The canopy over the porch made of polycarbonate will perfectly complement and decorate your facade, as well as protect you from bad weather and objects falling from a height. We want to consider the advantages and features of such a design, as well as show the main stages that include the manufacture of canopies and visors.

Visors: varieties, features, purpose

Purpose and features

The canopy at the entrance to the house is not only protection from precipitation or falling melting snow, it is an irreplaceable architectural touch, without which the building looks unfinished. Therefore, the functions of this design are more diverse than it might seem.

Of course, the main and main function is to protect residents from bad weather, which is especially relevant at a time when hands are busy opening or closing doors and cannot hold an umbrella. In addition, it should be remembered that it is not safe to be under the wall of a high house, since a layer of melted snow with people, an icicle and various kinds of garbage can fall from above.

However, do not forget about the decorative features of this part of the facade. As a rule, the canopy complements the general architectural style of the existing ensemble, or differs from it, thereby emphasizing and emphasizing this style. To achieve this effect, you need a certain artistic taste or special knowledge.

There is also a win-win option - these are polycarbonate visors and canopies that can protect a person from the listed dangers, as well as fit into the exterior of almost any building without damaging it.

Important!

In addition to protecting a person at the entrance to the house, the visor can cover a payphone, an ATM, a balcony, a well, a shop window, an air conditioner and many other objects.

We can say that the scope of this design is simply huge.

Varieties

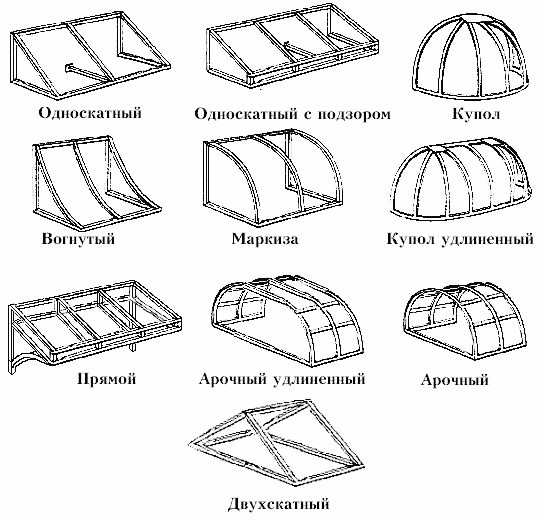

There are really many varieties of this design.They may differ in shape, method of installation and installation, materials of manufacture and purpose.

According to the shape of the product, they can be single-pitched, double-pitched, hipped, arched, have all kinds of exclusive forms. For self-production, a single-sided version is best suited, possibly in an arched version.

An equally important characteristic is the materials.

And here it is necessary to distinguish between three groups:

- Materials for the manufacture of the supporting structure. The supporting frame can be made of wood, rolled metal, steel or aluminum pipes, forged parts. The most popular are forged, welded and wooden models; (See also article Canopy from a profile pipe: features.)

- Roofing materials. There is also a huge variety here - you can find slate, metal, tile, polymer and even glass peaks and canopies. . In recent years, such material as polycarbonate has been very popular: transparent or matte, colorless or colored, strong and durable;

- Materials for fastening and fixing parts. Depending on the design chosen, special fasteners may be required: anchors, brackets, press washers, etc.

Important!

Polycarbonate retains all its advantages only with proper installation.

Most often, recently, ready-made sets of brackets and fasteners have been purchased, to which polycarbonate sheets are selected, since the price of such sets is not so high as to master welding on their own. (See also article Country awnings: features.)

Then the brackets are mounted on the wall, according to the instructions, polycarbonate is cut and fixed, and the work is completed by installing additional elements - final profiles and various kinds of plugs.

Installation

Now we will tell you how to hang a canopy over the porch with your own hands.

To do this, we have compiled a step-by-step instruction:

- We purchase a kit for assembling a frame for a polycarbonate canopy. According to the instructions, we assemble the frame from parts or modules;

- According to the measured distances, we cut the filler (polycarbonate) and insert it into the mounting grooves on the product arches;

- We press the filler with clamping bars made of aluminum or plastic, which depends on the manufacturer and the set you have chosen;

- We apply the product to the wall in the installation position and mark the upper hole for the fixing anchors. We drill a hole and mount the structure on one anchor;

- Align the canopy with a level and fasten it to the second anchor. Then we fix it completely with the rest of the bolts;

- We mount additional elements - end caps, caps for hats, overflows.

Important!

Polycarbonate should be cut with an electric jigsaw or a hacksaw, it should not be bent once again, and it is also important to ensure that during installation between the sheets and fasteners there are gaps of 1–2 mm for thermal expansion.

Conclusion

You can make a canopy yourself if you know how to weld and you have a pipe bender.You can also purchase a kit and assemble the frame yourself, insert the filler and mount the entire structure on the wall. The video in this article will help you not to make mistakes while working.

Did the article help you?