Soft roofing has found wide application in individual construction. There are many reasons for this, one of which is the relative ease of installation. In this article, we will try to get acquainted with the most common materials and briefly consider the technology of their installation.

Soft roofing has found wide application in individual construction. There are many reasons for this, one of which is the relative ease of installation. In this article, we will try to get acquainted with the most common materials and briefly consider the technology of their installation.

General characteristics of materials for soft roofs

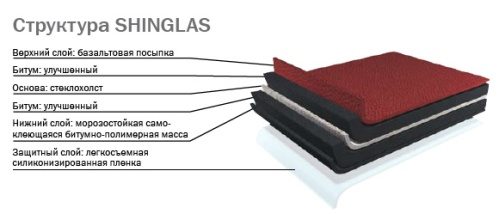

Soft roofing materials structurally consist of several layers. Typically these layers are:

- The base is made of fiberglass or fiberglass.

- Bituminous covering of a basis from two parties.

- The front surface (stone or mineral chips of different colors are most often used for it).

- The bottom surface may be formed by a layer of quartz sand or (in some cases) a self-adhesive layer.

Soft roofs are good for installing various types of pitched roofs, the slope of which is 11 degrees or more. The low thermal conductivity of these materials helps to prevent the appearance of snow and ice avalanches when the roofs warm up in the spring.

Popular soft roofing materials and manufacturers.

There are several manufacturers that are particularly popular among consumers. These include companies such as:

- CertainTeed, the world's largest roofing materials company. American soft roof has the widest range of colors and models in the world.

- IKOPAL is one of the oldest manufacturers of roofing materials. Coatings produced at the company's factories have high levels of protection against ultraviolet radiation, negative temperatures and moisture.

- Shinglas is a Russian plant and its Lithuanian partner, the Gargzhdu MIDA plant. A distinctive feature of the products of these factories is a five-layer construction with a self-adhesive bottom layer.

- Italian company Tegola. Due to the peculiarities of the composition and production technology, bituminous soft roofing, from an Italian manufacturer, retains its properties at temperatures from -70 to + 150 degrees Celsius. The material warranty is 15 years, and the service life can last up to 50 years.

- Finnish Ruflex materials are available in a wide range of colors and are presented on the market in several collections.The modified bitumen used in the manufacture of roofs from this manufacturer improves their climatic characteristics.

- Soft modern roof rubemast. This material is made by applying a covering material to a bitumen impregnated roofing board. In this case, the coating composition is applied in accordance with the requirements of TU 21-5744710-505-90.

Advice! Before you start laying a soft roof yourself, measure your strengths and capabilities. It may be the best way out for you to turn to experienced craftsmen in such works. If your decision is to do everything yourself, then check out the technology that is described below.

An example of soft roof laying technology

Before starting the roofing installation, it is necessary to prepare in advance the tool that will be needed in the work. This will save time on laying the coating.

There is no need to use expensive or scarce tools when performing such work. It is quite possible to get by with the usual set of tools that everyone has.

So, you need to prepare:

- Hacksaw.

- Hammer.

- Roulette (preferably at least five meters long).

- Sharply sharpened knife.

- Pencil.

In addition, you will need a trowel with which mastic is applied for a soft roof.

Preparatory work

After the material has been prepared and a soft bituminous roof has been purchased, preparatory work can begin. We start by preparing the foundation.

The surface intended for laying flexible tiles must be well leveled, cleaned and dried.Soft bituminous roofing is by no means laid on the crate like slate or profiled sheet. .

Therefore, a solid base is made of moisture-resistant plywood or OSB (oriented strand board). Here it is necessary to ensure the absence of deflections of the sheet material, otherwise do-it-yourself soft roof in these places it may eventually become unusable, and water leaks will appear.

Steam and waterproofing device

By itself, the construction of a soft roof copes well with the tasks of waterproofing, but additional protection measures are applied for insurance.

As a material for additional waterproofing, experts recommend choosing rolled material with a self-adhesive base. An example of such an insulator is a multilayer film based on polyethylene impregnated with a bitumen composition.

Waterproofing is laid in rows parallel to the cornice line. In this case, the vertical rows should overlap each other by at least 200 millimeters, and horizontally by at least 10 centimeters.

Nowadays, it is customary to lay a layer of insulation under all types of roofs, even such as rolled standard roof, but the formation of condensate contributes to the ingress of moisture into the insulation and reduce its heat-insulating properties. Thus, it becomes necessary to use a vapor barrier.

To do this, vapor-tight diffusion films are used. These films are laid under the insulation, placing rows along the rafters. Film joints should be located on the rafters.

Roof installation

As mentioned above, roofing materials are soft and do not present difficulties during their installation. It is only necessary to follow a certain sequence when laying.

We begin laying the first sheet and cornice row:

- The first sheet is laid along the cornice, for this the protective film is removed and mastic for soft roofing is applied to the coating.

- The sheet should be laid at a distance of 10 - 20 millimeters from the cornice bend.

- After that, the rest of the sheets in the first row are stacked in the same way. Laying should be carried out joint to joint and nail each sheet in the place where it is perforated.

We lay the remaining rows in the roof:

- By analogy with the previous row, remove the protective film from the sheets and apply mastic.

- We paste the sheets in the direction of the end part of the sheet of the first row.

- We nail the sheets.

- Excess coating along the edges of the roof and at the joints are cut off and treated with mastic.

Soft roofing - laying rows

We mount a soft roof on the roof ridge:

- According to the instructions, we divide the sheet of cornice tiles into three parts.

- We glue the sheet in the same way as before. The short side of the sheet is parallel to the roof ridge.

- We nail the glued sheets, placing the nails under the next sheet. The next sheet is stacked with the call to the previous stacked sheet.

Note! Soft roof - the materials from which it is made may have differences in shades in different packages. So that your roof does not look like a mosaic panel, it is better to immediately mix the sheets from different packages. In this case, the difference in shades will be less noticeable.

Additional roof elements

According to the results of many years of observations, the long service life of soft roofs is achieved only if they are properly ventilated.This is due to the fact that in the absence of ventilation, moisture accumulates in the roofing material and destroys it.

Therefore, during installation soft roof it is advisable to immediately install devices for forced ventilation of the insulation and under-roof space. Thus, you will ensure that you do not have problems with the roof for a long time.

As you can see, laying a soft roof is not difficult if you have minimal skills and the necessary tools. Enough desire and more or less "direct" hands.

The most important thing is to follow all the instructions exactly, and you will become the owner of a beautiful and practical roof. Soft roofing is your best choice!

Did the article help you?