The structure of the roof covered with corrugated board, along with durability, looks beautiful, as this material has a wide color palette. In this regard, the demand for this roofing is growing. Accordingly, many are also interested in technology, that is, how to make a roof from corrugated board with their own hands. These points are the focus of this article. It will come in handy even if you do not carry out roofing work yourself. Knowing the technological moments, you will be able to control the work of the roofer for quality performance.

The structure of the roof covered with corrugated board, along with durability, looks beautiful, as this material has a wide color palette. In this regard, the demand for this roofing is growing. Accordingly, many are also interested in technology, that is, how to make a roof from corrugated board with their own hands. These points are the focus of this article. It will come in handy even if you do not carry out roofing work yourself. Knowing the technological moments, you will be able to control the work of the roofer for quality performance.

Preparation for roofing work

Covering the roof with corrugated board provides for the preparatory stage of work. To get started, you have to:

- draw up an estimate for roofing work;

- purchase materials for the base and roof covering;

- transport them to the site.

The estimate for the roof of corrugated board varies depending on the following factors:

- conditions for performing work (on their own or with the help of roofers);

- size and design of the roof;

- applied materials.

A variety of assortment of corrugated board in the construction market allows you to choose a material that differs not only in color, but also in the brand, on which the thickness and height of the profile sheets depend. A wooden truss system is used as a base for profile sheets.

The main feature of the preparatory stage is transportation. It depends on its quality whether the corrugated board will perform its functions at the maximum level or will give you disappointment and a lot of trouble.

Advice. Profile sheets marked C can be used as roofing. But experts recommend using material marked HC, especially if a flat corrugated roof is to be installed.

Material use

The frequent use of this material is due to its relative price and reliability. Profiled sheets are used if the length of the roof slope does not exceed 12 meters. The slope of the corrugated roof must be at least 8 degrees.

The widespread use of this roofing materialhaving two slopes and a slope of more than 15 degrees.

The slope angle determines the features of the installation of the roof - an overlap in one or two corrugations, and the type of lathing device:

- with a minimum slope (flat roofs) - the pitch of the crate is 3000-4000 mm;

- values with mean roof pitch angle - 500-1000 mm;

- roofs with a large slope - 300-650 mm.

Laying waterproofing

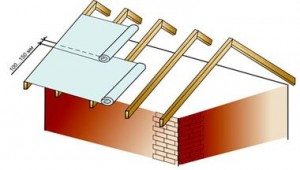

Before starting the installation process, it is necessary to provide the roof with reliable waterproofing. A layer that protects the roof from moisture penetration is laid on the roof structure. After that, the crate is equipped and, directly, the profiled material itself.

Roof waterproofing from corrugated board is carried out depending on the type of roof:

- warm;

- cold.

For a warm roof, a waterproofing membrane is used, which is laid in a horizontal direction, without sagging. For a cold roof, both a waterproofing membrane and a film are used. The arrangement of the film is carried out with sagging.

Attention. When using films with the manufacturer's logo on one side, laying is done with the designation facing out. Reversing the film is unacceptable, in order to avoid the loss of its basic properties.

Insulation laying

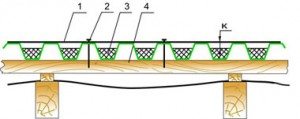

Special attention should be paid to the insulation of corrugated roofing. Together with waterproofing, the heat-insulating layer contributes to the formation of a roofing cake under the profiled sheets.

Again, laying material such as roof insulationdepends on the type of roof. Carrying out the installation of a warm roof, slab and matte heaters are used, without the need to provide a gap between the layer of heat and waterproofing. Laying of materials is carried out between the rafters.

When arranging a cold roof, a ventilated space is created. In order to reduce the formation of condensate, the insulation from the side of the room is covered with a layer of vapor barrier material.

A kind of corrugated roofing + instruction is not only a guide for working with the main coating, but also with insulation.

Advice. If you are laying thermal insulation in several layers, then you need to do this so that the top layer overlaps the seams of the previous material.

Laying corrugated board

When the rafter system is built, the waterproofing is laid, the crate is mounted, you can start laying the profiled sheets.

Roofing from corrugated board + the technology of its device also includes the rules:

- moving on the roof;

- raising the corrugated board to the roof surface;

- anchoring the base material.

To raise materials, there are main points:

- the material is not lifted in windy weather;

- lifting is carried out with the help of a log;

- two people serve the sheet, and one takes it on the roof;

- lift only one sheet at a time.

It is necessary to move along the roof in shoes with soft soles, trying not to step on the wave.

To step into the deflection between the waves, the corrugated board should be laid so that the deflection adjoins the crate. When working with profiled sheets, gloves should be used, since the edge of the material is quite sharp.

Laying of sheets is carried out with an overlap. There is such a pattern: the lower the angle of inclination, the greater the overlap of the material should be.

If you are working on a flat roof, then it is necessary to carry out the installation of the material so that the sheets overlap each other in two corrugations. This technology of installation of corrugated roofing prevents moisture from entering under the roofing.

Fastening sheets and nodes

The fastening of the corrugated board to the base occurs in wave deflections, using self-tapping screws with rubber gaskets. Places of cuts or chips on the profile must be treated with products intended for polymer-coated metal sheets.

When screwing screws on the surface of the sheet, chips are formed. It must be removed so that it does not spoil the sheets, rusting from exposure to precipitation.

In the process of fastening, roofing units made of corrugated board have an important feature. Despite the fact that the process of installing profiled sheets is fast, a lot of time is spent on such places.

Nodes are the places where the corrugated board is combined. If their device is not taken seriously, then it is unlikely that the roof will reliably protect the building from external influences.

The nodes on the roof act as:

- insulating transition elements from one roof surface to another, for example, from horizontal to vertical;

- connection of roofing elements with each other.

Therefore, the joints must be arranged so that there are no gaps that contribute to leakage.

Advice. After completing the full scope of work, once again make sure that the connection of the nodal elements is correct.

Skate device

No less important in the construction of the roof than the nodal elements is the device of the ridge, the implementation of which is an instruction for the installation of roofing corrugated board.

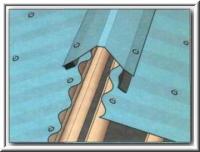

Ridge elements are laid with an overlap of 200 mm, fastened to the upper corrugation using self-tapping screws. Self-tapping screws are selected taking into account the height of the wave of the profiled sheet. When fastening, it is recommended to adhere to a step of 300 mm.

With a slight slope of the roof, it has become important to use a sealant on skates, which makes it possible to resist the ingress of moisture in the oblique direction of precipitation.

When installing the seals, it is advisable to leave a gap between them and the ridge for ventilation.

Attention. It is recommended to start laying the ridge on the side of the roof that is less exposed to rain. For example, if, when your house is located, the east side is exposed to wind loads more often, then it is necessary to start the installation of ridge elements from the west side.

In this article, we tried to outline all the important points of laying corrugated roofing, including thermal and waterproofing. Based on them, it is possible to achieve high-quality performance of all stages of roofing work.

Roofing from corrugated board + video can more clearly show all the processes of installing profiled sheets. Remember that proper installation increases the durability of the coating and roof.

Did the article help you?