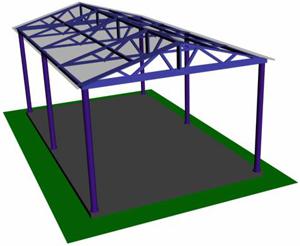

The theme of arranging a canopy in a private house or in the country has always been, is and will be relevant. Of course, you can hire people, but the installation instructions are so accessible that in the vast majority of cases a good owner prefers to do this work with his own hands. Practice has shown that a metal profile pipe is one of the most suitable materials for this.

Material advantages

- Geometrically correct shapes provide high structural strength. After all, even opposite walls are natural stiffeners.

- Profile structures can be either straight or curved.. This makes it possible to assemble strong, aesthetically attractive structures.

- Production of profiled welded pipe is much easier and more affordable than solid-rolled. Hence, the cost of the material and, as a result, the final price will be much lower.

- The frame of the canopy from a profile pipe, with high strength and stability, will have a relatively low weight. After all, farms are assembled from hollow material.

- Parallel perpendicular forms are much easier to connect and fasten together, both with a welding machine and with bolts..

- Such frames can be made stationary and collapsible..

- The wall thickness of the products used for the installation of intermediate trusses, as a rule, does not exceed 2 mm, this makes it possible to fix the roofing or finishing material directly on the structure using metal screws.

Tip: pipes can be galvanized, powder-coated or unpainted.

If you take pure metal and paint it yourself, then even taking into account expensive high-quality paint, savings can reach up to 30%.

Building Tips

Any construction includes a whole range of works. This is the purchase of material, the selection and preparation of a place for installation, the engineering calculation of a canopy from a profile pipe, and of course the assembly process itself.

Preparatory activities

In the case when you have several options for placing a canopy, you first need to decide on a place. Such structures are best placed on a hill or on a relatively flat surface where it is easy to equip drainage.Water will collect in the lowland, hence the additional cost of storm sewers.

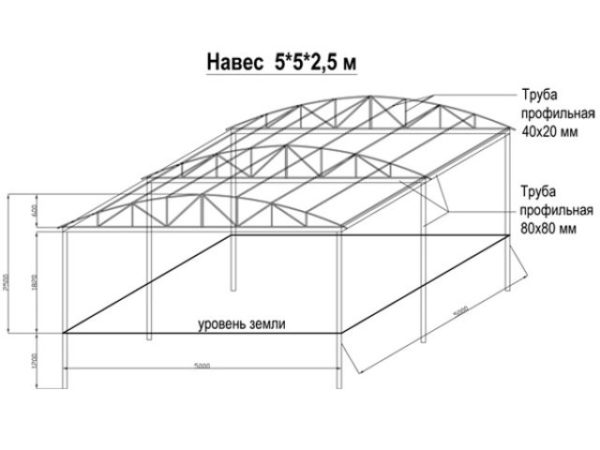

A preliminary drawing of a canopy from a profile pipe must be made. In addition to the location of the structures themselves, it is important to take into account the cross section of the pipes. So in the case when the length of the building does not exceed 4 - 6 m, and the width fluctuates around 3 - 4 m, for racks it is enough to take a pipe with a section of 60x60 mm. For a larger quadrature, a section of 80x80 mm is used.

The upper harness, on which trusses for a six-meter canopy will be based, is made from a 40x25 profile. The pipe for arches and transverse trusses is selected depending on the amount of precipitation in the area. For courtyard structures with a small quadrature, as a rule, products with a section of 30x30 mm are sufficient.

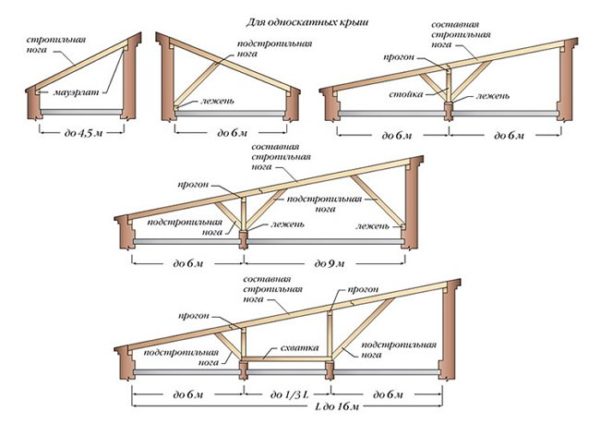

The material from which it is planned to equip the roof plays an important role here. For curved arched roofs, it is currently advisable to use light, translucent cellular polycarbonate. A direct one or gable canopy in the barbecue area is best made from a fireproof metal roofing sheet or cover with slate. Naturally, the heavier the material, the thicker the structures should be.

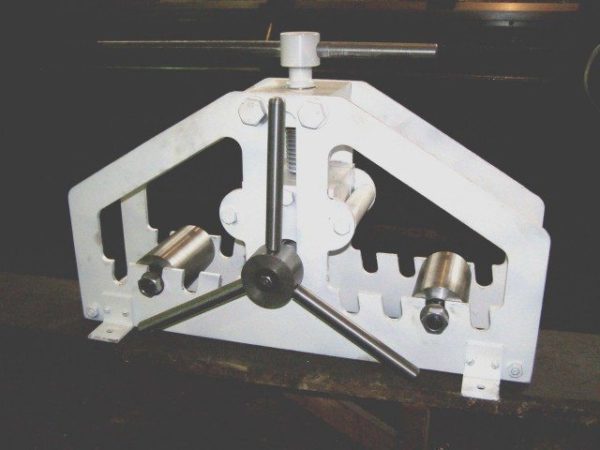

Light curved polycarbonate roof structures look attractive. Therefore, the question often arises of how to bend a profile pipe for a canopy. For this, there is a roller pipe bender, it is advisable to purchase it only for large volumes. If you are building a small canopy for yourself with your own hands, then it is better to order a service on the side.

Tip: in large hardware stores or metal warehouses, subject to the purchase of goods from them, there is a service for cutting and bending structures.

And often it can go for free, just a nice bonus.

Canopy installation

Any work of such a plan begins with the marking and installation of supporting columns. It is recommended to install supporting metal columns for light structures in the yard or in the country house in increments of about 2 m. If more spans are made, then it will be necessary to increase the cross section of pipes, the price will naturally increase.

The pits for installation are conveniently and quickly made using a garden drill with a diameter of 300 mm, a depth of 60 cm is enough. When all the pits are ready, the bottom must be well tamped in them, otherwise the column may shrink.

Before installation, a gravel or sand sole 50 mm thick is poured and compacted to the bottom, after which the column can be installed and poured with concrete. All columns are mounted strictly according to the level or using a plumb line. Such work is best done with an assistant, since there is a high probability of error alone, and when the concrete seizes, it will no longer be possible to fix it.

Concrete is poured to the level of the beginning of the pit for the arrangement of the screed. The floors under a canopy, depending on the financial capabilities and purpose of the structure, are laid out with paving slabs or a concrete screed is made.

In both cases, you will need to make a small pit. To do this, the soil is selected to a depth of 100 - 150 mm, after which the surface is leveled and compacted. If paving slabs are laid, it is recommended to cover the surface with geotextiles so that grass does not break through.

To equip the sole, you can use sand or gravel. Backfilling is done at a level of 50 mm and is also compacted. This layer is necessary to ensure normal drainage.

Next, the reinforcing cage is laid and a layer of concrete 50 mm thick is poured. Such a screed can withstand a load of up to 3 tons.

On top of the columns, a strapping is made around the perimeter of the canopy. On this horizontal strapping, transverse trusses for a sloping roof will be based. For a straight single or gable roof, trusses are installed in increments of 800 mm. The installation step for a curved roof varies depending on the width of the polycarbonate sheets, but, as a rule, it is about 500 mm.

The video in this article shows some of the subtleties of installation.

Conclusion

As you can see, making a canopy with your own hands is quite realistic. In addition, a well-mounted canopy frame made of a profile pipe, with proper care, can last more than 25 years.

Did the article help you?