The crate under the metal tile serves as the direct basis for this material. And since there are a lot of subtleties and nuances with its device, it is advisable to entrust its installation to professional installers. Before laying the roof covering, care must be taken to create optimal conditions for a reliable and durable flooring.

The crate under the metal tile serves as the direct basis for this material. And since there are a lot of subtleties and nuances with its device, it is advisable to entrust its installation to professional installers. Before laying the roof covering, care must be taken to create optimal conditions for a reliable and durable flooring.

And how this can be achieved, we will try to convey to you in this article.

Rules for the installation of lathing for metal tiles

Before you properly make a crate for a metal tile, you should study in detail the postulates of arranging the crate, since each type of roof will require stuffing the crate with a different pitch.

Typically, boards counter battens for metal roofing have different thickness.For example, when buying boards for a crate 30 mm thick, in fact, elements will be obtained whose width will fluctuate relative to the declared one within plus or minus 5 mm.

A similar phenomenon can be observed almost always. An exception, perhaps, can only be considered a calibrated planed board. Therefore, when preparing to install the crate under the metal tile, you should first calibrate the boards.

This procedure is necessary so that at the joints or adjacent rows of lathing boards that differ significantly in thickness do not come across, since their installation will lead to differences that will prevent the laying of metal tiles.

A board 30mm thick is needed for stock, as sawmill tolerances can significantly reduce its thickness. And due to the fact that it is planned to walk on this board in the future, it is necessary that it can withstand the weight of a large person.

Advice! It is not recommended to use a semi-edged or unedged board when installing a crate under a metal tile.

The calculation of the step of the boards of the batten for the coating of metal tiles is carried out according to the following rules:

- The step of the crate for the metal tile is selected in accordance with the type of metal tile, because different steps are required for different profiles.

- The distance between the lathing bars is usually indicated in the instructions for a particular type of roof, it is considered from the bottom of the first board to the top of the second.

- The step value between the first two boards of the crate should be smaller.

- In addition, both the slope of the roof slope and the amount of protrusion of the roofing material beyond the first bar of the batten can affect the step of the crate for metal tiles.

- The calculation of the crate step, among other things, can be affected by the absence or presence of a drain, which can also have a different configuration. When attaching the gutter to the frontal board, it will add an additional 30mm to the protrusion. Among other things, the diameter of the gutter plays an important role: with a gutter of 90 mm in diameter, a protrusion of one size will be required, with a 120 mm in diameter, a completely different one.

- The protrusion of the material for the roof is counted from the frontal board, if it is absent, from the rafter cut. The steeper the slope of the roof slope, the lower the metal will need to be lowered in order to achieve the required protrusion length. An incorrect calculation can lead to the fact that for a metal tile, the crate will not be located where it is necessary to fasten the metal tile with self-tapping screws.

- To correctly calculate the distance between the first and second board, you need to lay a level of 120-150 cm long on the rafter, then measure the distance from the top of the first wave to the bottom of the metal sheet, and then make a mark.

- Then it is necessary to extend the level like a roofing sheet, then attach the square to the frontal board and set aside the point of the required protrusion on it, and then bring the level to this point. From the edge of the frontal board, draw a vertical line to the established level and make a mark. Between both marks made, a certain distance will remain between the top of the second and the bottom of the first board of the crate, taking into account the slope of the slope and the protrusion of the roofing material.

- The very first board must be made thicker than the others in order to avoid getting a hanging protrusion when fixing the roofing material.

- The rest of the batten boards roofing measured from the top point of the second board at regular intervals in accordance with the roof profile. Sheathing marks should be applied every two rafters, as the board may eventually turn out to be crooked, and it will need to be stretched along the marked marks.

- Upon completion of the installation of 3-4 rows of the crate system, the remaining boards can be laid on the slope and then take the elements from the slope. This will provide some convenience.

- In one row of boards, the battens must be connected on the rafters. Do not lay the base boards under the roofing material with an overlap, as, for example, when laying slate. In addition, the joints will need to be spaced along the rafters. It is not recommended to join the entire crate on one rafter, otherwise the design will not provide sufficient rigidity.

Advice! In the presence of valleys, the calculation and laying of the lathing is carried out from top to bottom, and the duration of the tail of the roofing material should be taken into account. In rare cases, the presence of a long tail will require the installation of an additional board to ensure the rigidity of the fastening of the skate bar.

Instructions for installing the crate under the metal tile

Now we present a step-by-step instruction on how to make a crate for a metal tile:

- A beam for rafters is usually selected with a size of at least 50 * 150 mm, and boards with a section of at least 25 * 100 mm are used under the crate. A board 25 * 50 mm is suitable for making a counter-lattice.

- The pitch of the rafters for laying such a crate is performed within 600-900 mm.

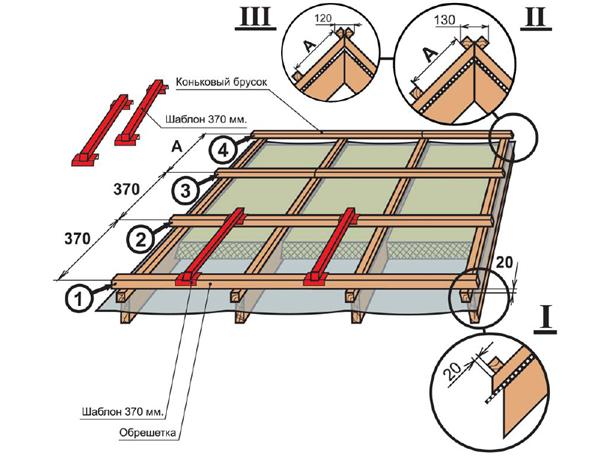

- The initial board is nailed strictly along the cornice overhang so that it does not protrude beyond it, clearly in a straight line.The thickness of the first board is made 10-15 mm larger than the rest, which is required to compensate for the difference in the levels of the support points of the first and subsequent tile modules.

- The pitch of the metal tile sheathing assumes such that the distance from the board that goes to the cornice is 50 mm less than between all subsequent ones - 300 or 400 mm. The step between the remaining boards of the crate is made equal to the step of the profile of the laid metal tile, that is, 350 or 450 mm.

- To check the correct distance from the first to the second board of the crate, two plank trimmings are laid out on the ground in a position parallel to each other and at a certain distance (or they are baited directly on the crate), after which a tile element is applied to them and thus it is determined whether protrusion of tiles to ensure normal water flow. A protrusion that is larger than allowed can lead to overflows of water through the gutter, while too little will lead to water blowing between the gutter and the frontal board. In addition, there is a possibility of deformation of the sheets under excessive snow load.

- All markings are done using a tape measure, starting from the first board that goes to the eaves.

- Next, perform the fastening of the end and ridge trims.

- The wind board is arranged above the crate to the height of the metal tile sheet. The height of the sheet, depending on the type of tile, ranges from 35 to 55 mm.

- For reliable fastening of the ridge, additional boards of 25 * 100 mm are nailed at the points of its attachment, which is required to simplify its further installation.

When planning an organized drain from the roof, before installing the roofing, it will be necessary to install brackets for attaching gutters.The cornice strip is also mounted before installing the metal tile along the roof overhang.

At the beginning, the places of attachment of the brackets are determined. They are installed in increments of 500-600 mm relative to each other and fixed to the bottom board of the crate.

First, the extreme brackets are mounted so that the slope of the gutter is 5 mm per 1 m of length, after which the cord is pulled to evenly install the remaining brackets.

The gutter is inserted and fixed on the brackets, the cornice strip is attached to the crate in such a way that the edge of the gutter overlaps with the lower edge of the strip. This will ensure that condensate drains into the gutter from the bar. The length of the overlap of the eaves strips must be at least 100 mm.

A properly arranged crate for metal tiles will allow you to lay the roofing without any extra effort and provide reliable protection against moisture.

Did the article help you?