The article is devoted to the reliability and durability of the roof, which directly depend on the method of fixing the roofing material. Mounting the profiled sheet on the roof has its own characteristics, which must be studied before starting work. I will talk about the technical nuances so that you can independently fix the material and not worry about the final result.

Process Features

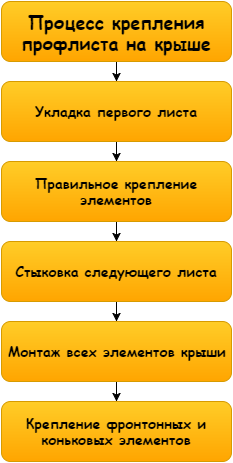

We will analyze the process in great detail and break it down into the following steps:

- The choice of fasteners depending on the configuration of the roof;

- Fastening elements.

Stage 1 - the choice of profiled sheet and fasteners

The type of fastener directly depends on the choice of a profiled sheet, so first of all decide on this aspect:

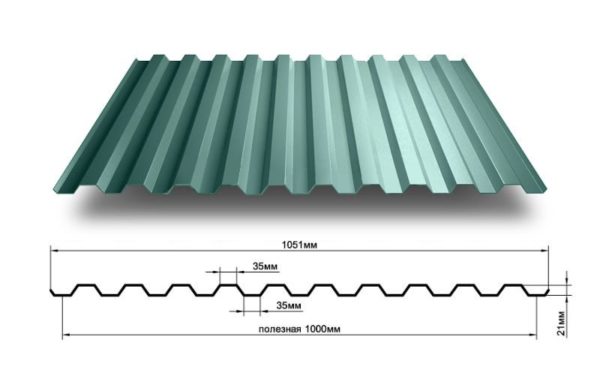

- The simplest option is marked "C", this is a wall version with a wave height of 8 to 44 mm. It is distinguished by a low price, but it is not very suitable for roofing. I advise using such products for sheds and small buildings;

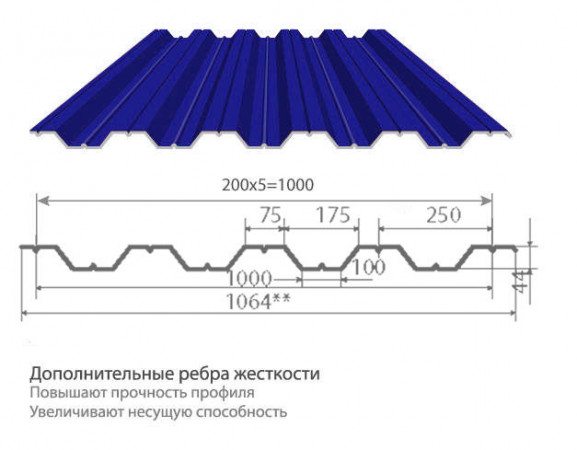

- The NS brand is suitable for both walls and roofing systems. The height of their corrugations is usually from 35 to 44 mm, but if the options are lower and the wave is lower. This is the so-called "golden mean", which I recommend to use on houses and other buildings;

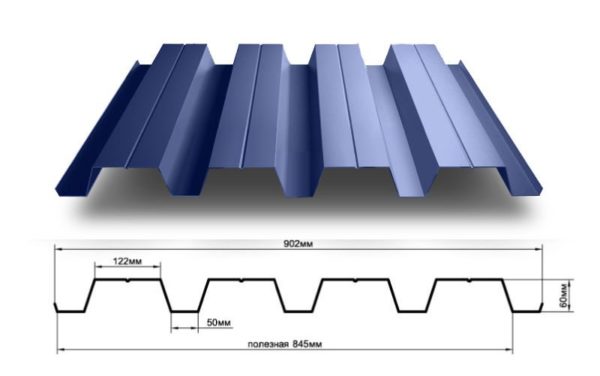

- The most durable option is marked "H" and has a wave from 57 to 114 mm. Such sheets are always made with stiffeners, but due to the high profile they are most suitable for industrial buildings.

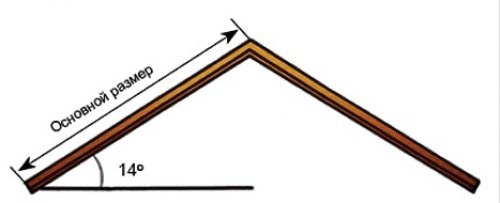

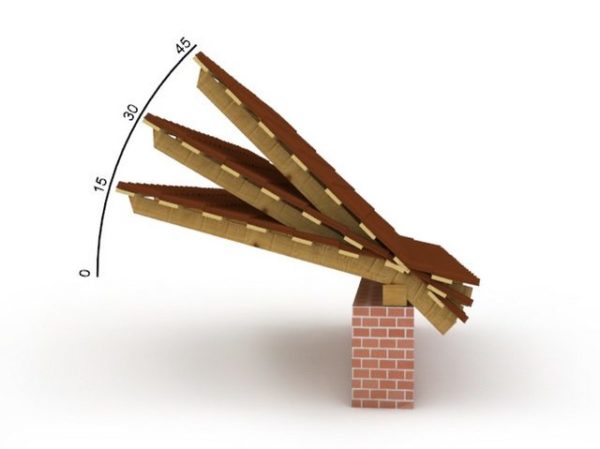

It is necessary to take into account the slope of your roof, the size of the overlaps at the joints depends on this.

Three main options:

- If the angle of inclination is less than 14 degrees, then the overlap at the joints must be at least 200 mm. Plus, it is recommended to additionally protect the joints with sealant;

- For a ramp slope of 15 to 30 degrees, an overlap of 15-20 cm is required without additional sealing of the joints;

- If the angle is more than 30 degrees, then the overlap can be 10-15 cm.

Another factor influencing the choice of fasteners is the design of the crate.

And there are two options here:

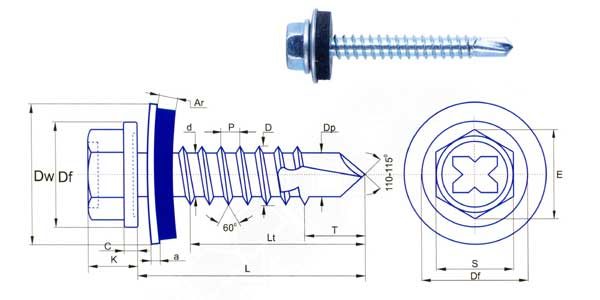

- Fastening to metal purlins is carried out using special self-tapping screws for metal with a large drill tip. Their length must be at least 25 mm for the main attachment and 70 mm for the gable and ridge elements. Fasteners must be the same color as the main coating, everything is easy here, because the material is RAL marked;

- The profiled sheet is fastened to the wooden crate using self-tapping screws with a smaller drill. Typically, fasteners with a length of 29 or 35 mm are used to fasten the main elements, and a 70 mm option is used for skates and slats.

Stage 2 - fastening process

If everything you need is at hand, then you can get to work.

Let's figure out how to fix the profiled sheet on the roof:

You need to work with a good screwdriver, for which you can purchase an M8 magnetic nozzle. With its help, it will be very convenient to carry out the fastening.

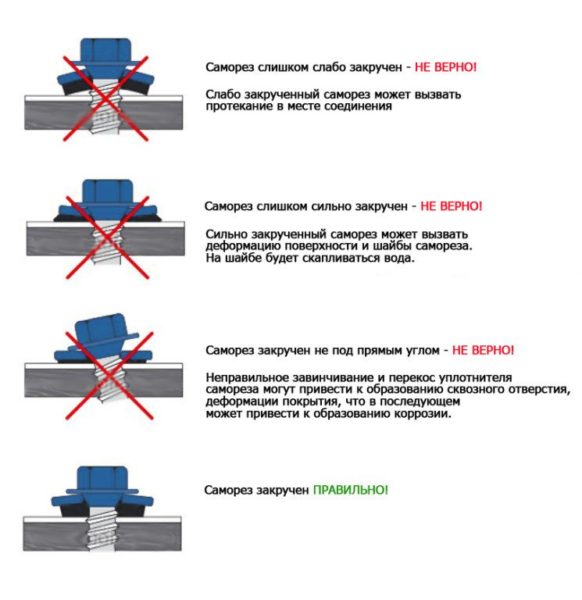

- It is important to place the first sheet correctly. Firstly, you need to set it according to the level, and secondly, set the overhang, it should be no more than 10-15 cm. You also need to figure out how to properly place the screw, the diagram below shows the correct and incorrect mounting methods, it is very important to immediately understand this aspect;

- It is important to understand that the profiled sheet is always attached to the bottom of the wave. You don't need to twist over the top of the waves as you can warp the material if you don't control the twisting force.. In the process of carrying out the work, it is important to monitor the correct position of the screwdriver, it must be perpendicular so that distortions do not occur;

As for the consumption of fasteners, it usually takes 6-8 pieces per square meter. Fastening is usually done through a wave. The vertical distance between fasteners depends on the pitch of the crate and is 40-50 cm.

- Remember that corrugated roofing with a slight slope is fastened using sealant at the joints. From the edge of the sheet in the upper part, you can retreat 3-4 centimeters. If the elements are also joined along, then the overlap should be at least 100 mm, and preferably 150-200 mm;

- Work continues until the entire surface is covered. If your roof profile is broken, that is, the angle of inclination changes, then you need to pay attention to the connection of the sheets. The upper element must be bent so that it goes 30-40 cm beyond the bend, and the next sheet is already under it. This is the only way to ensure reliable docking;

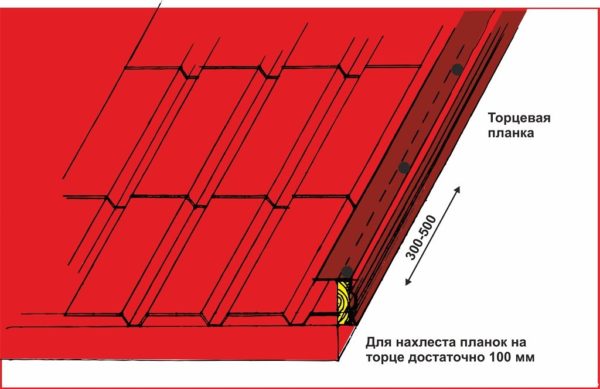

- After the profiled sheet is fixed, you can proceed with the installation of the end strips. They must extend to the surface by at least 100 mm. Fastening is carried out in increments of 30-50 cm, the length of the self-tapping screw must be such that it enters the frame by at least 30 mm. I usually use the 70mm option just to be sure;

- Lastly, the skate is attached. I advise using this technology: a special vapor barrier tape is glued along the edges along the element location line, which will close the joint, but will not interfere with normal air exchange. Roofing screws are screwed along the edge in increments of about 20 cm.

You need to fasten the corrugated board to the roof from metal trusses in exactly the same way, the only difference is that the screws should come out of the metal from the back by 7-8 mm. This ensures reliable fastening of the material to the surface.

Conclusion

From the article, you learned about the best option for fastening a profiled sheet using roofing screws. This review will give you the opportunity to do the job right and get the perfect result. The video in this article will help you understand the topic even better, and if something is not clear to you, then write your questions in the comments below.

Did the article help you?