This article will talk about how the corrugated board is fastened to the wall, roof, ceiling, etc., and what nuances should be taken into account.

This article will talk about how the corrugated board is fastened to the wall, roof, ceiling, etc., and what nuances should be taken into account.

Any modern method of fastening corrugated board, for example, ceiling mount to corrugated board, or fastening to the roof or walls, has a number of its own characteristics.

Fastening methods are distinguished not only according to the type of fastening equipment and technique used (which, in turn, depends on the material from which the base is made - steel or wood), but also depending on how the fastening procedure is performed.

For example, the fastening of corrugated board with self-tapping screws to metal or wooden roofing girders begins to be performed from the lower section of the corrugation.

In this case, special galvanized self-tapping screws should be used, which should be equipped with sealing washers made of neoprene rubber.

Ceiling fastening to corrugated board, as well as fastening to materials such as metal and wood, is carried out using special self-tapping screws for corrugated board, and the price of metal fasteners is often slightly higher than the cost of wood fasteners.

How to fix corrugated board when building a roof

Let's consider fasteners for corrugated roofing, as well as the reasons why it is chosen as a roofing material.

In addition to covering roofs, corrugated board is also used for finishing fences, walls and other building structures, but it is the scheme for attaching corrugated board to the roof that uses a reinforced formula, thanks to which the material can withstand more significant external loads, providing reliable protection for interior spaces.

This also contributes to the spread of corrugated board as a roofing material.

In addition, it should be noted the ease of implementation roofing works with corrugated board, the sheets of which are strong enough at low weight, which ensures ease of handling and does not require reinforcement of the truss system.

All together, the above advantages can significantly facilitate and speed up the construction of the roof.

In the case of corrugated board, fastening to the roof can be made even with a slight slope, which is another advantage of covering the roof with this material: many other roofing materials cannot be laid at a small angle.

Besides, roofing steel galvanized, manufactured using modern technologies, has good protection against corrosion, which can significantly increase their service life.

The installation of corrugated board on the roof, which does not require various additional devices, such as a v-shaped mount for corrugated board, can be done independently even by a person who does not have any building skills.

The material is quite easy to handle, easy to cut and fasten with bolts or self-tapping screws.

Important: an important positive characteristic of corrugated board is the possibility of its installation in any weather, since it is not significantly affected by high or low ambient temperatures.

The main points of fixing corrugated board on the roof:

- First of all, the material is spread out in the correct order and the required position, while the dependence of the overlapping of the sheets on the angle of the roof should be taken into account. This dependence is quite simple, it includes several numbers. The overlap of the sheets is inversely proportional to the slope of the roof. If the slope does not exceed 15 °, the largest overlap is selected, which is about 20 centimeters.In the case when the slope is more than 30 degrees, the overlap is reduced to 10-15 centimeters. Critically small roof pitch angles (10 degrees and below) require additional sealing of all overlaps.

- The technology of attaching corrugated board to the roof also includes the manufacture of lathing, the size of which also directly depends on the slope of the roof, as well as on the size of the corrugation of the corrugated sheet. An increase in the height of the corrugation or an increase in the angle of inclination allows you to increase the step of the crate. In addition, the angle of the roof slope and the height of the roof influence the number of waves used in the floor. In the case of a small wave height and a small angle of inclination, at least two waves should be used in overlapping.

- After such preparatory processes as the manufacture of the crate and the marking of the sheets are completed, it is possible to directly fasten the corrugated board. The main fasteners for corrugated board, which allows you to perform the most high-quality and efficient fastening, are special roofing screws, which are equipped with a rather convenient cap that allows twisting with both electric and mechanical tools. At the end of such a self-tapping screw there is a drill that allows you to make a high-quality neat hole without causing damage to the sheet. Under the hat there is insulation, and on the hat there is a special coating that protects the entire attachment point from corrosion, moisture and sunlight, significantly increasing the life of the coating.

- When installing corrugated board, it should be remembered that the bolts are screwed only into the cavities of the sheets. Self-tapping screws for the ridge and for the main part of the roof differ in length, which is slightly longer for ridge screws.When manually screwing screws, it is necessary to correctly calculate the force, the excess of which can lead to damage to the insulation, as a result of which the overall protective function of the roof will be impaired.

- If the length of the sheets allows you to completely cover the roof slope, they are simply fixed with self-tapping screws parallel to the eaves. When ordering sheets of corrugated board, you should remember about the margin for overhang, which is about 40 millimeters. If the length of the sheet is less than the length of the slope, laying is carried out in several rows, starting from the bottom and moving up, laying each next row with an overlap of about 20 cm.

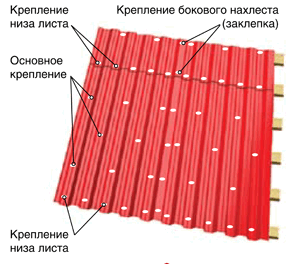

So, fasteners with a size of 4.8x28 ... 40 are shown in the lower corrugation. The fastening of the ridge is carried out in the upper corrugation of the sheet.

The fastening is recommended to be placed in the center, and the length of the fastening of the ridge depends directly on the height of the corrugated sheet wave.

When fastening profiled sheets to the crate, 6-7 self-tapping screws per square meter of the covered roof are most often used. Between themselves, the sheets are connected using special rivets, the color of which matches the color of the coating.

Installation of corrugated board in the construction of walls and enclosing structures

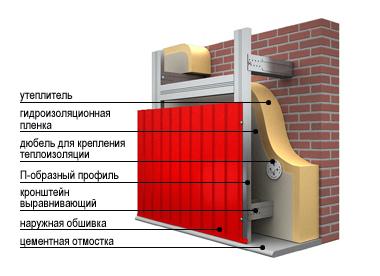

To ensure the effectiveness and reliability of the base under the corrugated board, it is necessary to provide in advance measures to protect against dampness and condensate formed during operation.

Both "C" and "Z" profiles, as well as metal elements of the crate can be used as runs. If wooden veins are used, they should be treated with special compounds to prevent rotting and damage to the wood.

The scheme, according to which the corrugated board is attached, should not come into contact with concrete and similar bases, as practice shows.

The planning of the attachment points of the corrugated board to the battens of the lathing is carried out at such a distance, which is determined by the brand of the profile and various conditions for future operation.

The first step is to install the first source sheet strictly vertically, checking the correct installation with a level.

The order of fastening the sheets is usually chosen in the direction from right to left, and along the lower edge there is an ebb, designed to protect the lower room from precipitation.

Sheet fastening can be both horizontal and vertical. Fastening sheets of corrugated board is carried out using self-tapping screws, starting from the bottom edge and moving up. In this case, the distance between the supporting structure and the self-tapping screws should be kept as small as possible.

Before proceeding with the installation of the following sheets, they should be carefully fixed, while eliminating overlap. The overlap is fixed at the very end of the work.

With horizontal installation of corrugated board sheets, the role of attachment points is most often played by elements such as corners and dividing profiles with hidden fastening.

Important: the installation of such elements should be carried out before the installation of the coating itself.

In the construction of fences and fences from corrugated board, a method similar to the installation of facade wall coverings is used. The classification of the fence corrugated board corresponds to the classification of the wall.

The only significant difference lies in the bearing base, which can be made in the form of ordinary poles or veined poles.

Ceiling mounting corrugated board

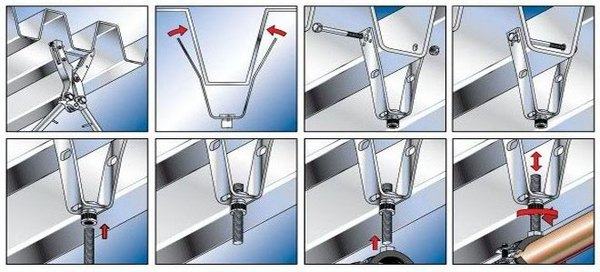

To carry out the laying of various communications, modern building technologies provide for a V-shaped fastening for corrugated board in the form of a bracket (see figure), which allows fastening under ceilings made of this material.

The V-shaped fastening to the corrugated board is quite easily adjusted to various trapezoidal profiles, for this it is necessary to find out and mark the bend points in advance.

Next, the bracket is fixed with the help of pins, the thread for which is available in the holes located on the sides of the mounting.

That's all I wanted to talk about the main methods of fastening corrugated board. Compliance with the recommendations given in this article, and the correct selection of material will make it possible to cover walls or roofs with corrugated board with high quality and reliability.

Did the article help you?