In this article, you can get acquainted with the options for installing a soft roof with your own hands. The proposed instructions for laying tiles and roofing material will be useful to both owners of country houses and residents of the last floors of multi-apartment buildings.

When laying the roof yourself, you should not forget about reliable waterproofing - this moment is one of the first to think about. - bitumen-polymer mastic. It is it that is applied to insulate the roof. The client can choose the necessary option in the online store of TP Protect LLC.

Choosing roofing materials

Not so long ago, soft roofing materials were used exclusively in the construction of high-rise buildings. Today, both flat and gable roofs of low-rise individual buildings are lined with rolled coatings and bituminous tiles.

Advantages:

- Lightweight materials - it is possible to reduce the mechanical load on the truss system;

- Shorter terms and lower labor intensity of laying - you can lay the roof not only quickly, but also with your own hands, without involving professional installers;

- Attractive end result price - soft roofing materials, subject to the right choice, cost less than traditional hard counterparts, and do not forget that all the work can be done by yourself;

- Long service life and high maintainability - repairing a soft roof is much easier than slate or tile flooring;

- Installation of roofing systems with complex architectural forms - soft roofing materials are much easier to lay on curved surfaces than to do the same work with slate, ceramic tiles or corrugated board.

Do-it-yourself roofing can be made from the following materials:

- Bituminous tiles.

In the manufacture of this roofing, fiberglass is impregnated with a modified bitumen, after which the workpiece is covered with a layer of colored stone granulate.

Flexible tiles are characterized by zero water absorption and absolute resistance to decay and corrosion processes. The tile is less elastic compared to rolled materials, but this characteristic is compensated by its smaller size.

As a result, the violation of integrity during the aging of the roof affects the individual fragments of the coating, which can be easily replaced.

Externally, flexible tiles do not look as impressive as ceramic ones, but this disadvantage is compensated by a wide range of colors, which means that you can choose the design of the roof in accordance with the facade finish.

- Roll covers.

Despite the variety of roll coatings, they can all be divided into two types: roofing felt and roofing felt.

Ruberoid is made by impregnating roofing paper or fiberglass with bitumen, followed by sprinkling with stone granulate. The composition of the material is similar to the composition of bituminous tiles with the difference that the roofing material has a smaller thickness with greater elasticity.

The material is sold in rolls, therefore, to prevent sticking of the sheet, asbestos bedding is used in the coils. Among the shortcomings of the material, low resistance to mechanical stress and flammability should be noted.

Many people ask what is better - roofing material or Linocrom, Rubemast, etc.? Such questions are not correct, since Linocrom, Rubemast and similar materials are commercial names for roofing material.

Roofing felt is a roofing material, less common in comparison with roofing material. The coating is made from roofing paper, which is impregnated with coal tar, followed by sprinkling with granulate.

Roofing felt is characterized by a smaller thickness in comparison with roofing felt, and therefore is used for laying a soft roof of outbuildings or as a lining layer for subsequent roofing felt flooring.

Tiling - step by step description

Prepare the following tool:

- Mounting knife with a straight blade;

- Mounting knife with a curved blade;

- Measuring tool (tape measure, folding rule, marker);

- Tinted lace (chopping);

- Construction pistol;

- Metal spatula of medium width for applying mastic;

- Building hair dryer;

- Scissors for metal straight;

- Screwdriver.

From the materials you will need:

- Bituminous tiles;

- Tin strips - aprons;

- Vapor barrier membrane;

- Thermal insulation material;

- Steam diffusion film;

- Bar with a section of 50 × 50 mm;

- chipboard or plywood;

- Gutter holders;

- Roofing nails;

- Bituminous sealant;

- Planks for arranging the junction of the chimney.

Installation instructions for bituminous tiles:

| Illustration | Stage description |

| Preparatory processing. Before making a roof, we process the wooden elements of the truss system with antiseptics and flame retardants. Impregnation treatment is carried out in several layers with a break for complete drying of the previous layer.

. |

| Vapor barrier installation. The truss system of a gable roof from the side of the attic is covered with a vapor barrier film.

The film is rolled out in horizontal stripes from top to bottom so that the lower strips overlap the top ones with an overlap of up to 15 cm. This arrangement of the vapor barrier will prevent the passage of moist air from the inside into the thermal insulation layer. |

| Insulation bookmark. In the gaps between the rafter legs we lay mineral wool slabs. The layer thickness for the temperate climate zone is at least 200 mm.

In order to prevent the appearance of cold bridges, thermal insulation should be laid in 2 layers, with the upper layer offset relative to the lower layer. |

| Laying the vapor diffusion layer. On top of the laid insulation, we roll out the vapor-diffusion material from top to bottom.

As a result, the upper strips should overlap the lower ones with an overlap of 10-15 cm. The edge of the material along the overlap line is glued with double-sided tape. The material is fixed on the rafters with a stapler. |

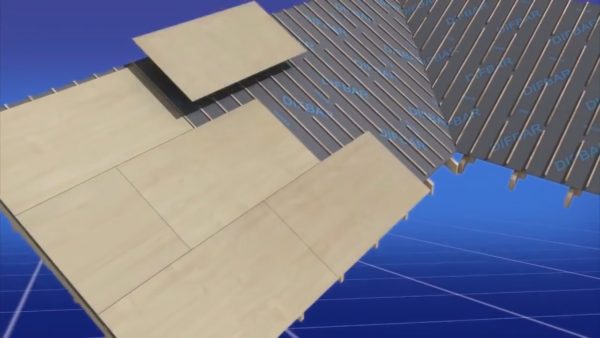

| Ventilation chamber device. On top of the vapor diffusion material, bars with a section of 50 × 50 mm are stuffed onto the rafter legs.

A gap of 50 mm in height is needed so that the steam that has penetrated the insulation from below comes out up. |

| Base mounting. Oriented strand boards or thick moisture-resistant plywood are attached to the previously installed bars, in a run-up.

We fix the plates with self-tapping screws. Between the plates we maintain a compensation gap of 1-2 mm. |

| Installation of gutter system holders. Along the edge of the cornice overhang, with a step of 60 cm, brackets are installed - drain holders.

In the previously laid base, potai are cut out to the width and thickness of the holder. The ends of the holders are laid in potai and fastened there with self-tapping screws. |

| Installation of aprons. We fasten the aprons with a projection of 20-30 mm from the edge of the bottom plate and fix them with self-tapping screws in increments of 30-35 cm.

We overlap the planks of aprons at the joints, treating the joined areas with silicone sealant. |

| Installation of waterproofing. The waterproofing membrane is laid along the roof base, starting from the eaves with an overlap on the upper part of the apron.

The upper strip is laid with an overlap of 15-20 cm on the lower one. Dense waterproofing is attached to the base plates with nails. The membrane with a small thickness is attached with a stapler. |

| Membrane overlap sealing. During the laying of waterproofing, joints, without fail, are glued with bituminous sealant. |

| Roof marking. In the course of marking, the center of the slope is determined, along which the vertical center line is beaten off.

From the vertical level, horizontal lines are marked to the width of the laying of the roofing material with which they decided to cover the roof. |

| Installation of the first row of roofing material. We cut a strip of cornice tiles with a mounting knife.

With the help of bituminous sealant and roofing nails, we fasten the first strip, stepping back 20 mm from the edge of the previously installed apron. |

| Installation of soft tiles. The next strips of tiles are superimposed with rectangular ledges on the first strip.

Rectangular ledges of tiles are fixed with bituminous sealant. The main strip in the upper part is fixed with roofing nails with a wide head. |

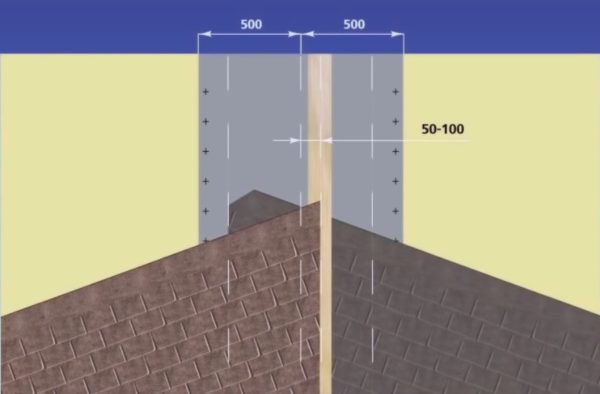

| Laying soft tiles in the valley area. The valley is marked as shown in the diagram:

|

| Tiling on a ridge element. Previously cut rectangular fragments of tiles are laid on the ridge elements. These fragments are installed with an overlap, that is, the upper fragment of the coating comes over the lower fragment. Fastening is carried out on bituminous sealant and on two nails in the upper part. |

| Strengthening the contact of tiles with the base. To make the bituminous coating more durable, when laying its fragments on sealants, immediately heat the surface with a building hair dryer.

As a result, the glue will be evenly distributed over the entire contact surface, and in addition, the adhesion of the glue will be improved. |

| Installation of junction of ventilation or chimney pipes.

For the junction device, special elastic casings are used, the lower part of which is glued with sealant along the perimeter of the hole to the tile. The casing is additionally attached to the roof with self-tapping screws. |

| Installation of abutting brick pipes. For a tight connection, the waterproofing membrane, together with the tiles, is placed on the chimney, as shown in the photo.

Roofing materials are pressed against chimney metal apron. The connection between the apron and the chimney is sealed with bitumen. |

How roofing felt is laid

Consider the instructions for laying a soft roof using roofing felt on a garage roof. Roof repairs on multi-storey buildings are also carried out.

You will need:

- Built-up roofing material;

- Bituminous mastic for high-quality gluing of seams;

- Cement-sand mixture for concrete preparation.

In the instructions I will tell you how to work with built-up roofing material. Please note that the use of such material allows you to complete the job faster and with less labor. For the installation of a conventional roofing material, the surface is pre-coated with bituminous mastic. This method is complex and therefore rarely used.

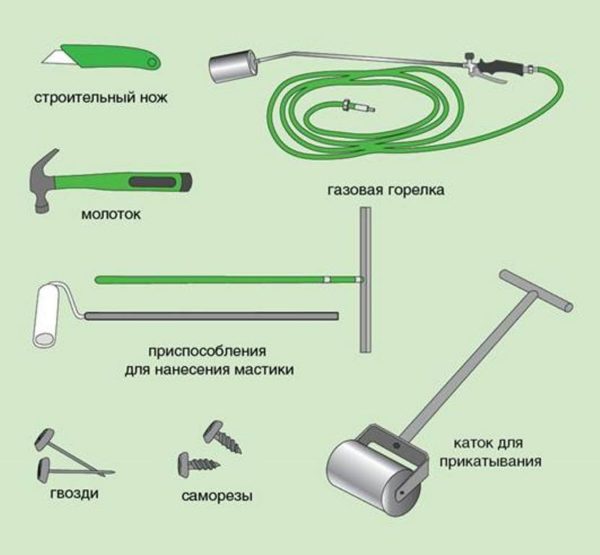

You will need the following tool:

- Gas burner or powerful building hair dryer;

- Ax and perforator with a chisel;

- Mounting knife;

- Measuring tool;

- Special roller for rolling roofing material;

If there is no roller, you can level the coating with your weight by stepping on the surface.

- Capacity and tools for concrete preparation;

- Rule and master.

Instructions for laying roofing material:

Conclusion

Now you know how to line the roof with a soft roof. If the proposed instructions were interesting and useful, write about it in the comments.There you can also ask questions on the topic - I guarantee exhaustive explanations.

I recommend watching the video in this article, I'm sure you will be interested.

Did the article help you?