This article is devoted to a detailed description of the assembly process of this roofing. To facilitate your task, we also place a detailed video instruction for the installation of metal tiles.

This article is devoted to a detailed description of the assembly process of this roofing. To facilitate your task, we also place a detailed video instruction for the installation of metal tiles.

- General recommendations

- Handling of metal tiles

- Measurement and calculation of sheets

- Flooring waterproofing material

- Arrangement of ventilation of the crate and flooring

- Lathing installation

- Laying sheets of metal

- Material fixing

- Valley processing

- About through exits to the roof

- Snow retention

- About the seal

- Fastening of the gable and ridge slats

- Docking and cornice strips

General recommendations

- To achieve a high-quality result, make sure that the roof surface of the building is even before work. To do this, check if it has the correct shape and dimensions. Correct any defects as necessary.

- For this purpose, it is necessary to measure from corner to corner of the diagonal of the slopes. When they do not match in length, this means that the roof is skewed. If it cannot be straightened, then lay the roofing material in such a way that the lower edge of the lathing coincides with the overhang line of the tiles. End warp can be closed additional elements of the roof .

- Minimum roof pitch should be 14º if the length of the slopes is 7 m.

- Any rigid topcoat that has been laid early must be completely removed.

- Hooks for fixing the gutters of the drain must be installed even before the start of roofing work and fasten them only with galvanized screws.

- Individual elements must be mounted in sequence from bottom to top.

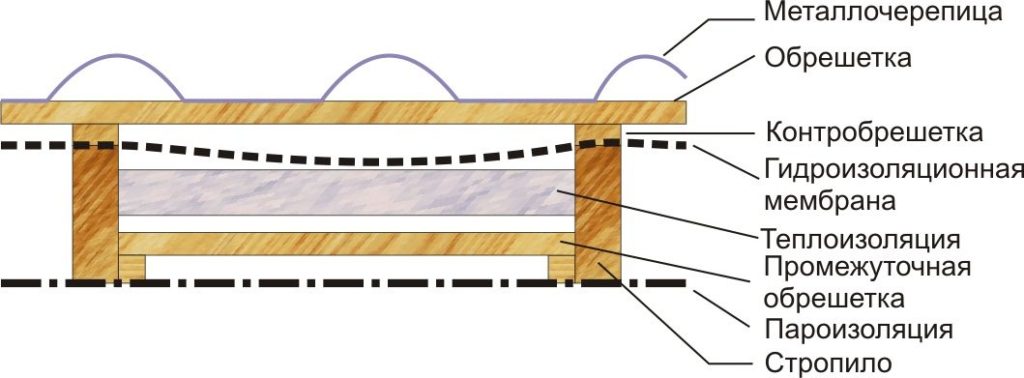

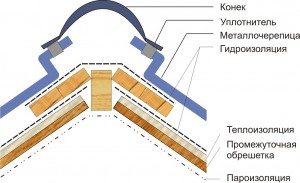

- To prevent the accumulation of moisture and its seepage into the top layer of thermal insulation, you need to use a waterproofing film.

- To protect the insulation from vapors emanating from the interior, it is recommended to use a vapor barrier.

The need for ventilation of the under-roof space, i.e. – the organization of ventilation depends on the following factors:

- Degrees of humidity of external and internal air;

- Temperature differences between roof structures and outdoor air;

- The level of tightness of the roof and its base;

- The thickness of the thermal insulation layer.

Note! Recommendations for the installation of metal tiles indicate that the waterproofing carpet must be laid, going from the eaves to the ridge and overlapping.Under the ridge, it is necessary to make a ventilation gap of at least 5 cm so that moisture evaporates freely. This is especially important if the attic is warm. The crate must be mounted in such a way that the air passes without problems from the cornice to the roof ridge.

Ventilation openings must be equipped on the highest section of the roof.

Warehouses, as well as unheated attics, must be ventilated through the end windows. In especially important rooms, ventilation must be forced.

Handling of metal tiles

- Loading and unloading of roofing material must be done carefully so as not to expose its surface to mechanical damage.

- Carry out the transfer and lifting of the metal tile only by grasping its edges along the length and always in tight gloves.

- Sheets can be cut with a hacksaw and metal shears or an electric saw with carbide teeth.

- Cut edges, as well as found chips and damage to the protective layer, must be painted over with a special paint to protect the metal from corrosion.

- It is strictly forbidden to use an angle grinder (grinder) with abrasive discs for cutting sheets.

- Metal shavings formed during roofing should be carefully removed with a soft brush. If the surface of the coating has been contaminated, then wash off this dirt with a mild detergent composition. Do not use cleaning products containing abrasives, as well as solvent-based substances.

- To clean ice and snow from a metal roof, it is strongly not recommended to use a crowbar, scraper or snow shovel. This will cause damage to the coating and significantly reduce its service life.

- When you install metal tiles with your own hands - the video material shows this, wear shoes with soft soles to walk on profiled sheets. Step only into the deflections of the waves, into the areas under which the bars of the crate are located. It is undesirable to walk on the ridges of the profiles - this will lead to deformation of thin sheets.

Measurement and calculation of sheets

The length of the sheets is usually taken as the length of the slopes. When they have protrusions, then the pitch must also be taken into account (with 40 cm being type No. 1, and 35 cm being types No. 2 and No. 3), so that the patterns of the tiles coincide in the areas of transition to sheets with a different length.

Note! If the slope has a stepped shape or its length is more than 6 meters, then sheets of different lengths can be used for roofing. When laying two or more sheets on a slope, consider the overlap length of 13 cm. If your case is exceptional, inform the manufacturer of the additional overlap when ordering tiles.

Sheet type 1/1025 (usable width in millimeters) in some of the lengths has an additional transverse bend. This simplifies installation and also prevents the edge of the sheet from spreading.

Take this circumstance into account when ordering tiles of this type, which have different lengths and are intended for the same slope.

When the roof has a complex configuration, or you decide to use sheets with a usable width of 1025mm, it is necessary to carefully measure the area of \u200b\u200bthe roof.

You can calculate the number of sheets in this way: the length of the cornice is divided by the useful width of the material and rounded up to the full unit (multiplied by the number of slopes).In this case, the useful width of the last of the slope sheets is equal to its full width.

When measuring a hipped roof, please note that the cut profiled sheet cannot be used on the opposite slope, due to the pattern, which has a transverse corrugation.

Flooring waterproofing material

As our video shows - a metal tile: its installation must be preceded by a flooring of a waterproofing film. It will prevent condensation from settling on the roof structures.

Spread the panels with an overlap, move in the direction of the ridge, and start from the place of the cornice overhang.

You can attach the film to the rafters using a construction stapler. The overlap of the panels should be 15cm.

Note! It is not necessary to pull the material between the rafters too much. Leave about 2/3cm of free-hanging camber. On both sides of the tent ridge, approximately 15 cm of the film should be stretched into the bend.

Lay waterproofing in the area of the eaves, so that the accumulated condensate does not fall on the wall structures, and the air flow passes without problems to the upper sections of the flooring.

In the area of the gable overhang, lay the film at a distance of 20 cm from the extreme point of the wall structures.

The crate must be nailed over the waterproofing layer. At a minimum, the thickness of its boards should be 3.2 × 5 cm.

Arrangement of ventilation of the crate and flooring

On top of the waterproofing film, along the rafters, nail the ventilation slats (counter-batten) so that the air flow from the cornice can freely pass between the decking and the roofing material.

Humid air must be removed from the eaves through the ridge ventilation element or.If the skate has a short structure - up to 10 meters, then the air flow must go through the shaped skate, through its end.

The section of the eaves overhang must ensure unhindered passage of air flow in the direction from the eaves to the under-roof ventilation gap. Further, the air should leave through the wind windows of the attic.

Our instructions for installing metal tiles recommend that in structures in which the heat-insulating material is laid in the direction along the slopes up to the ridge, the waterproofing should not be stretched up to the ridge and a gap of about 10 cm should be left uncovered around it.

The ingress of moisture into the building, in this case, should be prevented by a ventilated seal of a special additional element, for example, a Top-Roll ridge or a special ventilation ridge.

To prevent water from penetrating the crate, attach a strip of waterproofing material under the ridge. On gable and hipped four-pitched roofs, the ventilation ridge is placed in the same way.

The lower ventilation gap (under the flooring), throughout the entire length of the structure, must be equal to at least 10 cm.

Lathing installation

Below are the basic rules for assembling the crate:

- When choosing the thickness of the boards for it, take into account the height of the tile profiles and the length of the fasteners corresponding to it (if the fastening will occur from the top of the profile waves).

- At a minimum, the cross section of the boards of the structure should be 3.2 × 10 cm.

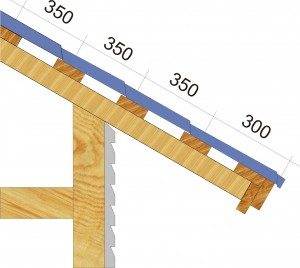

- The board that goes to the eaves should be thicker than the rest. If you collect shaped tiles, types 2 and 3, then 1 cm thicker, if sheets, type 1, then 1.5 cm.

- The step of mounting the boards of the crate (for shaped roofing material) must be a multiple of the dimensions of the sheets.

- Attach the structure to the rafters with hot-dip galvanized nails measuring 2.8×75mm. Their consumption is 2 pieces per 1 cross.

Note! As the video “installation of metal tiles: instruction-video” shows, the ridge should not be nailed, it is necessary to leave a sufficient ventilation gap.

As necessary, install additional support bars and boards for through exits - for a fire hatch, ventilation truss, chimney, etc.

When mounting two or more sheets, use a beam under the seam.

Laying sheets of metal

- When working, move carefully over the tiles, because they may not withstand heavy loads. Walking along the profile sheets, step on the crate: along - into the deflections of the waves, across - on the folds of the profiles.

- It should be borne in mind that when assembling the coating, the capillary grooves of the sheets must be covered with the sheets following them.

- You can start laying the material both left / right, and vice versa. When installing the coating from the right edge, the edge of the next sheet should be placed under the last of the waves of the previous sheet (that is, the capillary groove is located on the wave of its right edge). This simplifies assembly and prevents the last of the sheets from slipping due to its transverse corrugation.

- Place the material along the cornice line so that it protrudes from it by 4 / 4.5 cm.

- Start work by making the first of the sheets with one self-tapping screw, in the middle (near the ridge), in the deflection of the wave.

- Next, lay the second metal tile. Fasten the overlap with a screw along the top of the wave, under the first of its transverse folds.Make sure that all cross folds fit properly and that the bottom edge forms a straight line.

- Fix both sheets overlapping each other with self-tapping screws, under each of the transverse folds.

- Fasten 3/4 sheets together in a similar way, then align their bottom edge with a construction cord along the cornice line.

- An important note on how to join sheets of metal tiles: only by doing this, you can finally attach the metal to the crate.

- Carry out the laying of subsequent sheets by attaching the element first to the previous sheet and only then to the crate.

Material fixing

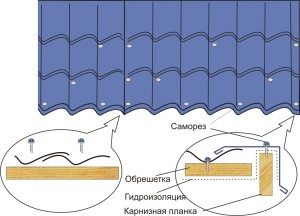

Desirable sizes of self-tapping screws: 4.8×50 mm, 4.8×65 mm or 4.8×80 mm if fastening takes place along the upper part of the wave. Screws with dimensions of 4.8 × 28 mm are used when fixing sheets along the bottom of the wave, as well as at cornices, in overlaps and for fastening all planks.

When working, it is strongly recommended to use screws that have seals made of EPDM rubber.

You should not use nails, because screws are twice as reliable when fastening.

Note! Another tip on how to properly screw the metal tile: in order not to leave dents on the coating, do not tighten the screws too tightly. To screw them in, it is best to use an electric drill that has smooth speed control and reverse.

The average consumption of self-tapping screws during operation is 6 pieces per 1 m² of coating.

Valley processing

First, let's talk about the usual internal groove. Its V-shaped bar is mounted according to the following scheme:

- Start the installation by laying the waterproofing film along the groove and fasten it to the rafters. Only then the waterproofing is laid over the area of the entire roof.

- Lay the ventilation bars, with a section of 3.2 × 5 cm, on the slope, while leaving about 5 cm to the support node.

- Wooden counter-lattice under the metal tile start knocking down the grooves from this support node, from the gap left, using boards with a section of 3.2 × 10 cm.

- Then mount the crate for adjacent slopes with a step that will match the size of the tiles.

- Fix with several self-tapping screws from the cornice in the areas where the groove adjoins the downed crate. The overlap of the planks under the groove should be at least 20 cm. Seal the seams with sealant.

- Next, screw the sheets to the mounted crate. Do not forget to lay the seal between them and the groove strips.

Important information on how the metal roof tile is laid: the gap between the edges of the profiled sheets (near the groove) should be about 20 cm.

Now we should talk about the device of the internal groove in the areas of junction of the main slopes and protruding structures.

The installation rules are as follows:

- Position the profiled sheet from the cornice and along the main slope, so that its upper edge is 40 cm above the lower edge of the groove.

- Align the edge of this groove with the eaves of the slope adjoining it. Next, fix the metal with self-tapping screws at the junction points of the additional element to the crate. The wing of the groove, which will lie on the main slope, must be brought onto the previously mounted cover sheet.

- And the last, how the metal tile-valley is mounted.Lay the profiled sheets of slopes, not forgetting to draw a groove line.

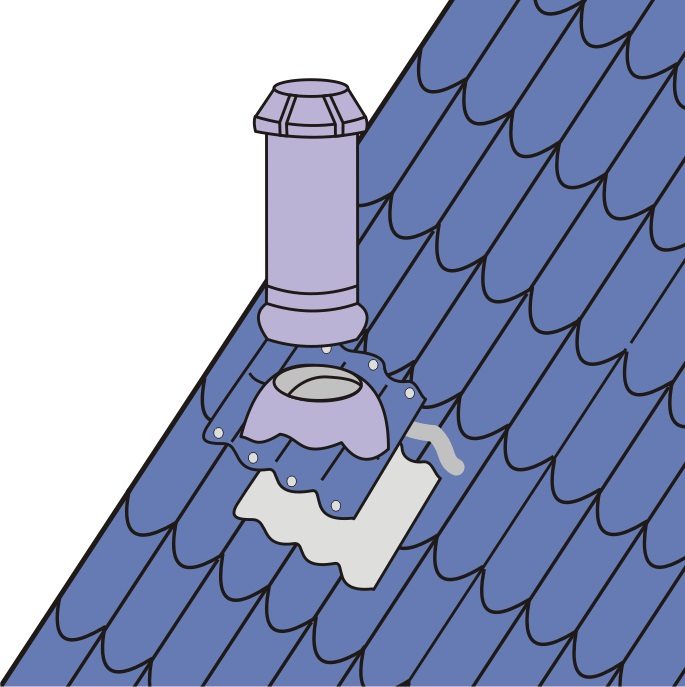

About through exits to the roof

Additional elements designed for through exits to the roof are made of durable types of plastic. At the same time, their color and shape must be selected in full accordance with those of metal tiles.

The installation of these parts is simplified as much as possible. It is almost impossible to break the general pattern of the roofing.

The supplied thru-lead kits always include detailed installation instructions. All emerging gaps and cracks between the additional element and the roofing must be carefully sealed. To do this, you can use standard building moisture-resistant sealing compounds.

Sewer hoods and ventilation pipes are fastened with passage elements. Mounting the fire hatch must be carried out according to the instructions attached to it.

Advice! When metal tiles are being installed, the video instruction recommends installing through exits as close as possible to the ridge or upper eaves. Around the ventilation lance / pipe, fire hatch, support bars are installed and, as necessary, additional boards (solid wooden flooring). All emerging joints must be carefully sealed.

The overlap of the bases of the ventilation lance and the fire hatch with the roof sheets must be done in the same way as between the elements of the coating.

The set of through outlets (ventilation system outlets, VILPE fans, air cleaners, sewage) includes a seal, a base with a seal, as well as a seal for roof penetration made of weather-resistant EPDM rubber.

The instructions for the additional element contain recommendations for their installation.

It should be borne in mind that increased snow loads on the output should not be allowed. Snow should be removed as needed. If the gap from the ridge to the exit is more than 1 meter, it is advisable to place a snow catcher above it.

Snow retention

- For greater safety of the roof operation, it is recommended to install snow catchers in areas of possible snow masses.

- These additional elements are placed in place of the load-bearing structures of the wall.

- Before laying the sheets of metal, lay along the slope, in parallel, additional support bars or boards, for example 5x10cm, to fasten the base of the snow catcher.

- Screw the four mounting bases of the element to the support bar. Mount them 75cm apart along the bottom of the wave, using 8mm screws or bolts with a washer.

- Lay a 3×30 sealing tape between the roofing sheet and the fixing base.

- Attach oval or round snow catcher tubes (2 pieces per set) to the bases and fix their edges with 0.8x3.5cm remotes.

About the seal

For shaped sheets of metal tiles, the smallest angle of inclination is 1:4, for trapezoidal analogues - 1:7. When using these coatings on flat roofs, when the sounded slopes are less than the recommended values, it is desirable to compact vertical and horizontal overlaps.

Seals are recommended to be placed under the ridge, which is mounted parallel to the eaves, as well as on skates that are placed at an angle. In addition, seals must also be used when installing valleys.

Fasten the sealing elements with galvanized nails.After that, you can put the ridge bar.

Fastening of the gable and ridge slats

Next, about how to properly mount the metal tile.

- Fix the gable plank on the board, just above the crate - to the height of the sheet. Do this with roofing screws, in increments of about 80cm. The overlap of the planks should be approximately 10cm.

- Before installing the ridge shaped strip, rivet the end cap. The overlap of these planks should be 13 cm, for smooth analogues - 10 cm.

- Connect with screws, 4.8 × 28 mm in size, along the edge of 3/4 of the plank between themselves and align in the direction of the ridge.

- Lay the sealant between the plank and the roofing sheet.

- Screw the ridge strip with self-tapping screws through the seal to the tiles along the top of every second of the waves. If the skate is adjacent to the slope, cut the end of the bar under it and place it close under the sheet.

- A self-adhesive sealant can be used under the ridge shaped strip. Before installing it, fasten an additional plank on the crests of the rafters, for mounting the seal, so that the edge of the board protrudes slightly beyond the edges of the covering sheets. Lay a sealant on top of the board and fix it with rivets or nails to the ridge plank. Remove the protective film from the edges of the self-adhesive seal and press them into the shape of the profiled sheet.

- You can buy end caps for the ridge shaped strip, as well as ends for a hipped roof, T- and Y-shaped ridge additional elements that can be fastened under the ridge with screws.

Docking and cornice strips

We continue to describe the installation: metal tile - a video about adjoining the wall can help you understand this issue more thoroughly.

At material interfaces with vertical surfaces (walls, parapets, pipes, etc.), fasten the appropriate strips using screws. Use a self-adhesive sealant between the cover sheet and the additional element.

The docking bar must be bent under the slope of the roof and fastened to the sheets along the top of every second of the waves. If the material is trapezoidal, then the fastening step should be 40 cm.

The wall edge of the plank must remain under the wall cladding. When joining with a brick or stone wall, this edge of the additional element must be brought into the "otter" and sealed with a special sealing compound. Be sure to ensure that there is sufficient ventilation at the junction of the roof and wall.

Observe the overlapping of the planks along their length of 10 cm.

To additionally seal these adjoining elements, use construction silicone sealant. Equip chimney linings with smooth sheets that have the same color as the tiles

The cornice strip directs the flow of water into the gutter, and also prevents it from getting on the cornice boards. As the installation instructions for metal tiles show - a video lesson, before installing its sheets, it is necessary to attach the cornice strip to the bottom of the crate with galvanized nails.

The fastening step should be 30cm. Overlap the planks on top of each other by 5 cm. You can also lay a sealant between them and the tiles.

Did the article help you?