The main part of the house is the roof, placed on the outer, upper surface. It is she who, day after day, directly perceives the impact of all atmospheric phenomena - wind, precipitation, temperature, insolation and protects the house from the influence of these factors. Roofing is carried out using various materials. In this article, we will talk about such an independent material as roofing mastic, and the features of the installation and repair of a roof with this coating.

The main part of the house is the roof, placed on the outer, upper surface. It is she who, day after day, directly perceives the impact of all atmospheric phenomena - wind, precipitation, temperature, insolation and protects the house from the influence of these factors. Roofing is carried out using various materials. In this article, we will talk about such an independent material as roofing mastic, and the features of the installation and repair of a roof with this coating.

Covering the roof with mastic

Mastic roofing is carried out without the use of rolled materials, and mastics are used as an independent roofing.A prerequisite for such a roof is a uniform distribution of material over the roof surface.

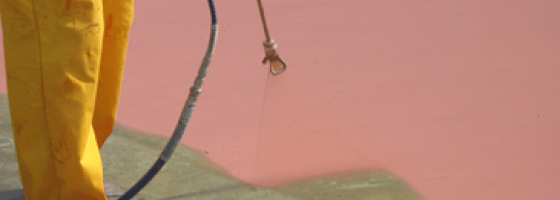

The mastic is applied manually or with a sprayer. The next layer is applied after the previous one has cured.

For better strength, mastic roofs are reinforced with a mesh of durable fiberglass or fiberglass panels. These materials have high mechanical strength.

The basis for the roof can serve as a cement-sand screed or reinforced concrete slabs. At the junction of the elements of the roof with vertical walls, the sides of the cement mortar are installed.

Before applying the mastic, the sides and the base are to be primed.

A mastic carpet is created on the roof in 2-3 layers.

The cornice overhang, ridge, groove and valley at the junction with the roof are reinforced with an additional layer:

- strengthening the ridge is carried out with a layer of mastic 60 cm wide, reinforced with fiberglass or fiberglass;

- strengthening of the valley, cornice overhang and groove is carried out in two layers with reinforcement.

Basically, the number of reinforcing and mastic layers depends on the angle of inclination of the slope:

- installation of mastic roofs with a slope of 10% - mastic coating in three layers, reinforcing pads - in two layers, an additional protective, gravel layer is arranged;

- slope 15% - mastic carpet and reinforcement is carried out in two layers with the top layer coated with gravel;

- slope 25% - mastic coating in three layers, reinforcement in two, the top layer is covered with paint.

Roof elements such as a valley, a ridge, a cornice overhang are strengthened until the main mastic carpet is applied.

The joints of the roof with protruding vertical parts and walls are strengthened after covering the base of the roof. The top is covered with a gravel layer. The reinforcement thickness is 8 mm.

Attention. Reinforcing mastic increases the strength of the coating, but reduces its elasticity.

Types and properties of mastics

Roofing mastics are represented by a wide classification range:

- polymeric;

- bitumen-polymer;

- bitumen-latex;

- bituminous.

They have the following properties:

- elasticity;

- light weight;

- high strength;

- resistance to solar radiation;

- stability when used in an aggressive environment.

To change the properties of the mastic in conditions of a certain need, the addition of various fillers that affect the elasticity and strength of the material is used.

In this regard, mastics can be used on various surfaces:

- concrete;

- steel;

- ruberoid.

This material can act as an independent coating or adhesive when installing roofs using rolled materials. Roof repair is also used.

Mastics differ in the number of components that make up their composition: one-component and two-component. A single-component mastic is based on a solvent. When it evaporates, the composition on the roof acquires a solid, elastic state. Such mastics are available in ready-to-apply form.

An example of such a material is Slavyanka roofing mastic, the scope of which is quite wide:

- coating of new roofs;

- repair work on old coatings;

- arrangement of junctions of shaped elements, horizontal and vertical surfaces;

- sealing joints and folds;

- protection of the roof surface from environmental influences;

- roof waterproofing.

This mastic belongs to the bitumen-polymer coating. It can be applied under pressure or by hand. The thickness of one layer is 2 mm.

It can also be applied by pouring, followed by an even distribution over the entire surface. Mastic resists moisture after one hour after application.

Two-component mastics at release are represented by two compositions. When applied, they must be mixed, which allows you to change the properties of the material according to real, building requirements.

Depending on the application, cold and hot mastics are distinguished.

Hot application is a more labor-intensive process. According to a survey of consumers working with mastic coatings, it turned out that cold roofing mastic is more convenient to use.

Bituminous mastic

Cold-applied mastics include bituminous mastics, which are roofing insulating material that protects the roof surface from radiation and precipitation.

Bituminous mastics include in their composition a mixture of petroleum bitumen and various fillers that reduce the brittleness of the material, increase its strength, elasticity and heat resistance.

Bituminous mastics in their mixture may contain various components.

In this regard, they can be divided into the following groups:

- bitumen-polymer;

- rubber-bitumen;

- bituminous emulsion.

Bitumast roofing mastic is a high-quality bitumen-polymer coating.

This material is used:

- for the repair of almost all types of roofing;

- waterproofing surfaces;

- for anticorrosive treatment of metal roofs.

It has a rather thick consistency, so it is suitable for sealing horizontal cracks and seams. Mastic of this brand does not contain toxic solvents.

Bituminous mastics prevent the penetration of moisture under the roof and the growth of plants in the roof sheet. When applied, the surface must be clean and dry.

Attention. The shelf life of the above mastic is 24 months. Whereas other mastics, produced in the finished state, are stored for no more than a year.

Cold mastics

If we are already talking about bituminous mastic, then I would like to dwell in more detail on what cold roofing mastic is.

This roof material prepared with a dilute binder. It is suitable both for roof covering, and for vapor barrier or gluing of rolled materials.

To dilute cold mastics to the desired consistency, diluents of organic origin (volatile and non-volatile) are used.

Volatile diluents, in turn, are divided into:

- aviation and motor gasoline;

- White Spirit;

- lighting kerosene.

Non-volatile diluents include:

- lubricating, transformer and machine oil;

- liquid bitumen;

- fuel oil

Many cold mastics are produced on the basis of bituminous pastes with the addition of antiseptics and mineral fillers. In this case, water is used as the diluent.

Attention. Such mastics are not suitable for gluing rolled materials on the roof, as bubbles and swelling form under the rolled roofing mat as a result of evaporation of water.Therefore, mastics based on bituminous paste are used when carrying out repair work on the roof to seal cracks and seams and to apply a new layer to a clean surface.

Production work

Before use, the cold roofing mastic is thoroughly mixed. In accordance with the requirements of the application, it is diluted with various solvents.

It is possible to work with roofing mastic in the conditions of the lowered temperatures. To do this, it is necessary to warm it indoors at a temperature of over 15 degrees for 24 hours.

Before applying the mastic coating, ice, snow, dirt, deformation coating should be removed from the surface. The porous surface of the roof before applying the bituminous mastic is treated with bituminous primers.

If the manufacturer did not indicate in the technical specifications the possibility of applying the mastic on a wet surface, then it is necessary to dry the coating area before using it.

Mastic is applied with a brush or spatula, when poured it is leveled with a mop.

Permissible measures for the use of this material:

- lack of precipitation;

- temperature over minus 5 degrees.

Storage of mastic is carried out in a closed container. According to the conditions of the manufacturers, direct sunlight, storage near sources of fire, and exposure to moisture are not allowed.

Hot bituminous roofing mastics are flammable materials, so work with them is carried out in the open air, away from the source of fire. When working, wear protective clothing to avoid skin contact with mastic.

Roof decking on composite roofs is often exposed to water vapor rising up and forcing the roofing "work" to pull away.

Roof mastic, at the same time, due to the ability to interlock with the roofing panel, it ensures its reliability, tightness and strength. The installation of roofing systems, providing waterproofing, laying rolled coating, sealing roofing deformations with mastic becomes much easier.

Did the article help you?