Do-it-yourself roll roofing is not a complicated process, but laborious. Two people will be enough to complete the work. What material to choose and how to install this type of roofing is described in our article.

Do-it-yourself roll roofing is not a complicated process, but laborious. Two people will be enough to complete the work. What material to choose and how to install this type of roofing is described in our article.

Roll roofing is used for roofs whose slope angle is from 0 to 30%, that is, it can be a flat, single-pitched or multi-pitched surface. This type of roofing has been used for a long time.

Modern technologies have made it possible to improve the quality of the material and extend its service life. If earlier it was 5-10 years, now, depending on the type chosen, it has increased to 15-25 years. What are roll roofing materials?

This type of roofing is divided into two types:

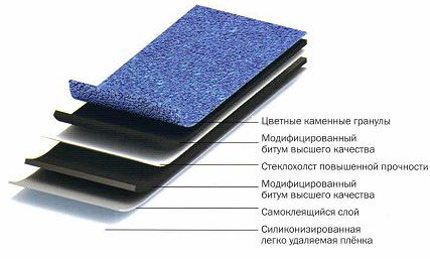

- Basic.They are obtained by processing the base (cardboard, fiberglass) with astringent organic mixtures (tar, bitumen). Depending on the binder composition used, they are divided into bitumen, bitumen-polymer, tar. According to the structure, they are divided into integumentary and integumentary.

- Baseless. They are made by heat treatment of binder mixtures with various additives and fillers, the resulting composition is then rolled into sheets.

Coating materials are coated on one or both sides with a layer of refractory bitumen with fillers and/or additives. The bloodless do not have such a layer, which is clear from their name. Conventionally, roll roofing materials can be divided into four generations:

- Glassine, cardboard-based roofing material. These materials appeared in Soviet times and are still popular as the cheapest type of roofing. But, their service life is short, only 3-5 years, and at least three layers will have to be laid.

- Rubemast is a built-up roofing material. A slightly improved version of the previous material. Although nothing has changed in terms of service life and the number of layers, the installation of this type of coating will take much less time than laying a simple roofing material.

- Glass roofing material. As a basis, instead of roofing paper, fiberglass or polyester is used. This is a more modern and reliable option. Due to the non-rotting base, the service life of the coating increases to 12-15 years. Built-up euroroofing material. Currently enjoys popularity in many regions of our country. This material is not afraid of sudden changes in temperature and great frosts. The number of roofing layers has been reduced to 2-3, and the service life has been increased to 25-30 years.

- Membrane roll coating, the most modern material.Differs in speed of installation and durability. You can also use self-adhesive materials. Under the influence of solar heat, the adhesive properties of the coating are activated, that is, the material is rolled out on the roof on a sunny day, and it sticks itself. Just remember to first remove the protective film from the bottom. Everything is simple, though it is expensive, but you don’t have to spend money on nails and mastics.

Roll roofing materials, in particular roofing material, has an alphabetic and numerical designation. They can be identified as follows:

- The name of the material is roofing material (P).

- Type of material - lining (P), roofing (K), elastic (E).

- The type of external dressing is scaly mica (Ch), fine-grained (M), pulverized (P) and coarse-grained (K).

- The brand number that indicates the weight of the cardboard in grams per 1m2. Accordingly, the higher this value, the stronger the material.

For your information: sometimes the letter “O” is used in the designation, what does it mean? It indicates that the roofing material has a one-sided dressing, the top one.

As can be understood from the letter designation, roll roofing materials are used in different conditions. So, for example, lining roofing felt can only be used for laying the lower layers of the carpet, and roofing, only from above.

Accordingly, their characteristics will be different. The top layer takes on the main impact (ultraviolet, moisture, etc.), therefore, it must be more durable.

Roofing material can be fixed in several ways:

- Mechanical - with the help of roofing nails. Usually it is used when installing the lining layer. A metal tile or a flexible roof is then laid on top.

- Gluing on a layer of bituminous mastic. It is used when installing roofing materials of the first - third generation. Moreover, all layers are laid in this way, regardless of the lining or top.

- Welding with a gas burner. It is used for the built-up materials, euroroofing material.

It's no secret that every person chooses the rolled roofing material that he can afford. And even if you buy not very expensive material, but correctly complete all the stages of installation, and then eliminate defects in a timely manner, the roof will last much longer than it says in the instructions.

Installation of a rolled roof

Soft roofing is rolled, depending on the angle of the roof slope, it is laid in several layers:

- 0-5% - 4 layers. . In multi-storey buildings, the roofs are almost flat, so it is recommended to lay at least 5 layers.

- With a slope of 5-15%, three layers will be enough.

- If the slope is more than 15%, you can limit yourself to two layers of roofing material or perform soft tile roofing.

Attention! This information applies to the latest generation of roll coating. Ordinary roofing material should be laid in at least three layers. Also, do not forget about the features of a particular type of roof. Before starting work, it is recommended to consult with specialists.

Before proceeding with the description of the order of work, I would like to focus on bituminous mastics. They are of two types: hot and cold. Usually they are cooked on their own.

For this you will need:

- Cold mastic - bitumen (40%), diesel fuel or kerosene (40%), and fillers (crushed asbestos, slaked lime) 20%.It is prepared like this: refractory bitumen is loaded into the container, not in large pieces, and heated to a temperature of 160-180 degrees, after which it is dehydrated. At the same time, kerosene and fillers are mixed in another container. After that, the contents of the second boiler are poured into the first and thoroughly mixed until foaming stops and the mastic becomes homogeneous.

- Hot mastic - bitumen (80-90%) and fillers (10-20%). Bitumen is heated in the tank to a temperature of 200-220 degrees. Then gradually add the filler. When foam appears, the floating, undissolved particles are removed with a “net”. Stir until the mass becomes homogeneous, with a mirror surface. The mastic should cool to 160 degrees, after which it can be used.

What else should you know before starting the installation of roofing from rolled materials? If the roof is flat (up to 15% slope), the roll roof is laid parallel to the ridge.

The first panel is spread along the edge, with a bypass on the cornice overhang (10-12 cm). Then this edge is fixed on the cornice with a pressure board and nails. Subsequent rows are overlapped (at least 10 cm).

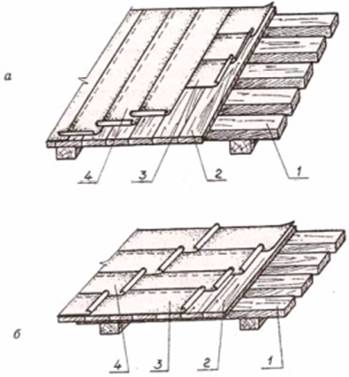

With a slope of more than 15%, the panels are laid across the ridge. To do this, triangular bars 50x50x70 mm are stuffed onto the crate, the distance between them should be 10 cm less than the width of the roll of the material used.

In this gap, the roofing is laid, the edges of which should evenly lie on the bars. The lower edge should go down to the overhang (10-12 cm), and the upper one should be thrown over the ridge.

Cloths on soft top they are nailed with roofing nails in increments of 50 cm. After that, caps are cut (strips 12 cm wide), which are folded in half.They cover the bars, and everything is fixed with roofing nails.

For your information! Before starting work, roofing roll materials are laid out on a flat surface for alignment. At the same time, “shooting” is done, they look to ensure that the overlap along the entire length is the same.

Roll soft roof consists of the following layers:

- Crate.

- Vapor barrier (painted and glued).

- Insulation layer.

- Screed.

- Roll materials.

- Top powder.

The device of a rolled roof begins with the preparation of the base (battens). Reinforced concrete slabs are rubbed with cement, this applies to flat roofs.

For pitched roofs, a crate is made of OSB boards, moisture-resistant plywood or edged boards. Of these, a solid surface is mounted. Before starting work, wooden materials are treated with a protective compound.

Vapor barrier is a layer of cold or hot bituminous mastic. Its height should be 2mm. After its application, the bitumen is allowed to harden.

For flat roofs, a layer of gravel is used as a heater, a cement screed is poured on top. Insulation can be not only loose, but also monolithic and slab, that is, other heat-insulating materials are used.

The height of the screed depends on which insulation was chosen: loose - 3 cm, slab - 2 cm, monolithic 1 cm. In the first hours after the installation of the screed, the surface is primed with bitumen. It forms a film that will prevent the evaporation of water from the cement.

Laying of roofing material starts from the bottom (parallel laying) or from the edges (transverse laying). The subsequent rows are overlapped: 10 cm wide, 20 cm long. After applying the first layer, it is recommended to take a break for 12 hours.

During this time, defects (bloating, blisters) will appear, which are immediately eliminated.Subsequent layers are stacked in a checkerboard pattern so that the joint of the lower layer does not coincide with the seam of the upper one. After laying all the layers, the roof is coated with bituminous mastic. A special topping is poured on top of it and rolled with a roller.

Roll roof repair is divided into two types: current and capital. Current repairs are scheduled if damage to the roof cover is less than 40% of the entire roof area.

If there are more problem areas, the roof is overhauled. That is, they completely change the roofing.

But, if you do not let things take their course, but repair the rolled roof in a timely manner, the roof will last a long time and will not leak.

Indeed, sometimes it is enough to re-walk with bituminous mastic in problem areas or partially replace the roofing carpet, well, in extreme cases, replace the top layer (it becomes unusable before the other layers). Repairing is still easier than laying again.

Did the article help you?