Like any other roof, seam roofing is a roof covering that protects the interior of structures and buildings from the negative effects of the external environment.

Structurally, it consists of rolled or sheet copper, galvanized steel or galvanized coated with a polymer composition. Separate elements of the roof are connected by folds, hence the name of the type of roof.

The fold itself is a type of seam connection of two sheets of metal, in which their edges seem to wrap around one another.

According to the wrapping method, the following types of folds are distinguished:

- standing single;

- recumbent single;

- double standing;

- recumbent double.

Despite the complex installation, seam roofing is the best way to connect metal roofing sheets.

Benefits of seam roofing:

- Durability (can be used up to 100 years with some types of roofing material).

- Corrosion resistance of the roofing material.

- Possibility of arbitrary choice of colors.

- Small load on the truss frame. A square meter of sheet metal weighs no more than seven kilograms.

- The smooth surface practically does not retain precipitation, which also reduces the overall weight of the roof.

Flaws:

- metal roofing is a booming resonating surface and during rain or hail it makes a fairly loud noise;

- seam roof - the installation of which was not carried out with sufficient quality, it requires a rather complicated repair;

- no matter how much you like seam roofing, it is very problematic to do it yourself, as it requires very specific skills, knowledge and tools. In the vast majority of cases, the installation of a folded roof is carried out by professionals, who at the moment are not so many in construction organizations;

- in terms of design - simple galvanized steel does not have a very aesthetic appearance

Benefits of seam roofing

Copper or zinc-titanium sheets are much more interesting for a designer, but their cost is an order of magnitude higher than galvanized steel. A square meter of the latter will cost from five dollars, and copper or zinc-titanium will cost up to $80 per square.

Working with zinc-titanium sheets is very difficult due to their insufficient resistance to mechanical damage during installation.Any scratch damages the protective coating and the sheet then undergoes premature corrosion.

Therefore, it is necessary to work with zinc-titanium sheets with a special tool; you cannot walk and knock on the sheets.

In addition, the material in question cannot be combined with a number of metals and certain types of wood, which also complicates the work. Another disadvantage is its increased brittleness at temperatures below +5 degrees - it is impossible to work with zinc-titanium in the cold.

Tip! Metal roofs attract and store atmospheric electricity. An indispensable condition for the normal functioning of seam roofs is the installation of a lightning rod.

Roofing materials for seam roofs:

- Traditionally galvanized steel. It provides corrosion resistance. A roof made of this material has been serving for three decades or more;

- Polymer coated galvanized steel. The protective layer of zinc is additionally covered from below with protective paint, and from above - with a colored polymer layer. In addition to a purely decorative function, the polymer protects the metal from ultraviolet radiation;

- Roll copper. Copper sheets often have a textured surface that mimics tiles, bricks, honeycombs, or scales. Copper can be connected not only with folds, but also with conventional soldering, which facilitates installation and increases the reliability of the roof. Copper roofs last a hundred years with minimal maintenance;

- Roll aluminum. Like copper, it can have a textured pattern. Aluminum has a low coefficient of thermal expansion and is practically not subject to thermal deformation. Aluminum roofs serve up to eighty years;

- Zinc titanium. Supplied as strips or single sheets. The disadvantages of this material have already been mentioned above.The advantages include high ductility and corrosion resistance. These roofs last up to a hundred years.

How is seam roofing installed in the 21st century?

Metal seam roofing is mounted in a couple of stages:

Stage one:

First, the ground part of the work is done. According to pre-prepared drawings, sheets and rolls of metal are cut, pictures are made for slopes, for overhangs, for gutters.

Then the cut pictures are joined by a fold into an overall picture of the length of the entire slope and the edges are bent on the sides to create standing folds.

Stage two:

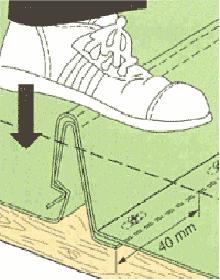

The collected paintings are lifted onto the crate, connecting them to each other. At the same time, paintings are fastened to the crate with clamps (kleimers).

The seam roof clamp is a narrow steel strip, one end of which is inserted into the standing seam, the other is screwed to the crate.

As a result of such fastening, not a single technological hole remains in the roof, which significantly increases its reliability and tightness. For additional insulation, self-adhesive tape is placed in the folds.

To your attention! Please note that all metal elements of the roof - clamps, nails, wire, bolts and other connecting parts must be made of the same material as the roof itself. Otherwise, the overall service life of the coating will be determined by the service life of the iron nail and is unlikely to exceed ten years.

All ventilation and near-pipe outlets on the roof are also covered with galvanized aprons for the same reason.Ideally, all seam roofing units should be made from the same material.

Recently, seam roofing made using roll technology is gaining popularity. metal decking on the very roof vertical stripes according to the principle - one strip from the ridge to the edge of the overhang.

This method allows you to lay the entire roof without a single horizontal seam, which greatly reduces the likelihood of leaks.

According to the roll technology, the connection is made in a double standing seam and, as a rule, the connection is additionally sealed with silicone sealant. The folded roof, the nodes of which are sealed with a sealant, requires maintenance no more than once every ten to fifteen years.

Advantages of roll technology:

- roofing sheets on the roof can have almost arbitrary length;

- a mobile rolling machine can do metal profiling immediately before laying;

- there are no transverse joints that reduce the reliability of the structure;

- the entire roof does not have a single through technological hole, which ensures high tightness.

The most popular seam roofing option is self-locking seam roofing.

When assembling such roofs, profiled steel sheets are used, perforated on one side for screwing to the crate and a curly bend that imitates an internal fold.

On the other hand, there is a spring-loaded outer fold. The roof sheet is laid vertically on the crate along the slope and fastened with ordinary stainless steel screws.

Then the next sheet is snapped onto it from above. Such a self-locking seam roof is very fast and easy to assemble.

A couple more nuances

Like any other seam roof, it has some installation nuances.

Tip! In general, a seam roof can be made with any slope, but if the angle is less than 14 degrees, then the metal is laid not on the crate, but on a solid base.

The use of silicone sealants when crimping folds significantly increases the reliability of the roof.

If you use sheets of metal longer than ten meters, then you should install the roof using floating clamps.

Seam roofing, all elements of which are made in compliance with the necessary standards, is able to reliably protect your home for many decades, without requiring frequent and complex maintenance.

Did the article help you?