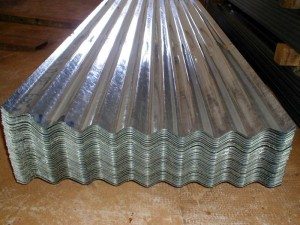

Recently, galvanized roofing steel has been very popular - the state standard of which is an approved standard that requires mandatory compliance.

Recently, galvanized roofing steel has been very popular - the state standard of which is an approved standard that requires mandatory compliance.

- This material has a relatively low cost.

- The material has a low weight, which is very convenient when constructing a roof that has a complex geometric shape. Even the GOST for galvanized steel roofing contains a provision marking this point. Also, such steel can be used for the construction of valleys, cornice overhangs, wall gutters, gutters, roof drain pipes and many other elements.

GOST roofing steel notes that such material must be coated on both sides with a layer of zinc, which serves as protection against corrosion.If the steel is not coated with zinc, then its service life will be very short, as it is subject to corrosion.

Therefore, as a roofing material, non-galvanized steel is practically not used at present.

As roofing material using hot dip galvanized cold rolled steel.

It is obtained as a result of a complex and continuous process. This material is based on cold-rolled coiled steel.

First, the steel is cleaned, then annealed and placed in a bath of zinc melt, where galvanized roofing steel is obtained: the state standard is fully observed.

To your attention! Most often, steel with a thickness of 0.5 mm is used for the manufacture of roofing.

True, metal tiles are also found on the construction market, which are made of steel with a thickness of 0.4 mm.

It requires careful handling during installation, which is not surprising, because the metal tile, not roofing galvanized steel - the guest of which contains completely different requirements.

Tip! As for the slopes, gable overhangs, grooves and drainpipes, it is better to use steel with a thickness of 0.6 mm.

There is another roofing material that is used for roofing - Aluzinc. It is a thin steel sheet, which is not protected by pure zinc, but by an alloy of zinc and aluminum.

Sheet steel quality:

- There are alloy and carbon steels, which differ in chemical composition. At the same time, GOST for roofing steel includes requirements for both of these types.Carbon steels, according to their purpose and quality, are divided into steels, which usually have quality, instrumental and constructive.

- Carbon steel of ordinary quality is obtained by fusing iron and carbon. Most often, galvanized roofing is made of St.3 carbon steel, which is used for various building elements, although it is not the best option for roofing.

- Steels with improved physical and mechanical properties have one or more special elements in their composition, and are called alloyed. Depending on the various additives present in alloyed steels, they are classified as high-alloyed, medium-alloyed and low-alloyed.

Galvanized steel roofing is most often made of low-alloy steel, which contains less than 2.5% alloying substances.

Medium and high alloy steels are used for the manufacture of structures that must have high corrosion resistance, and GOST - galvanized roofing steel does not include this parameter.

Purpose of steels

Depending on the sphere in which steel will be used, it is divided into:

- ordinary,

- quality,

- high quality

- especially high quality.

They differ in the amount of harmful impurities they contain, such as sulfur, the presence of which reduces the mechanical strength when heated; phosphorus, which increases brittleness with decreasing temperature, as well as the quantitative content of non-metallic particles.

roofing steel

Depending on the thickness of the sheet, galvanized roofing steel is divided into:

- thick sheet (sheet thickness exceeds 0.4 mm)

- thin sheet (sheet thickness does not exceed 0.39 mm).

For the device of the roof, roofing steel is used: the state standard at the same time reflects the requirements for its thickness equal to 0.45-0.50 mm.

It also contains requirements for cornice and gable parts, grooves and downpipe parts, the steel thickness for which should be 0.63 or 0.70 mm.

As a rule, steel sheets are produced with a length of 2 meters and a width of 50-75 cm.

In order to extend the life of a galvanized roof, you need to use special anti-corrosion primers that will protect it from natural destruction.

When properly installed, galvanized roofing is resistant to adverse effects. In addition, galvanizing is convenient to mount, and it is not expensive.

True, having made a roof from such material, you need to be prepared for strong noise during rain and the obsessive rattle of steel in the wind. In the event that you are not ready for this, then galvanized steel roofing is not recommended, as you will have to replace it soon.

Whatever steel is used, sooner or later the galvanized roof will still need to be repaired.

In order to postpone this unpleasant moment, you need to take care of the roof. It is advisable to start doing this from the moment of its device. It is recommended to immediately paint the steel, which will extend its service life.

It should be noted that painting galvanized metal is not an unambiguous operation. cottage roof repair.

The reason for this lies in the fact that galvanized iron has a passive surface, which means that it is necessary to use a special paint for it, which has greater adhesion and elasticity.

For these purposes, oil and alkyd paints are not suitable. When zinc and alkyd paint interact, oxidation will occur, which will lead to a loss of adhesive properties.

As a result, expensive paint will “peel off” the coating. And such a coating will serve no longer than one season.

Tip! Acrylic primer-enamel is best suited for these purposes, which will last a long time. True, such paint is not cheap, but in any case it will be cheaper than replacing the roof. Yes, and the painted roof looks more elegant than just galvanized.

Before you start painting, you need to check roof covering. If rusted surfaces appear, they must be cleaned or replaced. In the event that replacement cannot be carried out, then the hole will need to be patched.

It is also necessary to clean the roof of dirt and old paint, then wash, degrease and dry. The paint can be applied with a brush, roller or spray gun.

In the event that cracks have formed on the roof, they will have to be soldered. To do this, clean the joints of the sheets from rust with sandpaper, and then tightly fit the sheets to be joined.

Wipe the surface with a brush dipped in zinc chloride. In order to solder the surfaces, heat the soldering iron, after rubbing it with ammonia. After that, apply solder to the ends of the sheets. When everything cools down, remove excess solder.

To your attention! It is better not to prepare zinc chloride yourself, as an explosion may occur as a result of improper mixing. It is better to entrust this to specialists who know the state standard - roofing steel will definitely be cleaned with high quality. Yes, you don't need burns.Well, or get a ready-made weather vane.

To not have to do roof repair it is better to avoid mechanical damage, especially during installation. It is even better to use special roofing screws that have an elastic silicone gasket under the hat.

They also have a sealing hole for precipitation. In addition, you must not forget to paint the roof, and then it will serve you as long as the house will stand.

They also have a sealing hole for precipitation. In addition, you must not forget to paint the roof, and then it will serve you as long as the house will stand.

Did the article help you?