows you to compensate for the linear expansion of the plastic.

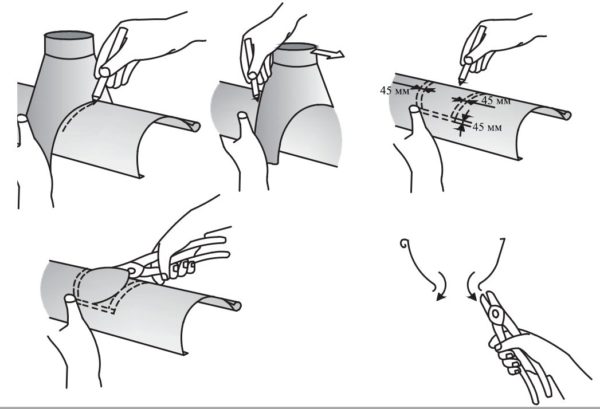

- When installing metal gutters, the funnel is mounted under the gutter. To do this, a hole is cut out in the lower part of the gutter with scissors, the dimensions corresponding to the funnel socket. The funnel itself is attached from below exactly under the cut hole.

- Both metal and plastic funnels can be equipped with gratings that protect the system from falling leaves into the drain. Of course, gratings will not be protected from overlapping pipes with fallen leaves, but if they are present, cleaning will be an order of magnitude less laborious.

Other components of the structure

After the gutters with receiving funnels are mounted, you can proceed with the installation of downpipes.

The installation instruction involves the performance of work according to the following algorithm:

- We install clamps on the walls with dowels to fix the pipe. The optimal clamp installation step is from 1.5 to 2m, taking into account the requirements specified in the previous sections. Be sure to control the verticality of a number of clamps using a plumb line.

- When installing the clamp, we deepen its fastening into the wall so that it is at least 40 mm from the bearing surface.

- We attach one or two knees to the lower edge of the funnel, connecting the gutter to the pipe on the wall. If the roof overhang is of considerable size, then the instruction allows the installation of a straight connecting pipe section with a minimum of 50 mm in each elbow.

- Drain pipes cut to size with a hacksaw. We clean the edges from burrs.

- We fix the pipes to the wall with clampsby tightening the bolts.

- We attach a drain elbow to the bottom of the pipe. When installing a metal system, we fix it with rivets, and when installing it on a plastic pipe, it is enough to use reliable glue.

It is desirable that water from the drain elbow does not fall on the ground or road surface. To do this, either a tank is placed under the drainpipe to collect rain / melt water, or a drainage tray is equipped. It will also be very practical to have the receiving grate of the soil drainage system immediately under the drain elbow.

Conclusion

Installing a drain in accordance with all the rules will allow you to effectively remove moisture from the walls and foundation. If you do not want to entrust this task to hired specialists, follow the recommendations given in the text and video in this article in your work. Any questions you may have can be asked in the comments.

Did the article help you?