The production of a roof is one of the most important stages in the construction of a house, since it is the roof that determines both its appearance and the reliability and comfort of living in it. This article will talk about the main stages of making a roof with your own hands.

The production of a roof is one of the most important stages in the construction of a house, since it is the roof that determines both its appearance and the reliability and comfort of living in it. This article will talk about the main stages of making a roof with your own hands.

Roof technology is designed to give the roof being built the following properties:

- High strength;

- Waterproof;

- Resistance to low temperatures;

- Aesthetic appearance.

In order to successfully pass the quality control of the roof, it is necessary to choose the right material for the roof and the method of its installation.

The construction of the roof includes the following steps:

- dismantling of the existing coating;

- installation or repair of the supporting structure with additional aseptic and fire-retardant treatment in the case of a rigid roof, for the installation of which roofing machines can be used;

- vapor barrier equipment;

- installation roof insulation;

- laying roofing, for which, depending on the material, roofing machines are often used;

- installation of roofing protections;

- roof painting.

Installation of a roofing pie

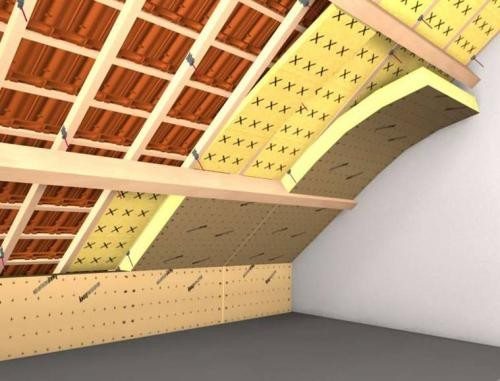

The name "roof cake" is associated with the structure of the roof, consisting of several layers that perform certain functions.

The set of layers may vary depending on the type of roof, but their order must always be observed, as well as the installation of gaps for ventilation in the roof pie.

Depending on whether the attic space will be used, the composition of the pie changes.

The attic gives off heat more intensively than the rooms below due to its larger surface of interaction with the environment.

Its effective protection is ensured by creating a continuous layer of insulation over the entire area of the roof, which will allow the roof to retain heat in winter and not let it into the premises in summer.

In addition, the roof frame must prevent the penetration of water vapor into the insulation from the inside and release moisture to the outside.

The higher the humidity of the insulating material, the lower its heat-insulating performance, therefore it is very important to ensure reliable protection of the insulation from moisture present in the air, water vapor, as well as precipitation and condensate formed on the roofing.

Control grille

After the truss structure is completed, counter-lattice bars are nailed to the rafters, the cross section of which is 50x50 mm.

At the same time, a ventilation gap of at least 50 mm should be left between the insulation and waterproofing.

This gap allows you to timely remove water vapor from the insulating material, which will prevent the accumulation of moisture in the space under the roof and allow it to "breathe". The bars of the counter-lattice should repeat the pattern of the rafters.

Waterproofing

Installation of waterproofing is carried out in the following way:

- The membrane is attached to the rafters with a counter rail;

- The waterproofing film is laid horizontally on the crate. In this case, a gap of 10 cm should be left and a slight sag, taking into account the expansion of the material under the influence of temperatures. This film will allow vapors from the interior to pass into the insulation, but retain moisture from the outside;

- If the roof slopes are located at a slight angle of 10-22º, an additional waterproofing layer is provided for laying piece materials of the roof covering. For it, rolled modified materials are used;

- In the case of using a superdiffusion membrane, it is laid directly along the rafters on top of the thermal insulation layer, after which it is nailed with counter-lattice bars.

crate

After the laying of the waterproofing is completed, the lathing is fastened across it, the pitch of which is selected depending on the material of the roof covering. The fastening of the lathing bars is carried out perpendicular to the rafters.

To carry out the crate, bars with a section of 50x50 or 40x40 mm are used, which are laid perpendicular to the rafters. This creates a second ventilation gap between the roofing material and the waterproofing, which serves to remove moisture trapped under the roof.

Important: for laying some materials (bituminous soft roofing, asbestos-cement flat slate, reeds, sheet steel and copper), installation of a continuous crate is required. In this case, the crate is made of OSB boards or moisture-resistant plywood, laid with a spread of seams.

Coating laying

The roofing material is laid directly on the crate, and it is necessary to move from top to bottom and from right to left, to facilitate the task, a roofing machine can be used.

For different materials, different methods of fastening to the crate are used:

- For shingles - nails and glue;

- For cement-sand, and ceramic tiles, as well as shingles and slates - a special lock and screws or clamps;

- For flat sheet materials, such as copper, steel, aluminum, zinc-titanium, when building a seam roof - a special lock (seam), or a roofing machine;

- For large-sized profile coatings (ondulin, corrugated board, slate and metal tiles) - helical long nails.

When laying on top of a continuous crate of soft tiles, a special lining carpet should be laid from below, leveling the roof surface and protecting it from moisture during the installation of the coating.

Fastening piece materials to the crate should be done separately.

thermal insulation

After the roof is protected from rain, it is insulated.

In this case, you should use the basic rules:

- Roof insulation it is laid as tightly as possible from the inside of the space under the roof, avoiding gaps;

- The thickness of the thermal insulation layer should not exceed the height of the rafters;

- When laying several layers of insulation, overlap should be left;

- For do-it-yourself roof insulation it is recommended to use environmentally friendly materials, such as mineral wool boards. They are distinguished by low thermal conductivity and a density of 35 kg/m3 and higher;

- Between the rafters, the insulation also fits tightly and without gaps.

Vapor barrier installation

The vapor barrier is laid inside the under-roof space along the inside of the insulating material. The vapor barrier material (polyethylene reinforced with a mesh or fabric) should be laid, observing an overlap of 10 cm.

For sealing, glue the joints with self-adhesive tape. The vapor barrier is attached to the rafters using a stapler.

Important: care must be taken to ensure that the vapor permeability of the individual layers of the roof cake increases towards the outside. This allows the roof to "breathe" and prevents the accumulation of moisture in its materials and structures.

That's all I wanted to tell you about the manufacture of the roof.It is important to remember that each stage of its construction should be carried out as efficiently and accurately as possible in order to ensure its reliability and durability.

Did the article help you?