A strong, lightweight and durable bitumen-polymer-based material - ondulin, will last a very long time and create reliable protection for the house if you perform the installation correctly. It is possible to lay it on roofs of any type - from the simplest to the most complex. Natural components in the composition are completely harmless to health and the environment. Having learned a little more about how to lay ondulin, you can easily and quickly cope with the task yourself.

Since ondulin is a very durable and lightweight material (the weight of the sheet is only about 6 kg), transportation and installation is extremely easy. You can not be afraid that the sheets will be scratched or broken from accidental impacts.

Characteristics of ondulin

Many are interested in the question - what does ondulin look like, and what is included in its composition. And it is produced by the French company of the same name from cellulose impregnated with polymeric substances and then coated with distilled bitumen. Special technologies for its manufacture make the material very durable and resistant to various damages. Sheets with dimensions of 200 cm × 95 cm have a wavy surface, which gives them increased rigidity. The mass of one sheet is 6 kg, the height of the ondulin wave is 36 mm.

Note!

The profile in the form of waves not only allows water to drain quickly and evenly, but also dampens the noise from falling drops during rain.

The sheets are painted in a variety of colors, so choosing the shade you need will not be a problem.

The material is very similar to ordinary asbestos-cement slate, with the only caveat - it looks more aesthetically pleasing.

Consider when laying ondulin not only air temperature and weather conditions. The material must not be installed at a temperature of -5°. Despite its light weight, ondulin is a very durable material. However, at high temperatures, the bitumen included in its composition softens, bringing the material into a rather plastic state. At very low temperatures, on the contrary, ondulin becomes more fragile. This should be taken into account when stepping extremely carefully on the roof during installation work.

Separately, it must be said about such roofing as PVC Ondulin 95. It is produced in two varieties: transparent for maximum penetration of sunlight, and also translucent - for subdued natural light.With the same size and profile as bituminous sheets, the PVC equivalent is an easy and economical way to get daylight through the roof.

Ondulin transparent and translucent resistant to ultraviolet radiation, while remaining extremely reliable and safe. Thanks to the latest technologies for protecting the material on both sides, its quality remains unchanged during operation. Sheets perfectly resist deformations under the action of high temperatures, since they do not create internal pressure.

Materials similar to ondulin

Concerning bituminous slate French company, then, due to its popularity, over time it acquired many clones. Roof coverings that have almost the same properties as ondulin are brands such as Nuline, Gutta, Ondura, Aqualine, Bitinvell, etc. All ondulin analogues are mounted according to similar schemes, have the same operating conditions and can be laid on top of the old roofing.

Nuline slate is a product of the American company of the same name. This is a corrugated roofing sheet produced by pressing from hardwood cellulose fibers and impregnated with high pressure refined bitumen. The outer surface of the slate has a patented swollen coating, which is coated with a two-layer painting.

The dimensions of the material are 2 × 1.22 m, its thickness is 3 mm, and the wave height is 35 mm. One sheet weighs about 8kg.

The front side of the bituminous slate Nulin can be shiny or matte. It is produced in several colors: blue, green, red, white, gray and brown.

Ondura is a corrugated sheet produced by impregnating organic fibers with refined bitumen at high temperatures and pressures. This roofing material is produced by the same manufacturer as Ondulin slate. The cover comes with a 15 year guarantee.

Sheets can be painted in green, red, brown, burgundy or blue. Their sheet dimensions are 2 m × 1.045 m, the thickness is 2.6 mm, the height of the waves is 35 mm. The weight of one sheet of this bituminous slate is 6.4 kg.

Another analogue of ondulin, the Bituwell brand, is bituminous corrugated sheets and is produced by the German company of the same name. The material is dyed in red, green, brown and burgundy. They can have both matte and shiny surfaces. The dimensions of the material are 2m × 0.93m, its thickness is 2.8 mm, the height of the waves is 36 mm. One sheet weighs 5.8 kg.

Aqualine is a roofing sheet produced from cellulose fibers and quality bitumen by the Belgian company ASBO. This slate has a glossy surface and is painted in green, red or brown. Warranty period - 10 years.

The dimensions of the material are 2×0.93m, their thickness is 3 mm, the height of the waves is 35 mm. Weight of one sheet -5.6kg

For those who have chosen bituminous slate for themselves, it will be useful and interesting to learn how to put ondulin on the roof. Observing the technology, almost everyone can perform independent installation.

Technology and installation procedure

Upon purchasing the material, you will find detailed instructions for use attached to it.However, it does not hurt to find out about this in advance so that there is time to think through all the nuances and take into account possible problems.

Note!

A person who is at least a little familiar with how to properly lay ondulin will first of all advise you to determine the exact angle of the slopes of your roof.

This is a mandatory item, based on which the distance between the crate step and the size of the sheets overlapping each other is determined.

Having learned this angle, proceed as follows:

- When the slope is from 5° to 10°, it is recommended to make a continuous crate. The size of the transverse overlap is 30 cm, the side overlap is two waves.

- When the slope is tilted from 10 ° to 17 °, a crate is made in increments of 45 cm. The transverse overlap will be 20 cm, the lateral one is equal to one wave.

- When the slope is from 15 ° to 30 °, the crate is performed in increments of 61 cm, the transverse overlap is 17 cm, and the side overlap is one wave.

Since the weight of the ondulin is small, there is no need to make additional reinforcement of the truss system. But, it should be noted that at high temperatures the material softens slightly and may bend. Therefore, too rare a crate step is undesirable..

The order of further work looks like this:

- The crate beam is nailed to the rafter system with a step corresponding to the slope angle of the slope. To control the parallelism of the bars, it is convenient to use a piece of the bar, inserting it between each previous and each following bar of the crate.

- If necessary, before putting ondulin, you can cut the sheets into fragments of the desired size. This is done with a regular wood saw, although a circular saw can also be used. To make the saw work easily, it is advisable to lubricate it with any oil.

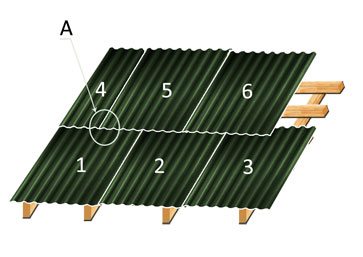

- It is advisable, before correctly laying the ondulin, to begin installation by laying the first sheet from the edge opposite to the direction of the wind. In even rows, it is advisable to start by laying half the sheet.

- After pre-laying and leveling, ondulin can be nailed to the crate. Best of all, special nails designed specifically for this material are suitable for this. Each nail is equipped with a wide head and a gasket that ensures tightness. Nails will be required at the rate of 20 pieces per sheet. In order for them to enter the crate in a straight line, it is convenient to stretch the cord and hammer them along its line.

- Nails are driven in at the highest point of each wave. Ondulin is attached along the transverse edges for each wave, in the middle - through one. Before working with ondulin, holders for gutters are attached along the perimeter of the roof.

- After the sheets are nailed, gutters are attached to the cornice board. To prevent water from overflowing over the gutter, take into account when laying the ondulin so that the sheet is no more than 5-7 cm at the level of the gutter.

- To additionally isolate the cornice from water, it is recommended to use a special box for cornices. Sheets should also be on it, no more than 7 cm.

- For ventilation and to prevent the entry of birds, insects and other animals, a special comb is installed under the eaves.

- For non-ventilated cornices, it is possible to use filler for onduline roofs.

- Ridge protection is installed and nailed to each wave of the coating, under which additional crate battens are placed. The overlap of the ridge protection on the sheets must be at least 12 cm.

- Anyone who already knows how to properly cover with ondulin will take into account that the roof chip must be protected with a special chip element.There is another way - the edge of the coating sheet is folded onto a chipboard and nailed at intervals of 20-30 cm. But this method will work only if it is warm outside. Ondulin is quite plastic in heat and brittle in the cold.

- In places where the roof adjoins the wall, as well as where a chimney, windows or other elements exit, sealing aprons designed for this material must be made out.

- All joints must be additionally insulated with a special tape or sealant.

- If it is necessary to get daylight under the roof, a special, translucent ondulin, which was described above, is mounted in the right places.

- To ventilate the roof, you can attach a special fan. The roofing device is nailed to each wave. Make sure that the top sheet overlaps the base of the instrument.

- They make an additional crate and fix the valleys.

- If necessary, lay the ondulin on a rigid base (concrete, slabs), it is possible to fix the crate directly on the base. Next, the coating is laid exactly as described above.

Did the article help you?