Building a truss for a canopy with your own hands requires accurate calculations and the ability to handle a welding machine. If you make even the slightest mistake, then the structure will simply collapse as a result under the influence of snow and wind. Therefore, before starting work, read the recommendations below.

Completion of the task

Canopies have a fairly wide scope:

- The equipment of open-type car parks, which are a cheaper alternative to capital garages.

- Arrangement of public transport stops, canopies of shops and even advertising banners.

- Creation of verandahs and arbors. Another option to save money on building a full-fledged garden house is to create a reliable roof with durable racks.

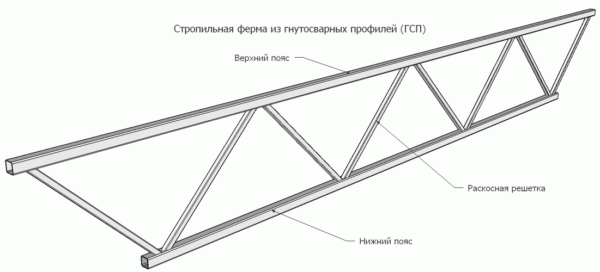

At the same time, their reliability is ensured by metal trusses, which firmly connect the logs and support pillars. Such a design, if properly installed, will serve you for a long time and with high quality. You should start with the choice of suitable materials.

What is the best way to make a farm

The best way to cope with this task is metal pipes with a rectangular or square section, which have several advantages that are important for our case:

- High strength due to the presence of stiffeners. If a round product is quite affordable to bend at home, then such a trick will not work with a profile one.

- Affordable price due to relatively simple production technology. Hot rolled specimens are best suited.

- Convenient form. Fastening flat walls with your own hands is much easier than rounded ones, this applies to both welding and bolts.

When choosing sizes, follow these rules:

| Canopy width, cm | Pipe section size, mm | Pipe wall thickness, mm |

| Up to 450 | 40 to 20 | 2 |

| 450-550 | 40 to 40 | 2 |

| Over 550 | 60 to 30 | 2 |

| 40 to 40 | 3 |

What to consider in calculations

Tip: if you have any doubts about the correctness of your calculations, it is recommended to consult a specialist, since the price of a possible error will be much higher than his paid services.

Before you calculate a farm for a canopy, get a counting machine and a specialized program that is freely available on the Internet.

The calculation of the canopy structure involves the following actions:

- Choice of truss structure scheme: arched, single-pitched, double-pitched or straight. Here you should take into account the functions performed by the future canopy, the materials used in its construction and personal preferences.

- Next, the dimensions of the entire structure are determined.. At the same time, it is important to realize that in the case of an increase in the height of the canopy, its bearing capacity also increases. Therefore, in this case, it is worth taking care of additional installation of several stiffeners, which will increase the strength of the object.

- In the case where the span exceeds 35.9 m, calculations for the building lift are required to determine what the deflection bend will be, directed back from the actions on the structure..

- The parameters of the truss panels are also determined in accordance with the distance from each other of the componentstransferring the load.

- Calculations end with finding the distance of one node from another, most often this parameter is equal to the width of the panels.

Tip: you can use old ready-made projects, just by substituting your values into them. This will greatly facilitate the task and help to avoid common mistakes.

Calculation example

For example, take a canopy with the following parameters:

| Parameter | Meaning |

| Width | 9 m |

| slope | 8 degrees |

| Span | 4.7 m |

| Estimated snow load | 84 kg/m² |

| Stand Height | 2.2 m |

One edge of the farm will be based on a brick building, and the other on a specially installed column. To create it, we take pipes with a cross section of 45 by 45 mm and a wall thickness of 4 mm.

Having carried out calculations using special programs, we will obtain the following values for the farm being created:

| Parameter | Meaning |

| Weight | 150 kg |

| Vertical load per column | 1.1 t |

| Reliability factor | 1 |

| Span | 4.7 m (coinciding with the canopy) |

| Height | 40 cm |

| Number of panels in the top chord | 7 |

Mounting Tips

It should be noted right away that welding has a number of advantages over the implementation of bolted joints:

- The absence of weighting with bolts, which allows to achieve a lower weight of the final structure and, accordingly, a lower load on the structure.

- High resistance to possible deformations. The welding seam is stronger and more reliable.

- Long service life, which is equal to the durability of the components used.

- Lower implementation cost. Electrodes are cheaper than quality bolts.

- Uniform distribution of metal. Distortion of pressure on bearing piles is excluded.

- High construction speed. A professional welder quickly copes with the task.

Tip: The only time it's better to use bolts is when you're using galvanized pipes.

Because welding destroys the zinc layer, increasing the risk of corrosion.

How to weld a farm for a canopy on your own? If you already have all the calculations ready, the material is selected, and you know how to use the welding machine, then the process will not be difficult for you.

The only thing you should pay attention to is how to cook the corners of such a structure: through one.

Conclusion

With the help of profile steel pipes, you can create reliable trusses for canopies that will serve you for a long time and with high quality. But at the same time, it is very important to correctly calculate all the parameters of the structure so that it can successfully withstand all atmospheric loads. Further, the situation is only for welding.

The video in this article will bring to your attention for consideration additional materials that are directly related to the topic presented. Get the job done right and you will be successful.

Did the article help you?