The material from which the roofing of a residential building or industrial facility will consist depends on your wishes and financial capabilities, as well as on the type of roof. Its durability on the roof will depend on the quality of installation, the standards for which are given in the SNIP for corrugated roofing. From this article, you can find out the main points of the roof with corrugated board, the basis for the implementation of which are general regulatory requirements.

The material from which the roofing of a residential building or industrial facility will consist depends on your wishes and financial capabilities, as well as on the type of roof. Its durability on the roof will depend on the quality of installation, the standards for which are given in the SNIP for corrugated roofing. From this article, you can find out the main points of the roof with corrugated board, the basis for the implementation of which are general regulatory requirements.

Material characteristic

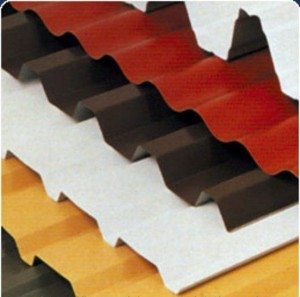

As you guessed, we are talking about corrugated roofing.Therefore, we will pay a little attention to the characteristics of this building material. Decking is obtained from galvanized sheet by cold rolling.

A profile in the form of a wave or a trapezoid is covered on both sides with an anti-corrosion, resistant coating, which differs in application technology and color.

Decking has several categories of destination:

- roofing material;

- wall elements;

- bearing structures.

Each category differs in the height of the corrugation (stiffening rib), the thickness of the metal, and the designation.

Profiled sheeting with the designation C is used as a wall material, H - roofing, HC - it is possible to use both in wall and roofing designs. In addition, profiled sheets can be produced with different metal thicknesses, but the same height. The length of the profile can be from 0.5 to 12 m.

Attention. For roofing, in most cases, a material is used whose profile height is higher than 35 mm. And on roofs with a short slope length, a profile with a wave height of 21 mm and the designation H, HC is used.

Use of roofing material

The use of profiled sheets with a corrugation height of 44 cm for roof installation is due to - roofs from SNIP corrugated board, the provisions of which provide for the use of steel profiles with aluminum or zinc coating, which has an additional polymer-based coating, as roofing.

The polymer coating acts as a protective and decorative layer.

The basis for corrugated board can serve as:

- metal runs;

- wooden bars.

According to building regulations, their bearing capacity is determined based on the load on the roof of the base material and the wind force of a particular climatic zone.

Aprons are provided, made of galvanized metal sheets with a polymer coating for adjoining the profiled sheet of the roof to the wall.

Shaped roofing elements for finishing corrugated roof gaps have a comb similar to the profile cross-sectional view.

In addition to shaped elements (ridge, cornice, gutter), roofing accessories are used in the arrangement of the roof:

- snow barriers;

- plugs;

- ridge seals and more.

A solid base is mounted at the guttering point. Its thickness is similar to the thickness of the crate.

Profiled sheets can be used as:

- piece roofing sheet for cold (not insulated) roofing;

- a sheet as part of an insulated coating made by assembling several layers.

Constructive decisions

According to building codes, the expedient use of profiled sheets is indicated on buildings whose slope length does not exceed 12 m. With an increase in the length of the slope, the roofing profiled material is mounted along the slope with an overlap of 200 mm, in the transverse direction from the slope - an overlap in one wave.

Between themselves, the corrugated board is fastened with self-tapping screws having a sealing washer 1 mm thick.

On roofs with a small slope, the transverse and longitudinal joints of profiled sheets are sealed with silicone or thiokol sealants. Fastening of additional elements of the roof to the corrugated board is carried out with rivets.

The presence of one or two ventilation ducts on the roof of a metal profile depends on the constructive solution. Ventilation is carried out through a pipe or ridge.

roof slope

Profiled sheets are preferably used on the roofs of buildings with an inclination angle of 20 degrees. It is allowed for industrial facilities with a self-supporting profile, the minimum slope of the roof from corrugated board is at least 8 degrees, and for residential buildings - from 10 degrees.

The joint of the corrugated board along the length is overlapped depending on the slope:

- at an angle of 15-30 degrees - an overlap of 200 mm;

- 30 degrees or more -150 mm;

- less than 15 degrees - overlap on two waves with sealing of joints.

As we have already indicated, the corrugated board is laid on a wooden base. Depending on the slope of the roof, the pitch of the base lathing changes.

It can be from 300 to 4000 mm. As the angle of inclination increases, the pitch increases. Building codes stipulate that the deviation of the slope from the specified level should not exceed 5%.

Advice. On roofs with a small slope, it is more expedient to use a continuous crate.

Lathing device

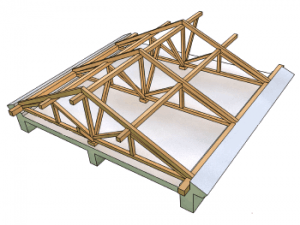

For profiled sheets, the lathing device is performed as follows:

- The frame of the crate is attached to the truss system;

- For manufacturing, bars of 50x50 mm are taken;

- The step of the crate can be continuous or have a certain category.

According to SNIP, for a roof with a slope of 20 degrees, the step is 20-40 cm, and the minimum thickness of the planks is 30 mm. The laths of the crate, which are placed along the eaves, should be thicker than the main ones.

Attention. On roofs, at the points of exit of chimneys or ventilated pipes, additional lathing is required.

Mounting materials

Materials, mounted in strict sequence and correctly, form a roofing pie for corrugated board. According to the building rules, the design of the roofing pie includes:

- main cover;

- insulation;

- insulating membranes.

Each layer in this design is inextricably linked and has a specific meaning. An error in the construction of one leads to a decrease in the main characteristics of the roof and its service life.

Structurally well-assembled "pie" excludes the following phenomena:

- heat loss;

- soak;

- formation of condensate;

- ice formation.

The main building rules for roofing include its effective thermal insulation, which:

- minimizes heat loss through the roof;

- prevents surface condensation.

Installation of insulation is carried out between the rafters. According to SNIP, a wind barrier must be installed on the insulation to prevent blowing through the coating. In its capacity are rolled material vapor-permeable material.

The seal performs the following functions:

- stops the heating of the roof space;

- soundproof the room.

According to the norms of SNIP, the thickness of the insulation for our area is 250 mm.

The vapor barrier layer in the roofing cake prevents moisture from entering the insulation from the room.

Vapor barrier films are attached to the inside of the heat-insulating layer in a vertical or horizontal direction in relation to the supporting wooden structure. The size of the overlap when laying is 10 cm.

The waterproofing layer protects the insulation from the penetration of condensate, which forms from the bottom of the profiled sheets.Waterproofing membranes or films are attached to the rafters in a horizontal direction.

When laying, the following requirements are met:

- they are laid on rafters, the distance between which is not more than 1.2 m;

- sagging of the film in height should not exceed 2 cm.

Attention. When installing waterproofing, the protective layer should not touch the surface of the insulation.

Coating insulation

When installing insulated coatings to reduce the effect of heat and cold, thermal profiles are used as a purlin, and between the corrugated board and the purlin, a 10 mm thick gasket made of baked plywood painted with vinyl chloride enamel is provided.

For do-it-yourself corrugated roofs with heat-insulating material belonging to 1-4 flammability groups, it is planned to fill the corrugations of the flooring with materials of non-combustible groups to a length of 25 cm at the junction of the coating and walls, as well as on the sides of the ridge.

Installation of profiled sheet on the roof compliance with the construction requirements and rules described in the article is provided. Only accurate execution will ensure that the roof structure is reliable and brings comfort to all people living in the house. So, let's hope that you now know for sure how to cover the roof with corrugated board

Did the article help you?