Do you need to quickly and reliably close a flat roof or a roof with a minimum slope? Membrane roofing will be an excellent solution. In this review, we will figure out how to properly lay the material so that it lasts as long as possible. You need to follow a few simple guidelines in order to guarantee a good result.

Workflow organization

The installation of a membrane roof includes a number of actions, from the preparation and leveling of the base to its insulation. We will analyze all the stages and describe the simplest options, technologies that are easiest to implement for those who do not have experience in carrying out such work.

Acquisition of materials and tools and surface preparation

To begin with, you must decide on the method of gluing the canvases (if necessary). We will analyze two options: gluing with a special tape and welding using high temperature. The first option is simpler and faster, the second is stronger and more durable, the choice is yours.

The list of materials for simplicity and clarity is listed in the table.

| Material | Selection Guide |

| roofing membrane | There are three product options - PVC material, TPO membrane and EPDM membrane. The first option is the cheapest, but also the most unreliable, it is not resistant to oils and bitumen. TPO and EPDM materials are more durable, but their price is much higher. As for the laying technology, it is the same for all options, you should not worry about this aspect |

| insulation | To prevent heat loss through the roof, it must be well insulated. Typically, a layer of 10 to 20 cm is laid, depending on the type of structure and the region of work.

It is better to use mineral wool of high density or extruded polystyrene foam, and it is not necessary to look for a material of the desired thickness, you can lay it in two layers |

| Special Tape | It is necessary if you will glue the panels.High-strength options with reinforcement from 38 mm wide are used. A roll of such a tape 50 meters long will cost you from 1000 to 1500 rubles |

| Fasteners for insulation | Fungi dowels are used (if the base is concrete) or special telescopic fasteners (for corrugated roofs). Fasteners fix the insulation, ensuring the stability of the base and its immobility |

| Vapor barrier material | It fits under the insulation and protects it from moisture from the base. |

From the tool we need the following:

- Construction knife for cutting material;

- Welding machine, if soldering will be performed. It is best to rent equipment. Also, you may additionally need a building hair dryer to work in hard-to-reach places and glue the flaws that were made during work.

First of all, you need to prepare the surface.

The process consists of the following steps:

- The roof is cleared of everything superfluous. If there are remnants of the old coating on it, then it is advisable to remove them. If the old coating is strong and even, then it can be left. You should have a flat, dry plane, just such a base is optimal;

- Flatness is checked and alignment is performed. Everything is very simple here: first, deviations from the plane are checked using a level, if they are more than 1 centimeter per meter, then it is better to level the surface.

On concrete slabs, leveling is done with cement mortar, if the surface is very uneven, then it is easier to make a continuous leveling screed;

If the surface of the plates is even, then it is enough to repair only the joints between them. The process is not difficult: you need to put a couple of bars of reinforcement to strengthen and fill all the voids with mortar to the top.

- After leveling, the solution must dry.. This takes 1-2 weeks, so the work is best done in the dry warm season.

Insulation installation

Laying thermal insulation materials is a very important part of the workflow.

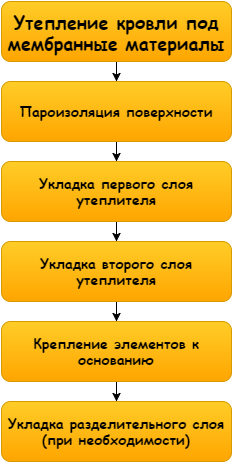

Do-it-yourself instructions look like this:

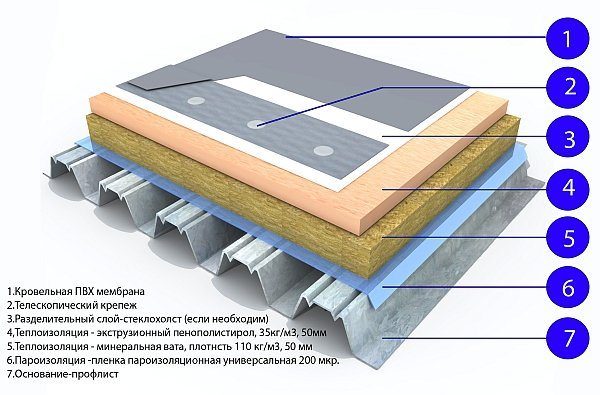

- Vapor barrier material is laid. Everything is very simple here: the film is spread over the surface with overlaps on vertical sections, if any. To ensure reliability, the joints are made with an overlap of at least 100 mm. For additional reliability, it is recommended to glue them with ordinary adhesive tape, it will fix the connection and prevent the material from moving when laying the heat-insulating material;

- The first layer of insulation is laid. I recommend using high density mineral wool with a thickness of 50 mm or more. It just folds tightly to get a smooth base without cracks and voids. It is better to cut the material with a special knife, then the pieces will be even, and you will lay the surface very high quality;

- The second layer is placed on top of the first., you can use both mineral wool and dense foam or extruded polystyrene foam.The latter option is especially good, as it has grooves at the ends, thanks to which you can combine the elements very tightly and reliably;

The most important thing to remember when laying the second layer is that the joints should never match. It is best to put elements of different sizes, then the connections will be in different places.

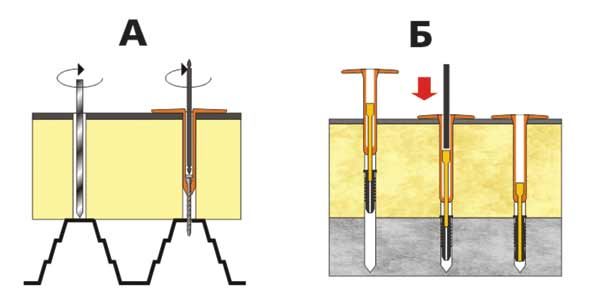

- Fastening is carried out immediately through two layers of material. If you have a concrete base, then the dowels should be 50 mm longer than the thickness of the two layers of insulation. If you have a profiled sheet roof, then special fasteners are used, which are telescopic inserts with a wide hat and a metal screw. The length of the fastening is selected based on the thickness of the insulation layer, the schemes for the work are shown below;

- If you need to strengthen the insulated surface, then geotextiles are laid. The material just spreads over the surface and is not fixed in any way. On the joints, overlaps of 10-15 cm are made.

Installation of roofing material

PVC roofing membrane is easy to install, the main thing is to have everything you need at hand.

Installation technology looks like this:

- First of all, the extreme canvas is spread. The most important thing is to align the sheet and straighten it so that there are no folds and distortions on the surface. For leveling, you can use a simple mop. Cutting the material is done with any sharp knife, it is important to do this carefully so as not to spoil the coating;

- The next panel is laid with an overlap of at least 50 mm, but it is better to make the joint even more, in the region of 100 mm.It is very important to lay out the elements evenly so that the connection is the same along the entire length;

- The surface of the membrane at the joint is cleaned of dust and debris. It is best to wipe it with a clean rag to accurately remove all excess;

- The connection of the canvases is best done with a special welding machine., which heats the surface up to 600 degrees and tightly solder the surfaces together. The work is carried out carefully and slowly, you just need to guide the device along the seam from beginning to end, it is undesirable to interrupt work halfway through;

- If gluing is performed, then the tape is first glued to the bottom. After that, the protective layer is removed and the top layer is pressed tightly.;

- All joints are checked. If necessary, individual sections are welded with a building hair dryer. PVC roofing for the best connection is pressed with a small roller;

- Elements are welded at vertical joints. In these places, the installation of a membrane roof is simple: another sheet is attached on top, which is cut to the size of the junction. The material is glued to the vertical wall with glue, and the joint is soldered, a very reliable and durable connection is obtained;

- If necessary, repair of individual sections of the seam is carried out. This type of work will be needed if, during the gluing process, you overheated certain sections, due to which the base crawled out, and it will no longer be possible to reliably make the connection.Round patches are made, which should cover the damage so that there is a 50 mm joint on all sides. Gluing is simple: the piece is heated and pressed tightly.

Conclusion

I am sure that after reading this review, you will have no problem with surface preparation and paving work. Membrane roofing is very easy to use, and the video in this article will help you better understand some of the features of the work. If you have any questions - write them in the comments below.

Did the article help you?