Like any technological process that is becoming widespread, the construction of a new house is becoming more and more simplified every day. This also applies to the creation of roofing - if earlier, to create a high-quality roof, it was necessary to assemble a single sheet from its individual elements for a long time, now, to achieve the same result, you can easily and simply glue a single layer of roofing, assembled for convenience into a single roll . This technology is quite new for the domestic market, so in this article we will try to shed light on the installation of roofing from rolled materials.

Like any technological process that is becoming widespread, the construction of a new house is becoming more and more simplified every day. This also applies to the creation of roofing - if earlier, to create a high-quality roof, it was necessary to assemble a single sheet from its individual elements for a long time, now, to achieve the same result, you can easily and simply glue a single layer of roofing, assembled for convenience into a single roll . This technology is quite new for the domestic market, so in this article we will try to shed light on the installation of roofing from rolled materials.

Types of roll materials

On the modern building materials market, there are countless of the most diverse types of roofing sold in rolls. They can be roughly divided into three categories based on soft roof technology.

- Adhesive. Such laying of rolled roofing is the simplest; various hot or cold mastics, as well as special glue, can be used to apply a layer of roofing material.

- With adhesive layer. The technology of laying a soft roof in this way implies that a layer of glue is initially applied to the inside of the coating, therefore, to lay such a roof, it is enough to simply remove the protective coating from the adhesive layer and fix the roofing material on the roof surface.

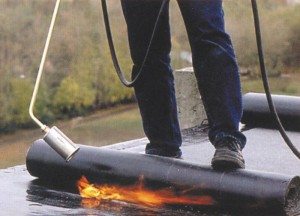

- Built-up. The technology for applying such a coating is somewhat more complicated than the previous ones, however, it will also hold on much stronger and longer. Such roofing materials are applied using gas burners, as well as some fireless methods.

In addition, modern rolled roofing materials can be both basic and baseless.

- The design of the main roofing materials already includes a pre-prepared base made of cardboard, asbestos or fiberglass, treated with special reinforcing impregnations, which may include tar, bitumen and various hybrid mixtures.

- Baseless coating is simply a roll of roofing material of a given thickness. Such a coating during application requires the use of additional mixtures of binders, fillers and various specific additives.

Roll roof properties

Roll roofing has a number of advantages over more traditional roof coverings.

Among them:

- Ease of application. This factor is often decisive when choosing a rolled roofing. Many people may not have the time or opportunity to assemble a conventional roof, while creating a cover by gluing a roll of special material is very simple and fast.

- Good sound and heat insulation. When creating a traditional roof, these parameters are regulated by creating a protective layer under the roof, in this case, the roofing itself already initially has sufficient insulating properties.

- Flexibility and tensile strength. Modern roofing roll materials are made using a special technology and are too soft to be afraid of the mechanical damage that harder roofing materials are prone to. Such a coating will not crumble, break and undergo various kinds of corrosion.

However, it has such a coating and several disadvantages, which are primarily due to the characteristics of the materials used:

- Brittleness at low temperatures. This property is the biggest disadvantage of modern roll coatings made from materials designed for a favorable climate.

- Impossibility of installation in the winter. A feature that follows directly from the previous paragraph. In order for the made roof to survive more than one winter, you will have to wait for the most favorable conditions for the correct and thoughtful assembly of the roof.

- Comparative durability. This item also originates from the poor frost resistance of the materials used.Constant temperature fluctuations do not have the best effect on soft roofing, reducing its effective service life to 5-10 years.

Thus, modern roll roofs are intended primarily for use in mild climates, as well as in houses where changing the roof covering is a fairly simple process and is performed at a predetermined frequency.

Fortunately, modern rolled roofing has all the necessary qualities for this.

Application of roll roofing

The process of creating a high-quality coating from rolled materials can be divided into several steps:

- Foundation preparation. At this stage, the roof surface is cleaned and prepared for the application of the roofing layer.

- Application of roll materials. The necessary layer of roofing material is applied to the cleaned and prepared surface by gluing or fusing.

- Finishing of joints. For the greatest efficiency and durability of the rolled roof, immediately after the application of the roofing material, the joints of the individual sheets of the coating should be correctly and reliably sealed.

- Application of paint and protective layers. At the final stage of work, the roof surface is given the necessary appearance, as well as various additional coatings are applied to enhance the useful properties of the roof.

Preparatory work includes the most thorough cleaning of the area necessary for applying the desired roofing from various third-party inclusions and physical defects.

These include the remains of the previous coating, all sorts of bumps and cracks, as well as stains and dirt.

Attention! After cleaning, the roof surface is covered with an even layer of primer for better adhesion to the roofing material.

After that, you can proceed to the direct application of a layer of roll material.

It all depends on the type of coating chosen. For some types of materials, it is enough to remove the protective coating from the adhesive layer before application, while others require the use of a torch for soft roofing.

Advice! Whatever method of applying the coating material is chosen, the procedure for mounting the roof must be carried out with all care and caution.

There are several ways to apply a layer of roll materials. You can manually adjust and glue each sheet of coating, carefully monitoring the joints and quality of laying. This method is very long, but its result will be much more accurate.

You can also use various modern devices for mechanized application of rolled materials. This option is much faster, but it is somewhat more difficult to control the quality of the coating during such application.

Thus, it is necessary to choose between efficiency and control. However, depending on the specific conditions, these methods can be combined. In addition, in some cases, special devices simply cannot be dispensed with.

These conditions include both welded rolled roofing materials and gluing the coating over large areas where manual labor is simply impractical.

After applying a layer of roofing material, the turn of the most sensitive areas of the coating comes. These include, in particular, the junction of the individual sheets of the rolled coating.

The slope of the rolled roof can be very slight, so the liquid that gets onto the roof from precipitation does not always flow down, but slowly accumulates on the surface and can flow into various unprotected places.

Therefore, securely sealed joints are absolutely necessary for the effective and durable service of a soft roof.

When all the most difficult areas of the coating are completely protected from any external threats, you can start applying a protective and decorative coating. As noted earlier, the roll materials used for roofing are very sensitive to sudden changes in temperature.

That is why, in most cases, before the final coat of paint, several special layers and impregnations are applied to the roof, designed to provide additional protection from excessive cold.

At the last stage of applying the roof, a decorative finish of the resulting coating is performed. It all depends on the tastes and preferences of the owners of the house or the organizer of the work. Initially, the roofing in rolls has a neutral color, corresponding to the materials included in its composition.

However, with the help of special paints, you can give it any appearance that will meet the given style or goals. There are a lot of ways to give the roof the necessary color and texture, everyone will find the most acceptable for themselves.

In a word, rolled roofs are the best way to quickly create a fairly reliable and convenient coating for your own house, cottage or any other building with a flat roof.

To apply such a layer, no specific knowledge and skills are required, so an amateur can handle it. What makes rolled materials a simple and affordable coating option.

Breathable roofs

The device of a rolled roof involves a dense application of a single layer of roofing material on the roof surface. This method is very convenient and practical, but it also has some disadvantages.

Sooner or later, a certain amount of condensate accumulates under a continuous coating, which does not have a very good effect on the overall physical properties of both the coating itself and the materials under it.

To eliminate such problems, the so-called breathing roof technology was invented - its peculiarity lies in the fact that the adhesive coating is not applied in a continuous layer, but with specially created gaps, due to which air bags are created under the roofing material.

This technology of the roll roof device allows to ensure sufficient ventilation of the space inside the roofing, thus eliminating the problems associated with the appearance of condensate and dampness.

However, for all their usefulness, such breathable roofs also have their drawbacks, one of which can be difficult minor repairs of soft roofs, because water circulating through air tunnels can get inside from anywhere, so such a system can somewhat complicate finding the place of a possible leak.

Therefore, the choice of a roof that uses breathable roof technology should be approached with particular care.

Thus, roofs based on rolled materials have their own characteristics that distinguish them from traditional hard roofing.Thanks to these features, this type of soft roofs is confidently gaining its place in the modern building materials market.

Did the article help you?