Hello. In this article I will talk about how to independently install a chimney in a private house. I am sure that the topic of the article will be not only interesting, but also useful to many readers, since the correct construction of the chimney determines the parameters of performance, efficiency and operational safety of the heating system.

The main varieties and their features

The chimney is an end element in the design of the heating system, which is responsible for the efficiency of exhaust gases removal from the heat generator - boiler, furnace, etc.

Chimneys in accordance with the installation features are divided into the following modifications:

- External add-on modifications – a universal solution that can be used with both forced draft and natural draft appliances;

- Horizontal modifications - are used exclusively in boilers with forced draft;

- Internal vertical modifications - are used mainly with equipment operating on natural draft.

Regardless of which of the listed modifications you will use when installing the heating system, those chimneys, most of which are located indoors, demonstrate the highest operational efficiency.

In accordance with the method of connection to the heating boiler, chimneys are divided into the following types:

- Separate modifications – are installed separately for each heating boiler;

- Combined modifications - outputs from several boilers are connected to one common pipe that goes outside.

According to the design features are distinguished:

- Conventional chimneys with single-layer walls - a traditional, but unsafe solution;

- Coaxial chimneys (sandwich pipe) - differ in better thermal insulation from adjacent building structures.

Installation of a coaxial pipe in a wooden house

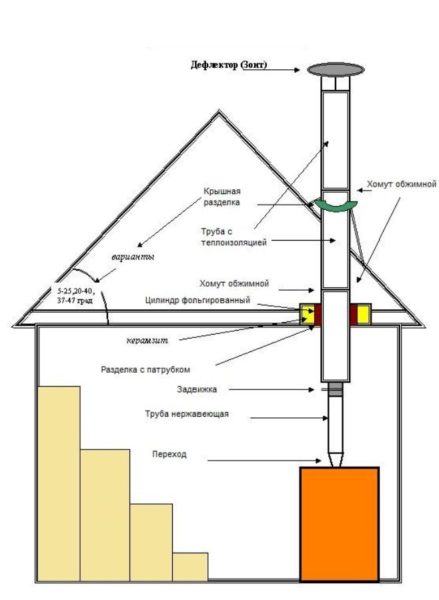

I suggest that you familiarize yourself with how the installation of a sandwich chimney from a modern metal furnace is carried out correctly with the passage of the pipe through the ceiling and roofing system.

The installation work shown in the photo report was carried out in a wooden building, that is, the necessary measures were taken to prevent overheating of adjacent structures during the operation of the furnace.

Since the chimney was planned to be arranged almost close to wooden wall, metal profiles were fixed on the wall with their own hands, between which high-density basalt wool was laid. The thermal insulation prepared in this way was sheathed with Minerite refractory sheet.

Installation instructions consist of the following steps:

- In accordance with the planned location of the furnace, a hole was marked on the floor for the passage of the pipe;

- In accordance with the markings made, a hole was cut out in the ceiling;

- Similar work was done on the roofing pie, and as a result, a through hole was obtained for the passage of a vertical pipe for the chimney;

Modern smoke exhaust systems are manufactured in such a way that heat bridges do not form between their surface and adjacent structures.Despite this, the holes for the pipes must be cut so that they are located as far as possible from the wooden parts of the ceiling or roofing cake.

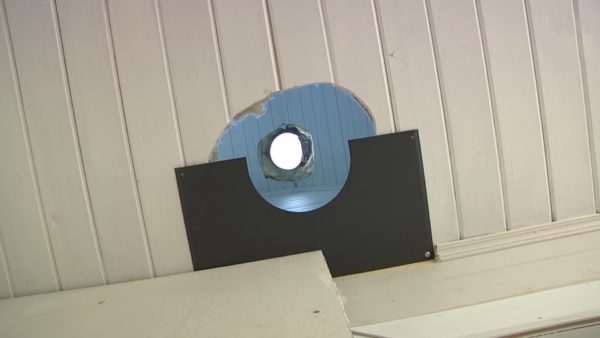

- A decorative casing was installed along the perimeter of the opening in the ceiling, which will prevent the pipe from coming into contact with the ceiling;

- In the lower part, a support element is mounted on which the plug will be fixed;

The calculation of the installation height of the support element is carried out taking into account the height of the flue pipe on the furnace.

- Mark the center of the hole on the wall. From the center down, we measure a distance equal to half the tee that comes with the chimney. We subtract 20 mm from the measured distance - exactly so much the tee will enter the supporting element. At the level of this mark, the upper point of the reference element should be located;

- We install a tee to connect the main vertical pipe and furnace;

- The tee is attached to the supporting element with a clamp with a clamp;

- The upper part of the pipe is attached to the tee and is also fixed with a clamp;

- In the lower part of the support element, we install and fix the plug;

Through the plug, it will be possible to regularly clean the internal volume of the chimney. In addition, a condensate drain is provided in the center of the plug.Condensation is a consequence of the normal operation of the flue system, therefore, under the drain, it is necessary to adapt the connection to the drainage.

- We bring the pipe through the ceiling up through attic to the roofing pie, fixing the connections with the clamps that this chimney model is equipped with;

Once again, make sure that the distance between the pipe and the edges of the cutout in the ceiling is at least 10 cm. If the specified distance is less than necessary, the excess must be cut.

- In the gap between the pipe and the ceiling, we close the cut perimeter with foil and glue it with foil tape;

- Next, we put heat-resistant basalt wool in the gap, which not only does not burn, but also does not shrink, like ordinary glass wool;

- We mount the next section of the pipe so that the edge of the structure is located at a height of 1.5-1.7 meters;

- At the free end of the pipe, we install and fix the gate valve;

- We pass through the roofing pie in the same way as through the ceiling, but on the side of the roof we additionally install a protective casing that will prevent precipitation from flowing into the room;

- A deflector is installed on top of the pipe, which, on the one hand, will prevent moisture from entering the chimney, and on the other hand, will increase traction;

- From the side of the attic, we fix the assembled structure with a clamp on the take-out;

- We close the technological gaps on the ceiling and on the roofing cake with decorative plates;

- At the bottom of the furnace, we install a single-circuit elbow and an adapter for connecting the furnace;

- After connecting the furnace, the installation of chimneys can be considered completed.

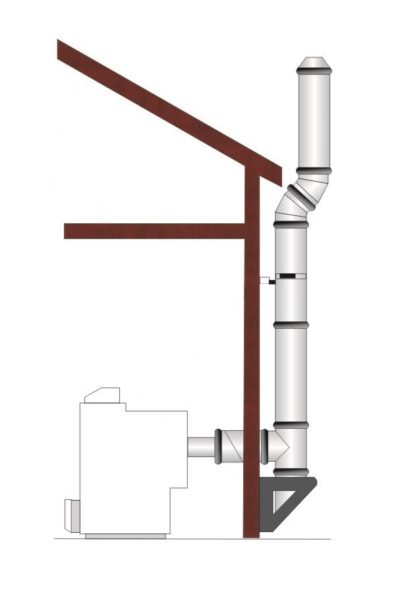

Installing an external chimney

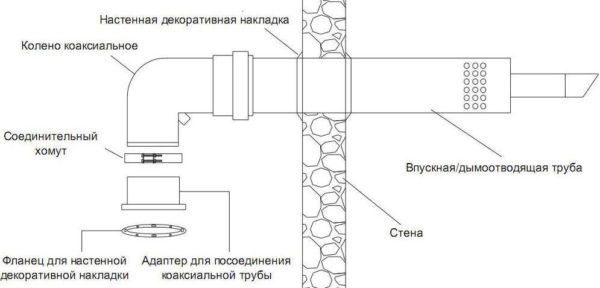

Now let's look at how to install an attached type chimney pipe with passing through a brick wall.

The instructions for the device of the smoke exhaust system are as follows:

- At the initial stage of installation, measurements are taken of the location of the pipe relative to the heating equipment and relative to the floor;

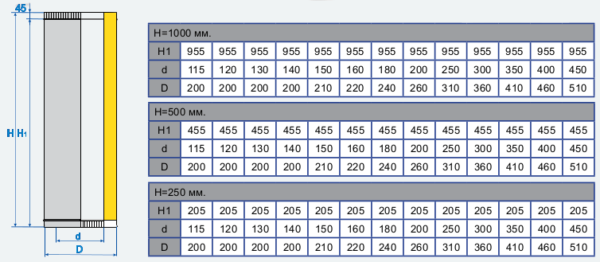

- According to the measurements made, a circle is drawn with a diameter of 30-50 mm larger than the diameter of the outer contour of the pipe;

- Along the perimeter of the marking made, the wall is drilled through;

Given the large diameters of the chimneys, I recommend not to waste time on tedious drilling and punching. Order a concrete diamond cutting service and the necessary hole will be made quickly, accurately and almost without dust. If you think that the price of cutting concrete is high, then this is not entirely true. The number of offers of this service on the market is growing, which leads to a gradual reduction in prices.

- A pipe section is installed in the finished hole;

- The removed pipe is centered so that there is an equal gap along its perimeter;

For centering, I recommend cutting pieces of foam plastic of equal size, corresponding to the difference in the diameter of the hole and the diameter of the outer contour. Further, tucking pieces from different sides, you can align the pipe.

- From the outside, a supporting element is attached to the wall by means of anchor bolts;

- A tee is attached to the supporting structure, which is connected to the through pipe with a central outlet;

- A plug for condensate drainage is installed at the bottom of the tee;

- Tee connections with pipes and a plug are fixed with clamps;

- From the top outlet, two sections of pipes rise up;

- At this height, a holder is installed on the wall, through which the chimney is fixed;

- The rest of the pipe sections are installed;

Please note that the weight of the pipes is considerable, and therefore it is inconvenient and unsafe to work at height from ordinary ladders. I recommend stocking up with sustainable scaffolding for such work.

- At the end of external work, a deflector or a regular umbrella is mounted, depending on the configuration of the selected system;

- In the room, the passage pipe is connected to the boiler through an adapter;

- From the gap between the pipe and the edges of the hole, the previously laid centering foam is removed;

- The gap is filled with basalt wool;

- Further, metal platbands are installed over the gap, which come complete with the selected chimney.

Personal opinion on the choice of coaxial chimneys

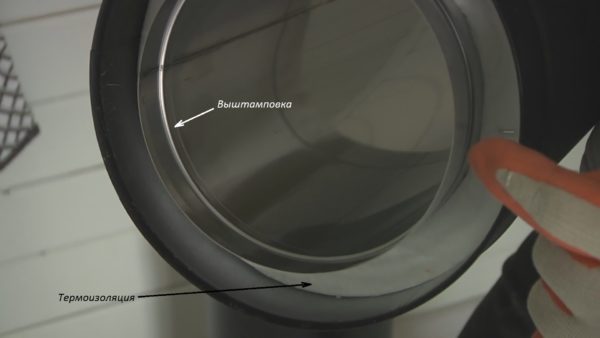

- When choosing double-circuit pipes, pay attention to the filler - it is desirable that it be white, as in the photo. This is a silicate thermal insulation that can withstand temperatures above + 1000 ° C;

- In addition, pay attention to the materials from which the inner contour is made. Aggressive condensate is in direct contact with the internal circuit, so this part of the sandwich chimney must be made of high-quality stainless steel;

- One more thing - make sure that the inner contour is stamped around the entire perimeter of the circle. Such a stamping will tightly wrap around the inner contour of the adjacent part and prevent condensate from entering the thermal insulation;

- You probably noticed that in both the first and second instructions I talked about the installation of dual-circuit systems. This is not surprising, since a single-circuit pipe is potentially dangerous and short-lived.

The choice of a conventional single-circuit chimney can only be justified by its price. At the same time, double-circuit sandwich chimneys have practically no drawbacks, except for a higher cost; - I didn’t specifically talk about brick chimneys, since their construction cannot be considered in isolation from the instructions for building a brick oven.

Conclusion

From the article you learned the algorithm for installing chimneys. I am sure that now you will be able to equip it yourself in your home. I recommend watching the video in this article, and if you have any questions, ask them in the comments.

Did the article help you?