Ondulin was invented in France in the early forties of the last century. Later, it appeared in Europe, and came to us relatively recently - less than two decades have passed since the material began to be used in our country. Ondulin - the characteristics of which we will describe below, is rightfully considered one of the best roofing materials.

The fact is that only high-quality components are used for its manufacture.

Material properties, advantages and disadvantages

Please note that the material must have a certificate of conformity.

In the production of material for ondulin roofs cellulose, special refined bitumen, resins, minerals and pigments are used.The high-pressure impregnated fibers acquire a perfect look and amazing strength.

In the production of material for ondulin roofs cellulose, special refined bitumen, resins, minerals and pigments are used.The high-pressure impregnated fibers acquire a perfect look and amazing strength.

A rich selection of colors and shades, which different types of ondulin and its analogues have, will allow you to easily choose the right coating. Coloring pigments are made on a mineral basis, therefore they are absolutely harmless.

Here are the main properties of this bituminous slate:

- Very long, in comparison with many other materials, service life. With a manufacturer's warranty of 15 years, however, in fact, it can last up to 50 years.

- Thanks to the natural ingredients used in its production, ondulin absolutely clean environmentally. It is harmless to both humans and the environment. But at this point, ondulin has pros and cons, where the positive side can be considered the absence of asbestos in the composition. The minus can be attributed to a small characteristic smell of bitumen, which appears during intense heat.

- Endurance and strength. The mass of snow is maintained easily. However, in very severe frosts, the material becomes more brittle. Therefore, ondulin - we voiced its shortcomings at low temperatures, it is recommended to lay it on a slightly more frequent crate than ordinary slate.

- Fire safety andulin roofing. The material has the corresponding certificate, however, in the range of fire-resistant coatings it is not in the very first row. When heated from 250° to 300° ondulin may ignite. Despite these shortcomings, ondulin can be used almost everywhere.

Note! However, when covering social buildings with it, nevertheless, it is worth being extremely careful. Therefore, when building kindergartens, schools, shops, clubs and other things, the developer will rightly be subject to increased requirements.It will be necessary not only to strictly observe fire safety, but also to divide the coating during installation with special separators into autonomous segments. They will allow, in case of fire, to localize and eliminate it in time.

- Light weight and easy installation. This is an important fact, since both transportation and installation cost both money and nerves. In this case, you will save both. The fact is that the properties of ondulin are such that you will deliver it without problems, and installation will be quick and hassle-free.

- Various color solutions. Since the material itself consists of natural components, its coloring is made in the same traditions. Pigments on a natural basis will not make you doubt the safety of the material. And as we know, everything natural is not only safe, but also durable. And, if we analyze in detail the technical characteristics - ondulin for surface finishing is one of the highest steps. The ability to choose the right color harmony with the structure makes ondulin even more popular.

- Increased moisture and heat insulation, as well as protection from extraneous noise. This ondulin has minor disadvantages compared to the advantages. And the listed properties are in the first row of the advantages of the material. They will make the roof the perfect protection for your home.

As you understand, the material is not in vain so popular among consumers and builders. Each coating, despite its quality, necessarily has objective positive and negative sides.

If we consider the pros and cons of ondulin, then the former will clearly prevail over the latter.

Let's take a closer look at sheet formats and their technical properties.

Technical data

Today, when the products of leading foreign companies have appeared on our market, there is a need to learn more about them in order to decide which of the proposed ones to give preference.

Now we will talk about what technical characteristics Ondulin has. It is desirable to know them for those who are building their own house, cottage or commercial building.

The first thing you should pay attention to is the composition of the product. It consists of the following components:

- bitumen cleaned in a special way;

- mineral fillers;

- cellulose fibers (base);

- polymer resin (impregnation);

- mineral pigments (surface coloring).

Note! If ondulin - the properties that the manufacturer is touting, does not contain all of the above components according to the documents - you are offered a cheap fake.

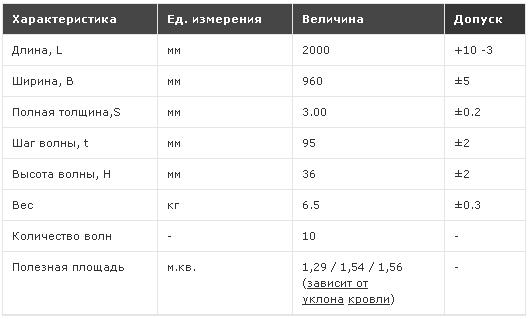

Next, we describe the standard sizes of cover sheets for roofing.

- Sheet length - 2.00 m.

- Sheet width - 95cm.

- Sheet thickness - 3.0mm.

- The height of the corrugation is 36mm.

- Sheet weight - 6.0 kg.

It is worth noting that in order to use this particular material, a crate with a more frequent step is desirable for you. As mentioned above, the disadvantages of ondulin include increased sensitivity to very sharp temperature changes.

In other words: bituminous slate softens at high temperatures, and becomes brittle at too low.

In our regions, it is not so often too hot summer, so the use of ondulin will not lead to problems. A layer of snow cover with a thickness of a meter or more, the coating withstands completely without loss of its qualities and easily.

The material also tolerates temperatures down to -25° in winter without losing its properties.

Of course, the advantages of ondulin were discovered, first of all, by European users. The fact that by the 1950s many homeowners in Europe recognized and appreciated this material speaks volumes.

Styling features

Installation of bituminous slate practically does not differ from laying a conventional asbestos-cement analogue on the roof. The corrugated surface gives both a noise-absorbing effect and provides all the insulating properties for decades, without loss of quality.

It is attached to the rafter system using a conventional drill and nails, or self-tapping screws. Holes are drilled with a drill, then a roofing screw is screwed in, as in the usual case with roofing materials.

It should be noted that nails or screws must be equipped with seals that prevent water from penetrating under the coating.

Despite the individual disadvantages of ondulin, this material will serve you many times longer than its counterparts. This is not the cheapest, but one of the highest quality and prestigious coatings, both in appearance and in all characteristics.

Did the article help you?