In matters of increasing energy saving and comfort of living in a house, roofing insulation plays an important role. In this regard, when installing new roofs or overhauling old coatings in modern construction, thermal roofing is used, a description of which you will find in this article.

In matters of increasing energy saving and comfort of living in a house, roofing insulation plays an important role. In this regard, when installing new roofs or overhauling old coatings in modern construction, thermal roofing is used, a description of which you will find in this article.

Production of thermal roofing boards

For the manufacture of plates, fine-fiber mineral wool is taken. The composition of wool includes dolomite (25%) and basalt rocks (75%). Raw materials for thermal plates are tested for radiation safety.

The quality of mineral wool provides the thermal coating with stable properties in terms of thermal conductivity, water resistance, vapor permeability and strength.Thermoplates are classified as non-explosive materials.

Application area

Thermal roofing is used on industrial and civil construction sites:

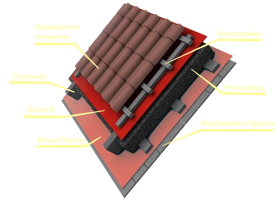

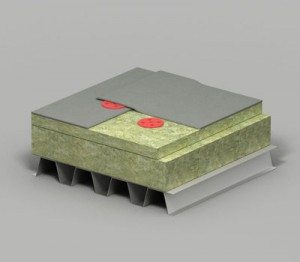

- in the form of a thermal insulation layer on flat roofs with a multi-layer roof covering made of profiled metal sheets or reinforced concrete slabs, with a mastic or rolled roofing carpet;

- as thermal insulation on roofs with a minimum slope, with a single layer coating and a cement and sand screed device.

Styling features

When using thermal roofing slabs on flat roofs, a cement-sand screed creates the necessary roof pitch.

This contributes to:

- prevent damage to the main roof coverings subject to deformation of thermal plates;

- increasing the reliability of insulated roofing;

- preventing the appearance of deflections in the metal coating.

Thermoplates on a metal coating are laid on a vapor barrier layer, which prevents steam from moving into the insulation from the room, thereby protecting the thermal roofing layer from moisture.

On a reinforced concrete base under a thermal roofing layer, it is recommended to use a vapor barrier made of roll-type bituminous deposited materials.

A vapor barrier made of bitumen-polymer materials with polyester as a reinforcing base is used on a metal profiled base.

Attention. The vapor barrier layer is laid in the roofing system on the supporting structure, directly under the thermal plates. Such laying does not depend on the type of supporting structure.

Installation

During installation, thermal roofing boards are glued pointwise to each other and glued in the same way to the base.Hot bitumen of various grades is used as a binder.

In spot sizing uniformity should be observed. In addition to bonding, the continuity of the coating is guaranteed by the ideal geometry and dimensional stability of the material.

Attention. When placing a thermal roof covering on a profiled sheet, the joints of the plates should be located on the shelves of the metal sheet.

Coating Benefits

The use of such material as thermal roofing is due to its positive properties:

- density;

- tear and compressive strength;

- low thermal conductivity;

- ease of installation;

- durability.

The use of thermal roofing boards provides, with a small thickness of the heat-insulating layer, the standard value of heat transfer resistance.

Did the article help you?