To date, one of the very popular finishing materials is corrugated board. Metal wall corrugated board is very strong, reliable, durable, aesthetically attractive. Lightweight and easy to transport and install, the sheets are used not only for finishing walls inside and out. Fences and gates, ceilings, roof protection, fences and much more - this is the scope of its application.

To date, one of the very popular finishing materials is corrugated board. Metal wall corrugated board is very strong, reliable, durable, aesthetically attractive. Lightweight and easy to transport and install, the sheets are used not only for finishing walls inside and out. Fences and gates, ceilings, roof protection, fences and much more - this is the scope of its application.

What is profiled flooring

Thin galvanized steel, in some cases covered with an additional layer of polymer in various colors. Sheets are profiled to give them additional strength.

Thus, an original, very durable material is obtained that can last at least 50 years.The corrugated surface also serves decorative purposes.

Therefore, wall corrugated board not only protects the walls, but also gives them additional attractiveness and a noble appearance.

The material is used not only for private construction, for example, roof installation, it is often used for finishing large industrial enterprises, warehouses, workshops and other things.

This is not surprising, because not every material has so many advantages. Among them are strength, fire resistance, resistance to moisture, high and low temperatures, mechanical stress, ultraviolet. In addition to everything - excellent decorative properties.

Technical characteristics of the metal profile

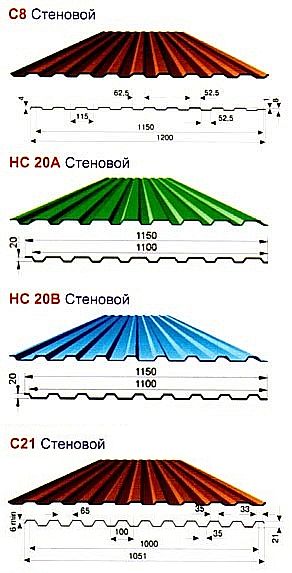

For various purposes and types of finishes, material with different characteristics is produced. The height of the corrugation and the shape of the profile, the thickness and size of the sheets are different.

Note! There are two main types of this material, they differ in their purpose. That is - for interior decoration and for exterior. Interior decoration is carried out using thinner and more elegant sheets, more powerful elements are used to protect buildings from the outside, as well as to design fences or gates.

Typically, corrugated walls have a corrugation up to 35mm high. The corrugation is round, rectangular or trapezoidal in shape, with different pitches.

Naturally, the higher the corrugation and the thicker the sheet, the greater the strength it acquires. For wall decoration, material with grades is intended: C8, C10, C20 and C21. The number in this case indicates the height of the corrugation.

As a rule, for interior and exterior wall decoration use production of corrugated board grades C8 and C10.For the manufacture of fences, fences, ceilings, gates and other things, it is desirable to use grades C20 and C21, where the corrugation is higher and, accordingly, the strength of the sheets is higher.

The material has a mass of 5 to 8 kg per square meter, sheets are produced with a thickness of 0.4 mm to 0.7 mm. Thickness profile for corrugated board are selected in the same way as the brand - according to the future load.

As for the color scheme, it also differs by brand. The main ones are considered to be: RR42, RR40, RR807, RAL1015, RAL8017, RAL5005, RAL9003, RAL7004, RAL3020.

However, manufacturers offer a much larger selection of colors and all sorts of shades. Therefore, you can easily choose any color of the material, and do not waste time on painting it after installation.

Note! If it is planned to line the walls with corrugated board, the grades of its coating should also be taken into account. Polyurethane, plastisol, polyester and PVDF are used. Moreover, the material with a polyurethane coating is considered the most hygienic. Because of these qualities, it is most often used for wall decoration in rooms with a high requirement for sanitary and hygienic standards. He is not afraid of ultraviolet, humidity and other influences, and the aesthetic appearance adorns the interior of the room.

Mounting material

Decking of various brands and modifications is not only one of the lightest in terms of weight and transportation, but also very easy to install. .

Although it is called wall, it can be used for finishing balconies, cornices, facades, ceiling cladding, making fences and various ceilings. Repairing dilapidated surfaces with corrugated board cladding will give them strength and durability for many years.

The old wall will not have to be destroyed and rebuilt if it is sheathed with galvanized steel. New walls will last for decades without the need for repair or restoration.

A metal or wooden frame sheathed with profiled sheets will serve as an excellent, strong and aesthetic fence. The possibilities of the material are such that it can be easily fixed in any planes of space.

Horizontally, vertically or at any angle, well-reinforced sheets will last the same long time.

It is worth noting that the lining of the walls with corrugated board is done at the final stage of construction. Work is recommended to be performed in the following sequence:

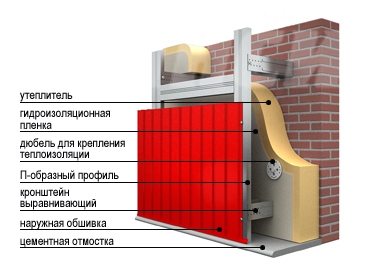

- The wall is being prepared for installation. A special frame is made that performs a load-bearing function.

- The wall is laid out with a layer of insulation of the required thickness and acceptable grade.

- If an insulating layer is expected, it is necessary to use additional corners to level the walls. Corners are also needed for fastening the Z-profile, which serves to create additional space filled with insulation.

- If it is necessary to create space also for ventilation, an additional small Z-profile is mounted, to which the corrugated board will be attached.

- The supporting profile - Z is mounted in steps that take into account the future load created by the material. Too big a step and an unreliable frame can bring safety troubles.

- After installing the frame and laying the insulation, a film is stretched that serves as a wind barrier. It will also protect against unwanted ingress of moisture and, as a result, rotting of the material.

- Sheets of metal are marked out and holes are drilled in the right places with a drill for future fastening to the frame.

- Each profiled sheet is fastened with self-tapping screws screwed into the profile deflection. For each square meter of material, 6-8 screws are required.

- On the side overlaps, the distance between the screws should be about half a meter (if the roof is covered), and about a meter (for wall finishing).

- If the roof is covered, then on the crest or cornice, self-tapping screws are screwed into every second deflection, and in the middle of the sheet, fasteners are made into each crate.

- When building a fence, insulation is not needed. Sheets are attached directly to the frame with a screwdriver and self-tapping screws. It is necessary to ensure that the distance between the screws is the same. The best option for fences and fences can be considered sheets of grade C20 and C21.

- Screws should be selected with the color of the heads corresponding to the color of the material. In this case, they will not spoil the overall appearance of the finish.

As you understand, the installation of profiled steel material is not particularly difficult. Moreover, if the sheets are small in size and thickness, you can easily do without outside help when laying them.

On average, decorating the walls with corrugated board will take you quite a bit of time. Using this material, you will save money on periodic repairs to your walls and roof.

It is worth noting that walls sheathed in this way will last at least twice as long. And if insulation and moisture protection are laid between the skin, you will avoid significant heat losses and the cost of additional heating.

Making a gate, fence or wicket will cost you not only cheaply in cost.

The result will please more than one decade.Many, even the most daring design decisions are realized with the help of this reliable material.

You can choose not only a lot of brands from manufacturers. Options for wave steps, various profile shapes and material thicknesses, sheet sizes, colors - all this is available on the modern market in a large assortment.

You do not even have to spend money and time on painting the finished structure, as the sheets are already covered with layers of protection and paint. Of course, if desired or over time, you can repaint the coating in the color you need.

But the metal profile gives a very large scope for creativity. No wonder we so often see it as a finish on fences and buildings of various designs and purposes.

Did the article help you?