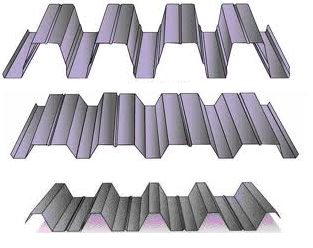

There are quite a few varieties of profiled material, each of which is designed for specific purposes. An original and truly revolutionary idea for modern construction has become a load-bearing corrugated board, which is used almost everywhere. Overlappings that carry a sufficiently large load, roofs are most often mounted using this material.

There are quite a few varieties of profiled material, each of which is designed for specific purposes. An original and truly revolutionary idea for modern construction has become a load-bearing corrugated board, which is used almost everywhere. Overlappings that carry a sufficiently large load, roofs are most often mounted using this material.

Workshops, industrial enterprises, shopping centers, large warehouses and much more are decorated in various places with powerful sheets with a wavy surface.

It is where a large load on the building structure is expected that it is best to use wall decking, intended for carrier functions.

What is the difference between the supporting metal profile and the rest

Note! All types of profiled materials have a corrugated surface. This is done for increased rigidity of the material, because rather thin sheets are used for its production. And it is specially made longitudinal waves that give it the required strength and resistance to stress.

Roof decking has an average weight of up to 8 kg per square meter.

Compare this weight with the heaviness and bulkiness of reinforced concrete slabs, and it will become clear that using corrugated board is much more profitable.

What is the difference between the profiled material made of galvanized steel and the long-familiar concrete structures?

- Light weight with amazing strength.

- Inexpensive cost compared to other materials.

- Ease of transportation, as well as quick and easy installation.

- There is practically no pressure on the walls and foundations of buildings, unlike heavy concrete floors.

- Galvanized and coated with a polymer creates a reliable protection and durability of the sheets.

- High coefficient of resistance to various kinds of influences. It is not afraid of moisture, does not collapse under the influence of high and low temperatures. Resistant to mechanical stress, fire, ultraviolet.

- Hygienic, does not pollute the environment.

- Thanks to additional grooves, it acquires increased rigidity, durability and reliability.

- Perfect for mounting not only ceilings, but also as a roofing. In this case, it lasts even longer than conventional profile sheets.

- The service life not only meets the standards, but also exceeds all other materials.

Of all the varieties of corrugated galvanized steel, the load-bearing version is also distinguished by the fact that it has the greatest thickness of the sheets. If for ordinary corrugated board a thickness of 0.5 mm is considered to be average, then for this type of building material it is the minimum.

This is not surprising, because the bearing capacity of corrugated board has a very high coefficient. And additional longitudinal recesses increase the rigidity several times. The height of the corrugations also differs from the standards, and averages from 44 mm to 115 mm.

It is generally accepted that this type of material may be used not only for roof installation, but also overlaps. This is so, the floors are extremely durable and reliable.

However, from the bearing variety, excellent roof coverings, powerful fences and gates, and heavy containers are obtained. You can build a private garage, and a huge hangar - these buildings will serve for a very long time, without rusting and without requiring repair.

Quite a lot of brands of sheets of this particular category are produced. Each of them has its own characteristics and features, which we will now discuss in a little more detail.

Material characteristics

It is known that each type of corrugated board is marked with a marking indicating its main purpose.

The material we are talking about now is denoted in the nomenclature by the letter “H”, which means “carrying”. But there is also the brand "NS" - bearing-wall. The latter differs only in the height of the corrugation - it is less than that of the carrier, and is 35-44 mm. .

Accordingly, it is not intended to carry too much load, and is used more for cladding walls and roofs than for mounting powerful ceilings.However, non-industrial buildings of medium size (sheds, garages, gates and fences, etc.) can be built from it without fear for the safety of the structure.

Grade "H" has a corrugation height of 60-114 mm and is used for mounting the strongest and most reliable metal structures.

This corrugated board - its bearing capacity is considered the highest, is ideal for the manufacture of ceilings, formwork of a fixed type, roofing of industrial buildings, interfloor partitions, and much more.

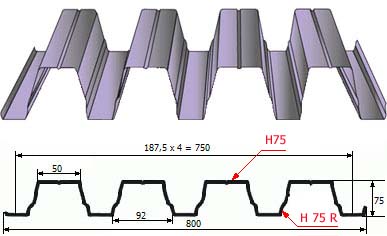

Next to the letter marking the purpose of the material, manufacturers put a number. It means the height of the corrugations of the sheets. Here are the technical characteristics of some types of corrugated board:

- H 60 845. GOST 24045-94, profile 60 mm high, sheet thickness 0.5 - 1.0 mm, overall sheet width - 902 mm, sheet useful width - 845 mm, polymer or galvanized coating, bearing capacity - medium;

- H 75. GOST 24045-94, profile 75 mm high, sheet thickness 0.5 - 1.0 mm, overall sheet width - 800 mm, useful sheet width - 750 mm, galvanized coating, bearing capacity - high;

- H 114-600. GOST 24045-94, profile 114 mm high, sheet thickness 0.7 - 1.2 mm, overall sheet width - 646 mm, useful sheet width - 600 mm, polymer or galvanized coating, bearing capacity - the highest.

- H 114-750. GOST 24045-94, profile 114 mm high, sheet thickness 0.5 - 1.0 mm, overall sheet width - 800 mm, useful sheet width - 750 mm, polymer or galvanized coating, bearing capacity - the highest with increased sheet width.

- H 57.GOST 24045-94, profile 57 mm high, sheet thickness 0.4 - 1.0 mm, overall sheet width - 750 mm, useful sheet width - 700 mm, polymer or galvanized coating, bearing capacity - high.

Note! In most cases, before the construction of a particular structure, it is required to calculate the future load factor and calculate the bearing capacity of the material. Calculations are made based on data on the maximum loads on a certain brand of profiled sheet. It is worth noting that the data attached to each brand indicate the average possible load. The ultimate load is directly proportional to changes in the design. The calculation is made from the value of kg / m, that is, the load at a step of 3.5 m is adjusted by a factor of 0.735.

Bearing capacity and application

As we understood, the bearing capacity of the material depends on the thickness of the steel and the height of the corrugations. Increased strength of the material is given by additional grooves made in addition to the main waves on the profile.

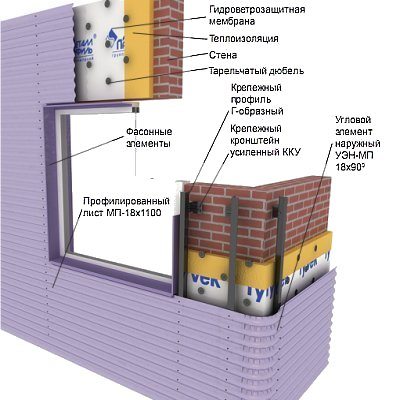

If the material has an average bearing capacity, corrugated board can be used in the same way as ordinary profiled sheets. That is - for roofing, building garages, utility rooms, fences, or for wall cladding.

An additionally laid insulating layer will create, together with galvanized steel material, an ideally strong and durable protection. For example, a roof or walls finished with sheets with an average corrugation height will last 50 years or more without changing their qualities.

There is no need to paint the surface, as the sheets are already covered with a layer of zinc, a protective polymer and paint.The color scheme is very diverse, so there will be no problems in choosing.

Advice! It is desirable to use corrugated board with a high bearing capacity coefficient for roofs with a slight slope (less than 7 °). Note - the thicker the sheet, the more snow it will withstand in winter. For roofs of large buildings, where snow cover will accumulate in very large quantities, load-bearing material grades are simply irreplaceable.

The material is in great demand where it is necessary to perform fixed formwork. Sheets in this case serve as the basis for interfloor ceilings.

The reinforcement laid on them and pouring with a mixture of concrete makes the ceiling ideally strong and durable. The advantages are obvious - the cheapness and speed of the method, ease of transportation and no need for additional building materials.

Therefore, the bearing type of profiled sheets is used almost everywhere where buildings, enterprises, factories, shopping centers and much more are being built.

Did the article help you?