In the article I will tell you how to properly cover the roof with corrugated board, starting from the selection of material and ending with the technology for attaching it to the crate. The information provided will help you plan the work correctly to achieve the desired result with minimal time, effort and money.

Advantages and disadvantages

The use of a profiled metal sheet as a roofing material has a number of advantages:

- Strength and durability. Subject to proper selection and installation in compliance with all requirements, a corrugated roof can last 30 years or more without requiring repairs.

- Resistance to external influences. In the production of high-quality corrugated board, the steel base of each sheet is covered with several layers of anti-corrosion coatings. Due to this, the metal does not rust and retains its strength.

- Light weight. The mass of corrugated board is about 6 - 8 kg / m2, which allows you to lift it to the roof without the use of special equipment. The second plus is low load on carriers designs (rafters, lathing), which allows you to save money by using thinner beams and boards.

- Fire safety. The profiled sheet not only does not burn itself, but also prevents the spread of fire.

- Price. If we exclude the cheapest slate, then covering the roof with corrugated board can be safely called the most affordable technique. If you want to save money - choose corrugated board.

Now - about the cons:

- Cut corrosion. As I noted above, cut edges and places where we screw in screws are potential sources of corrosion. The condition of the metal base in these areas must be monitored, and measures should be taken at the first sign of rust.

- Heating in the sun.In the summer, the roof of the profiled sheet heats up very much, so that both in the under-roof space and in the room itself, the temperature also increases. This problem is partially solved by the installation of thermal insulation on the inside of the roof slopes, but only partially.

- Terrible soundproofing. For me, this is the most serious drawback, which significantly limits the use of corrugated board as a roofing material for residential buildings. You can hear everything - rain, hail, wind, birds, even cats! Again, a layer of thermal insulation using porous materials partially absorbs sound, but does not completely remove it.

The issue is the appearance. On the one hand, the corrugated roof looks neat, and in some ways even ascetic. On the other hand, you can’t confuse corrugated board with other roofing material, because the roof will still look “cheap” to some extent. That is, there is not much difference for a garage or a barn, but the design of a residential building may suffer.

What do you need to work?

materials

Be that as it may, but very often the positive properties of the profiled sheet outweigh, and it is chosen as the main roofing material.

To install a corrugated roof with your own hands, you will need:

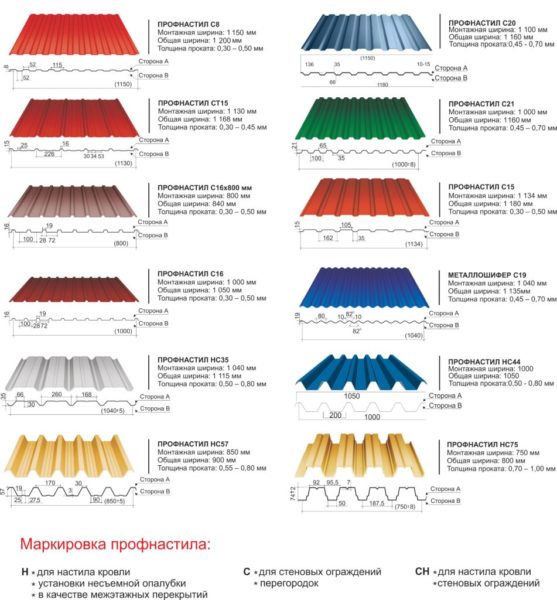

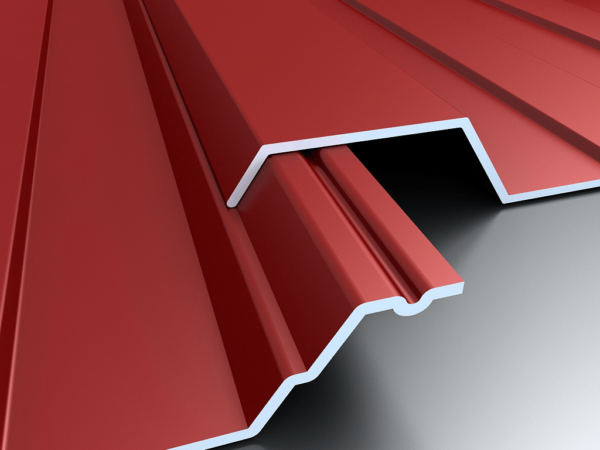

- The corrugated board itself with a base thickness of 0.5 to 0.7 mm. For roofing work, grades from C8 - C21 to C44 - H60 are suitable. The lower the planned load on the roof, the smaller the profile size you can choose.

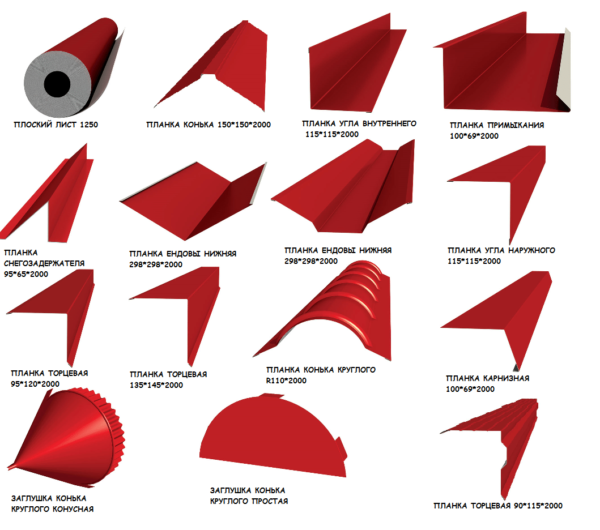

- Additional elements from the pro-thinned-out metal. This should include internal and external valleys, end strips, drips, overlays to mask the junction with walls, etc.

- Lumber for creating a crate - bars 40x40 or boards 100x30 mm.

- Plate materials (plywood, OSB-plate) 15 mm thick to create a continuous crate.

- Roof waterproofing membranes.

- Thermal insulation materials (most often plates based on mineral fiber).

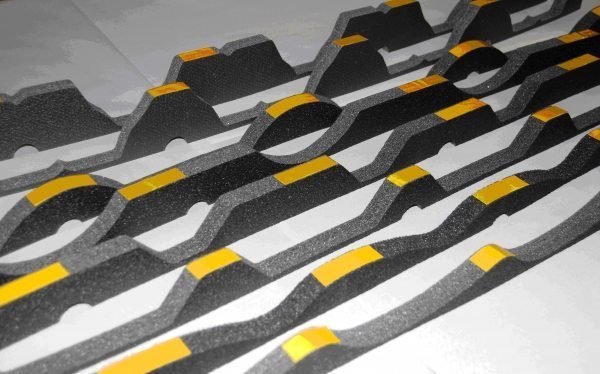

- Sealing tapes for filling cavities along the perimeter of the roof. It is best to purchase a tape made of porous material, the profile of which matches the profile of the roofing sheet.

- Fasteners - nails and self-tapping screws for mounting the crate, self-tapping screws for corrugated board.

For additional materials, I would include a vapor barrier membrane designed for installation on the inside of an insulated ramp. It is also worth purchasing an antiseptic impregnation for wood, which we will process and rafters, and details of the crate.

Tools

To properly cover the roof with corrugated board with our own hands, we need the following tools:

- Wood saw for cutting beams, boards and plywood for sheathing.

- Manual or electric metal shears for cutting corrugated board.

In no case should you cut the profiled sheet with a grinder. When in contact with a grinding or cutting disc, the metal heats up, which leads to the destruction of the anti-corrosion coating. As a result, the roof will rust very intensively at the cut line.

- Screwdriver for fast tightening of self-tapping screws.

- Construction stapler.

- Knife for cutting waterproofing membranes.

- Knife or saw for insulation.

- Measuring tools - plumb, level, tape measure.

To increase productivity and ensure safety, it is important to properly organize work at height. You need to move along the slopes of the roof only with insurance securely fixed in the area of \u200b\u200bthe ridge. It is desirable to carry tools in a special belt with pockets.

Another tip is to fence off the area adjacent to the roofing site. So you reduce the risk of injury to others, because both tools and roofing parts tend to fall at the most inopportune moment.

Preparation

Calculation

In order to properly cover the roof, it is necessary to perform at least an approximate calculation of the bearing capacity of the crate. If you make it too rare, then the corrugated board will “play” under its own weight, which will eventually lead to weakening of the fasteners and the appearance of leaks.

On the other hand, too dense crate requires the use of a large amount of material. Hence the increase in weight load, and the rise in the cost of the structure as a whole.

To choose the optimal crate step, you can use the table:

| Type of corrugated board | Roof slope, degrees | Lathing pitch, mm |

| C- 8 | from 15 | solid |

| C - 10 | from 15 | 300 |

| less than 15 | solid | |

| C - 20 | from 15 | 500 |

| less than 15 | solid | |

| C - 21 and over | from 15 | 650 |

| less than 15 | 300 |

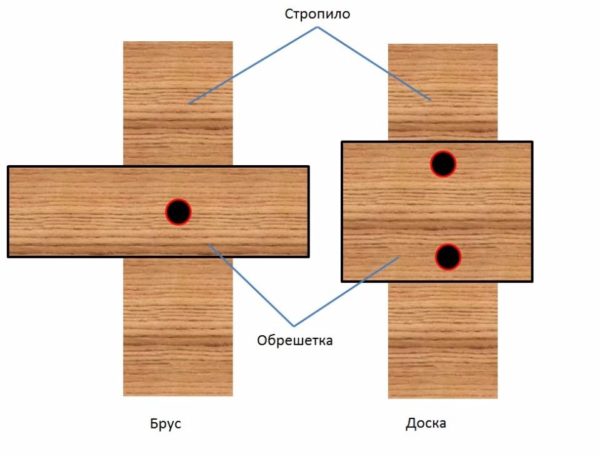

The calculation is given for a sparse crate, for which boards 100 x 30 mm or bars with a section of 40 x 40 or 50 x 50 mm are used.

When installing a continuous crate, plywood with a thickness of 15 mm or more is used.Oriented strand board (OSB) of similar thickness and load-bearing capacity may be used.

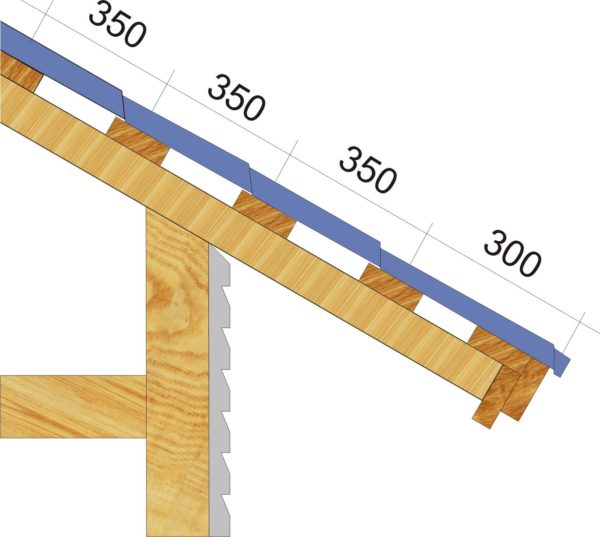

When calculating the volume of purchases of materials for mounting the battens, it must be borne in mind that not only the width and length of the roof slope are taken into account. It is also necessary to take into account the roof extension (horizontal protrusion beyond the pediment) and overhang (lateral protrusion beyond the Mauerlat front). In these areas, a crate is also made under the roof, so the purchase of material must be carried out taking into account the dimensions.

Thermal and waterproofing

Before covering the roof with a profiled sheet, we need to compensate for its shortcomings - weak heat and sound insulation performance. In addition, additional waterproofing should be provided: no matter how well we install the profiled sheet, there will still be leaks.

Work on the formation of the "roofing pie" is carried out according to the following scheme:

- Between the rafters we lay plates of heat-insulating material - mineral wool with a thickness of 75 to 150 mm. From the inside, we block the insulation with a vapor barrier membrane and fix it with a counter-lattice - transverse bars or plywood sheathing.

- From the outside, we install a vapor-permeable waterproofing membrane. The vapor permeability of the material is very important, since it maintains the natural ventilation of the roof and prevents condensate from accumulating in the thermal insulation layer.

- When installing waterproofing, we roll out the membrane rolls horizontally, descending from the ridge to the cornices. We fix the material on each rafter with several galvanized brackets.

- An important parameter is the size of the material overlap: the smaller the slope, the wider the double layer should be at the junction of the rolls. The optimal overlap for slopes with a slope of 30 degrees or more is 150 mm, for slopes with a slope of 12 - 15 to 25 -28 degrees - at least 200 - 250 mm.

- To minimize the risk of water leakage, you can use double-sided adhesive tape (almost every waterproofing manufacturer has it in its product line). We glue all the joints with tape, securely fixing them and protecting them from displacement.

crate

To cover the roof in accordance with all the rules, we need to mount a reliable crate.

To do this, focusing on the above calculation, is easy:

- For the crate, we take boards and bars with suitable sizes. The optimal wood species are pine, larch spruce. The maximum allowable humidity is 18%, if more, then it is advisable to dry the wood in the shade, avoiding cracking.

- Before buying, we check the parts for knots, rot and wormholes. The appearance of wood is not so important, but strength comes first. So if there are defects, it is better to refuse the purchase.

- It is also worth checking the geometry of the beam / board. We don’t need a perfectly smooth surface, so you shouldn’t buy expensive jointed materials. Curvature is another matter: the smoother the parts are, the better the frame will turn out, and the less effort we will spend on its installation.

- Even if outwardly the tree looks perfect, we treat it with antiseptics. It is advisable to take an indelible composition with a high content of active ingredients. The disadvantage of such products is the staining of wood, but in our case this disadvantage does not play a role.

An additional advantage in processing can be a decrease in the combustibility of wood. such an effect is ensured, for example, by the use of the composition "Senezh OgneBio Prof" or similar solutions.

Now - the installation of the supporting structure itself:

- First, we fill thicker boards on the ends of the rafters - the so-called cornice supports. Under the cornice support, you can lay a thin metal corner - a dropper. It is inserted under the waterproofing material and ensures effective hardening of condensate from the wall surface.

- We lay the elements of the crate perpendicular to the rafters. For fixing, we use either nails or phosphated wood screws.

- We fasten the beam on the rafter at one point, the board - at least two. By fixing the board from above and below, we prevent its deformation: if you install a nail in the middle or only on one side, then a sufficiently wide element can “wave”.

- During installation, we control the geometry of the crate. The permissible deviation is about 2 mm per 1 m. It is convenient to use two levels for control: long - 2 m, and short - 50-60 cm.

- When installing the crate on a wide roof, it becomes necessary to join the beams. According to the rules, docking is carried out only on the rafters: the parts are cut, each edge is fastened with separate fasteners, after which a connecting bracket is hammered into both boards.

- Finally, on the bottom of the slopes, you can install fasteners for gutters. We fix these parts either to the eaves board or to the end beam, which is stuffed onto the rafters themselves.

So, the future roof is insulated, the waterproofing is laid and the supporting structures are mounted. Now it remains for us to actually cover the roof, fixing sheets of corrugated board and additional elements on it.

Roofing

Profiled sheet installation

Fixing the roofing material on the crate with our own hands, we begin with the installation of additional elements located under the corrugated board. As a rule, these are lower valleys, which must be fixed at the junction of planes to protect against leakage, and cornice strips.

When this operation is completed, you can proceed to sheathing the main surface of the slopes.

The instruction assumes work in the following sequence:

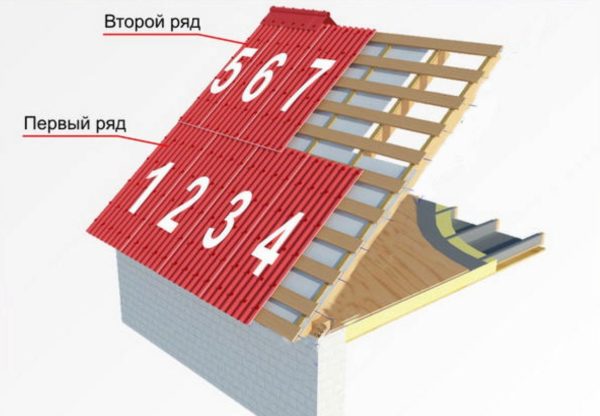

- The starting point is the lower left corner of the ramp. If you start here, then you can most effectively overlap the sheets with the overlap of the capillary grooves.

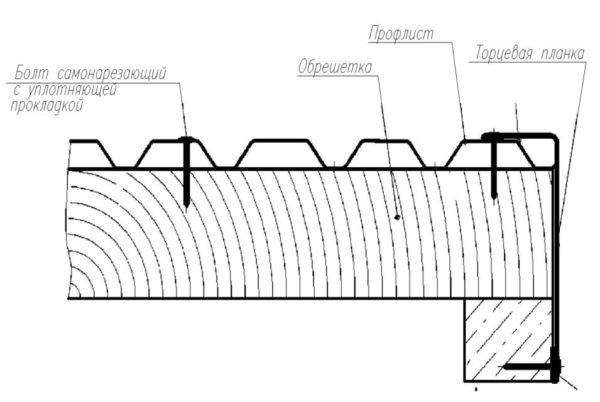

- To begin with, we lay several sheets, align them with the gable extension and the cornice overhang, and fix each with one self-tapping screw. We mount a sealing tape along the end of the corrugated board, covering the gap between the crate and the corrugated parts of the material.

- When laying, the extreme left wave of the sheet is superimposed on the extreme right wave of the already laid one. This overlap is essential as it ensures no leakage.

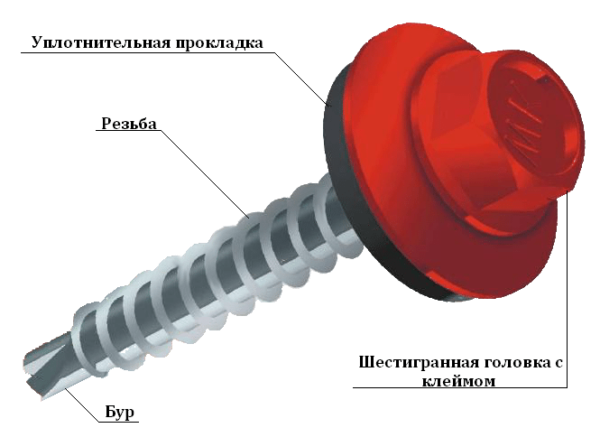

- After a few parts have been laid (I usually mount three sheets in the first row from the bottom, and two in the second), we begin the final alignment with fixation. For fastening, we use self-tapping screws with a hex head and a sealing washer.

- Fastening is carried out in the lower part of each even wave of the corrugated sheet. After that, we make from 4 to 10-12 attachment points per square meter of material, distributing self-tapping screws in a checkerboard pattern.

- Separately, we fix the joints of the sheets with self-tapping screws. You can simply pull the corrugated board with ordinary fasteners, but I prefer to screw long self-tapping screws into the overlap. They reach the crate and give the structure additional rigidity.

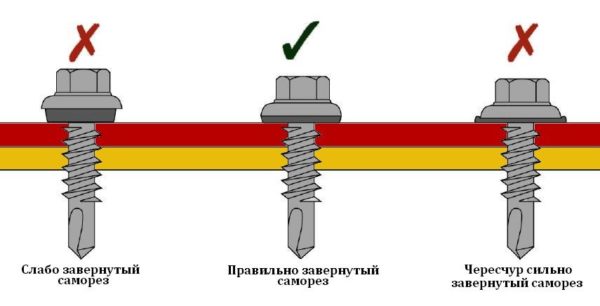

- When we independently cover the roof with corrugated board, it is extremely important to control the tightening forces of the fasteners. The neoprene pad should be pressed against the metal, but not crushed or warped. With proper compression, the material self-vulcanizes, and the fastener is almost sealed.

- When working with thin (0.5 -0.6 mm) corrugated board, it is also important to avoid deflection at the fastening point. The consequences of excessive tightening will be the formation of dents, in which water will linger when draining, and sooner or later will seep inside.

- Another trick is pre-drilling. If a profiled sheet with a thickness of 0.6 - 0.7 mm is used for the roof, then holes should be drilled at the fastening points, the diameter of which will be approximately 0.1 - 0.2 mm larger than the diameter of the working part of the self-tapping screw.So we will facilitate installation and, in addition, ensure the mobility of the roof during temperature deformations.

- We cut the extreme top and side sheets in length / width and fix them on the crate with additional fasteners.

The installation method described in the section is used when roofing the roof with a fixed-width piece corrugated board. At the same time, now it is possible to order material, the width of which will be equal to the width of the roof itself - in this case, you do not have to spend time joining individual sheets.

Installing additional parts

Mounting a profiled sheet on slopes is the most time-consuming, but not the most painstaking part of the work.

After completing this stage, we need to install additional items:

- At the junction of the rafters on the ridge beam, we install the board on the edge and fix it with metal corners. We lay a ridge profile on top of the board, which we fasten with self-tapping screws.

We glue a porous sealant tape under the side rails of the ridge profile, which will ensure the tightness of this assembly.

- We mount end strips along the gables. The vertical part of the plank is attached to the end board of the crate, the horizontal part covers the extreme wave of the corrugated board and is fixed on it. Under the end plate, you can also lay a sealing tape.

- Where the planes of the slopes meet, we put the upper valleys.

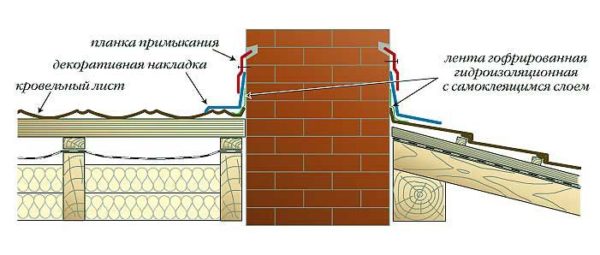

- We cover the joints of the profiled sheet with chimneys, a vertical wall and other surfaces with corner parts - an abutment bar.

- Under the bar, we must lay the sealing material, and fasten the part itself with elongated self-tapping screws that reach the crate or rafters. The point of contact between the plank and the wall can be additionally sealed with a liquid compound or butyl tape.

Conclusion

A roof made of corrugated board, built according to this scheme, will provide effective protection of the house from moisture for many years. To understand the technology in more detail, you should study the video in this article. In addition, questions regarding complex stages of work can be asked in the comments.

Did the article help you?