Slate is a well-known material that has been widely used in construction for a long time. This article will discuss the fastening of slate: what tools and equipment are used for this and how to fasten for different types of material.

Despite the wide variety of modern building materials that have appeared recently, slate is still quite popular and questions about how its installation is carried out, in particular, how to properly nail slate, are quite relevant.

For the manufacture of slate, a mixture of asbestos and cement is used, some sheets are additionally reinforced with a metal mesh. In addition, in some cases, sheets are stained.Answering the question of how to properly fix the slate, we can draw an analogy with metal tile, since in both cases it is fastened to the crate.

Talking about how to nail slate, it should be said that special nails are produced for slate, the main difference of which is to work on a cut, that is, it allows you to securely fix the sheets in one place, preventing them from shifting or deformation during operation.

To fasten the grooves, galvanized steel strips are used, and the joints at the junction of the roof to the walls are closed with special aprons, at the ends of which semicircular buttons or screws are attached, or both, if necessary. On top of the ridge beam, slate grooved skates are laid, fixed with anti-wind brackets and nails.

How to fix slate

Increasing productivity is a pressing issue even for construction professionals. The constant improvement of technology and the release of new materials lead, for example, to the replacement of a hammer and nails with electric screwdrivers and self-tapping screws. In this regard, the problem of choice arises: how to nail the slate and whether it is worth nailing it or using another type of fastener.

It would seem that such trifles should be given due attention, otherwise repairs may be required already at the initial stages of operation, as a result of which the time saved during construction will turn into much higher costs during repairs. Therefore, even at the design stage, you should figure out how to fix the slate so that its attachment to the crate is reliable and durable.Consider the main methods of fastening this material.

Nails for slate. The length of the nail used when nailing slate sheets to the crate is from 7 to 12 centimeters. In order to additionally fix the sheet, the diameter of the nail head is increased to 14 millimeters, and non-corrosive materials are used for its manufacture, for example, galvanized steel.

Useful: The most effective choice on how to properly nail slate are nails that are fully galvanized.

The size of nails for slate is selected in accordance with the height of the ridges of the sheet, guided by a fairly simple rule: the larger the ridge, the larger the nail itself. It is recommended to choose nails so that their length is 10 mm higher than the total height of the crest of the slate sheet and the thickness of the board used in the crate. Such a margin allows you to bend the ends of the nails, providing additional fastening strength and resistance to strong gusts of wind that open the roof.

Ordinary nails are driven into the crests of a wave of hard slate sheets, and soft rubber nails into their grooves. When driving nails, it is necessary to carefully monitor that rainwater does not penetrate the nails onto the crate. For this purpose, when driving in nails, it is recommended to use rubber gaskets.

The application of corner notches on the surface of the nails allows you to get ruffed nails for slate, the connection with which is particularly reliable. It is almost impossible to pull out such nails, most often they simply break.

A normal hammer is used to drive nails.In the case of making crates from hardwood, it becomes necessary to use pliers to hold nails in the process of driving them in. In order to avoid splitting a wavy roof, only nails of its level should be hammered.

The use of slate will continue to be popular until asbestos cement slate production ceases. For fastening materials such as metal profiled sheets and metal tiles, special roofing screws are used in a wide range of construction markets.

Self-tapping screws for roofing began to be used in the construction of slate roofs not so long ago.

These self-tapping screws are made specifically for fastening roofing materials and have the following advantages:

- During production, they are hardened, which makes the self-tapping screws much stronger than ordinary nails;

- Currently, roofing screws of various lengths are produced, as well as in various versions, which greatly facilitates the selection procedure for the developer;

- Self-tapping screws with a variety of head colors are available on the market, which allows you to choose the right option for any color of the roof.

Manufacturers produce self-tapping screws with various heads, under which there are already gaskets.

There are three types of screw heads:

- under the wrench;

- under a Phillips screwdriver;

- with a flat screwdriver.

Helpful: Screwing in roofing screws can be accelerated and facilitated by using power tools.

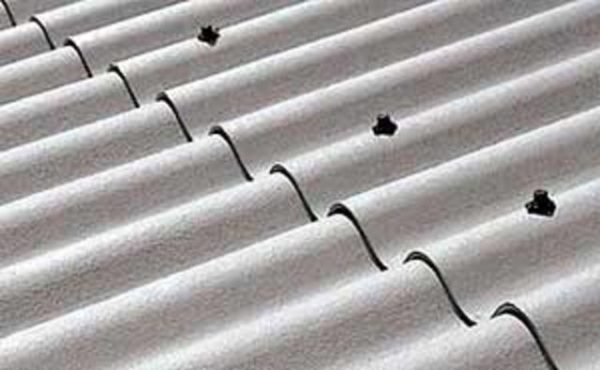

Corrugated slate fixing

The corrugated slate is fastened with nails or self-tapping screws.Sometimes (on overhangs) anti-wind brackets are also used, the step of which is 1-1.5 m.

Consider the main nuances of fastening wave slate:

- For fastening the gable and cornice rows on one sheet, two nails or screws are used, and for standard rows - one at a time;

- Fastening holes are drilled after the laying of adjacent sheets is completed;

- An anti-corrosion protective coating is applied to the protruding heads of self-tapping screws or nails, such as drying oil, varnish, paint or epoxy;

- Gaps and cracks at the junction points of the sheets can cause the roofing of wave slate to be vulnerable, so it is recommended to cover them with ready-made foams and sealants;

Useful: cold mastic Mikhailevsky is also suitable for filling cracks or gaps between sheets, which is applied in a layer with a thickness of 5-6 mm.

The layer width is 30-40 mm for transverse joints and 60-70 mm for longitudinal ones.

- Sheets are fed to the roof in case of a large number of them using a crane, and at the place of work the material is laid out for convenience by wagons, each of which has 6-8 sheets;

- Laying slate is done while kneeling or sitting on the crate.

Let us consider in more detail the process of fastening sheets of corrugated slate on the roof:

- Covering roof ridge, first of all, they put a bar on the rafters, the cross section of which is 90x70 mm. On both sides of the bar, two batten beams are installed;

- A ridge beam with a rounded upper border and brackets for hanging running bridges are attached to the central beam;

- The ridge beam is upholstered around the entire perimeter with roofing material 350 mm wide, after which the skates are laid on top of it.

- The ridge covering is formed by two skates laid on adjacent slopes: first, a skate is attached, the length of which is increased by 10 mm, then a shorter skate. Both skates should be laid so that their expanded ends are directed towards the pediment;

- On both skates, holes are drilled for fastening: two holes each on flat lapels, and two more each on the longitudinal axes of the humps. In this case, it is necessary to ensure that the holes located on the lapels pass in the crests of the waves that make up the main covering of the sheets.

Flat slate fixing

Flat slate has the following main advantages:

- Increased strength, due to which the material is practically not damaged even while people are walking on it;

- Long service life provided by factors such as low heating under the action of sunlight and unaffected by adverse weather conditions;

- Low noise effect. Certain properties of flat slate make it possible to make loud sounds coming from the street almost inaudible;

- Fire resistance, which is one of the most important advantages, since it provides high fire safety.

Important: it must be remembered that with all its positive characteristics, flat slate contains asbestos, which has a negative effect on the mucous membranes, respiratory tract and human organs of vision.

However, fastening a flat slate is a fairly simple and safe procedure for health, during which several nuances should be taken into account:

- First of all, it is necessary to apply a special priming penetrating composition that protects the roof from the reproduction of mosses.

- It is also important to carefully select the size and number of slate sheets before proceeding with the installation. At the same time, it should be remembered that holes will be drilled in the sheets, the diameter of which is 2 mm larger than the diameter of the nails, and when laying the sheets, an overlap should be left that is one wave horizontally and 10-15 cm vertically.

- Before fixing flat slate, it is necessary to equip steam and waterproofing roofs.

Fastening both flat and wavy slate is not difficult; a person who does not have special skills is quite capable of handling this work. Compliance with the fastening rules will allow the roof covered with this material to serve for a long time and efficiently.

Did the article help you?