Gone are the days when a profiled zinc sheet performed purely utilitarian functions. Basically, fences for industrial zones and construction sites, industrial and temporary buildings were erected from it. Now the various colors of corrugated board make it possible to use it, in addition to the main purpose, for design purposes. How the material is painted, and what it gives - later in the article.

Decking still has a very wide range of applications. From it, as before, they make all sorts of change houses and fences, hangars and production workshops.

But with the development of individual housing construction, as well as with the acquisition of new useful properties by this material, it is increasingly being used for the construction of cottages.

But with the development of individual housing construction, as well as with the acquisition of new useful properties by this material, it is increasingly being used for the construction of cottages.

Moreover, he himself becomes not only a part of the building envelope, but also an element that can enliven the appearance of the house. Since it is possible to use one color of corrugated board for the roof of the building, and for the fence, and sometimes for part of the structure (built-in garage, for example), the material even gains advantages over competitors.

It is unlikely that anyone would think of building a fence, for example, from euro tiles.

The versatility of the material allows you to create a whole ensemble of structures on the estate. Experienced designers, using colored corrugated board, in addition to banal fences and roofs, can arrange, for example:

- Gate with wicket

- Outbuildings

- Sheds

- gazebos

And the list is not limited to this. It is especially pleasant that all this magnificence "on a circle" will cost relatively inexpensively. It is difficult to find a second material with such a unique set of properties.

Manufacturers highlight the following positive aspects of corrugated board:

- Low price (compared to other roofing and fencing materials)

- High manufacturability and speed during installation and ease of processing

- Versatility (possibility of multi-purpose use)

- Service life of 50 years - for an ordinary galvanized sheet, colored corrugated board has a much longer

- Resistant to most aggressive substances contained in the atmosphere and precipitation

- Possibility of installation in any weather conditions - both in terms of humidity and air temperature

- Light weight, resulting in additional savings on materials for load-bearing structures

- The aforementioned aesthetic

A building that enlivens the landscape with a variety of colors of corrugated board

ADVICE! If, when constructing a roof, the direction of laying the sheets is clear, since it should provide a normal drain (for this, there is even a special microcapillary groove at the top of the wave), then you can save on the construction of the fence. Yes, and with some tones of colors, corrugated board even benefits from non-standard orientation in space. The length of a sheet of corrugated board can reach 12 or even 14 m. If it is placed horizontally, it will require a much smaller number of supports, and the amount of work will be reduced significantly.

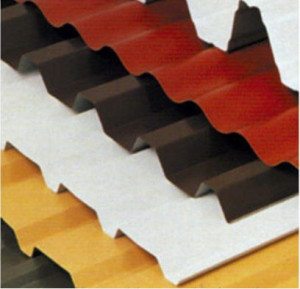

With regard to color, corrugated board has its own classification. Since it is made from a metal strip, the processing with dyes, which not only decorate, but also protect the material, is subjected to raw materials, and not to the finished product.

There are two types of coatings:

- Paintwork (requirements are regulated by GOST 30246-94)

- Polymer - a new class, GOSTs for them have not yet been developed. TUs are mainly used

All coatings can be single or multilayer. The quality of the protective material is determined by the thickness of the final layer of the film, and its qualities: resistance to moisture, chemicals, ultraviolet radiation, mechanical damage.

According to the nature of the coating that gives color, the corrugated board is divided into:

- One-sided - when only the front side of the sheet is painted (outer in a roll). This type of material is used in conditions where only one side of the material is exposed to harmful effects - for example, in a roof

- Double-sided the same - when the same coating is used inside and outside. It is worth using, for example, in the case when the owner wants the fence around the site to be equally good both from the inside and outside

- Double-sided different - when different types, or even types of paint are applied to the inside and outside (for example, polymer and mineral paint). This type of coating is appropriate when an aggressive effect on the material is possible on both sides, but on the one hand, greater aesthetics is required, for example, garage walls

When combined with other materials, it is very convenient that the color range of corrugated board by all manufacturers is classified according to one of the standard color determination systems. It is enough to know what marking, and according to what system one of the materials has - and you can easily match it with another tone on tone.

Important information! The main color systems that exist on the building materials market:

-

RAL (RAL) - German origin, contains 194 colors, the coding looks like this: RAL 840-HR, etc.

-

MONICOLOR (Nova) - developed by the Finnish Tikkurila Oy, had 600 shades until 1992, after which it was expanded until 2024 and received the Nova prefix. The most common classification in the CIS countries

-

NCS is a system developed by the Swedes. Has 1750 standard shades

-

TROX - 65 shades. Used to determine the color of paints and varnishes for wood

However, with such a docking, a small problem may arise. Unlike many modern materials based on polymer compounds, the protective coating of corrugated sheet does not change color over time at all, or changes very little.

The result is the following: initially, say, siding and corrugated board were selected - chocolate color, and almost matched tone on tone.

Several years pass - and nothing has happened to the metal, and the siding looks decrepit against its background.Here it is worth either thinking about the durability of other finishes in advance, or you will have to regularly return color harmony with paint.

A few mounting tips

For any roofing materials from tin, fasteners are very important. And corrugated board is no exception. Rather, it is a clear confirmation of this rule. It is clear that eye-catching spots on the roof or fence will not please anyone.

And - whatever the color of the corrugated board, for it you can always choose fasteners that are in harmony in tone. However, the main thing here is not even aesthetics. Painting will additionally protect the self-tapping screws from harmful atmospheric influences, and equalize their service life with the coating material.

In addition to coloring, attention should be paid to the correct layout. corrugated board fixings. The screws must have a double skirt - a dense rubber gasket is attached to the sheet, creating a reliable but elastic connection, as well as protecting the protective coating and the sheet itself from damage and moisture penetration.

Under the head there should be a self-tapping screw for corrugated board, a metal washer of the same diameter as the gasket. Its task is to increase the area of contact with the roofing material.

Any material is not perfect. So for such a product as corrugated board, color, or rather, the coloring layer, is both a strength and a weakness at the same time.

The protective coating at all stages must be handled carefully - protected from mechanical damage.

They greatly reduce the service life. Therefore, it is not recommended to use a painted profiled sheet for exploited roofs, except to protect it from above with something else additionally.

In general, coated with protective compositions, especially modern composites, the profiled sheet exhibits very high operational qualities - it is strong, reliable, and durable.

And taking into account the achievements of the modern chemical industry, the color scheme decorating the corrugated board allows you to make it a true decoration of any building or suburban area.

Did the article help you?