How to enclose and protect a container site from rain, wind and sun? In this article, we have to analyze one very specific solution - a fence with a canopy made of a profile pipe and a profile steel sheet. So let's get started.

Requirements

What do we want from a fence with a canopy?

- Canopy for trash cans should provide protection from snow and rain. Dampness will accelerate the corrosion of steel tank walls; in plastic, an unappetizing cocktail of rotting waste is formed.

- All structural elements must be vandal-proof. Alas, the world is not perfect; the population of the country consists not only of well-educated intellectuals.Actually, that is why we have chosen a steel frame with metal sheathing.

To clarify: in terms of strength, an ordinary steel sheet is no worse. However, the profiled sheet attracts by the fact that it is already equipped with a protective anti-corrosion coating. In addition, corrugation provides maximum rigidity with minimum sheet weight.

- The fence should protect the tanks from the wind. Otherwise, light debris will have to be collected within a kilometer radius from the site.

- Ideally, closing doors will not interfere, which will not allow stray animals to ruin the tanks. In addition to the garbage that large dogs often pull out onto the site, do not forget about banal safety. Dog attacks on humans are not uncommon; often they occur in cases where a person disputes, from the point of view of the dog, the right to own his food supply.

Go shopping

What kind of materials will be needed for a canopy and fencing?

Proftruba

Its cross section depends on what structural element we are going to make.

| Structural element | Minimum pipe size, mm |

| Corner posts | 60x60 |

| beams | 60x60 |

| Door frame | 40x40 |

| Jumpers (stiffening ribs) | 20x40 |

profiled sheet

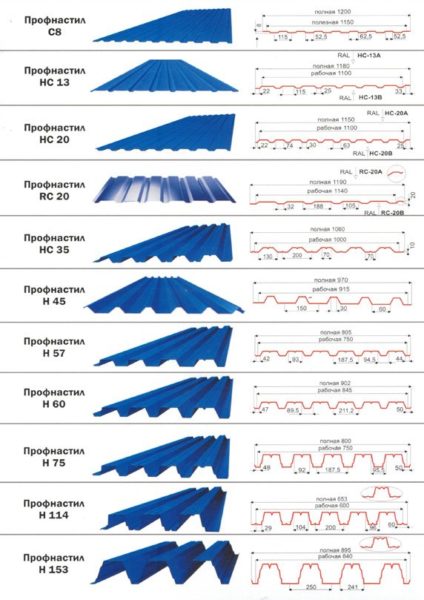

How to choose a professional sheet? It should be marked as C (wall) or HC (bearing - wall). In the second case, the price of the sheet will be noticeably higher: the use for self-supporting structures implies higher strength.

A reasonable minimum thickness is 0.7 mm. A sheet with a thickness of 0.4 mm will not be anti-vandal in any way: even an accidental blow will leave a noticeable dent on it.

Wave height - from 20 mm for the same reasons.The larger the value of this parameter, the stiffer the sheet.

The type of coating (galvanized or polymer paint) is a matter of taste. Zinc is cheaper; in addition, it is somewhat more difficult to damage. But the polymer coating offers a large selection of colors, and it looks much more attractive.

Area

It can be either a ready-made road slab laid on a sandy substrate or a reinforced platform poured in place.

In addition, the canopy can be built on an asphalt or dirt base.

Instructions for filling the site with your own hands looks like this:

- The soil is removed to a depth of about 20 cm. The bottom of the mini-pit is leveled.

- Then the bottom is covered with sand by 10 centimeters. The sand is rammed or spilled for maximum shrinkage with plenty of water.

- A layer of polyethylene or roofing material is laid on top of the bedding. It will prevent the cement milk from going into the sand.

- Reinforcing mesh is laid on stands about 5 cm high. Wire thickness - 5-6 mm, cell size - 10-15 cm.

- Concrete of the M200 brand is laid out on top of the reinforcement (1 part of M400 cement; 2.8 parts of sand; 4.8 parts of crushed stone), carefully bayoneted and leveled with the rule. The thickness of the future plate is about 10 cm.

It takes about a month to set branded strength with concrete. In extreme heat for the first week, its surface is covered with polyethylene, burlap or straw; as an option - concrete is wetted with water every 1-2 days.

pillars

Their installation on a concrete base looks like this:

- A platform made of steel sheet is welded onto the end of the column. Size - 150x150x4 mm.

- Four holes are drilled in each area at the corners.

- The column is anchored to concrete.

Important: the minimum distance from the anchors to the edge of the concrete is 10 cm. Otherwise, there is a risk of chipping off the edge.

On a soil base, the pillars are concreted in pits:

- A garden drill drills a well with a depth of 0.5 - 0.7 meters.

- Its bottom is covered with 10 centimeters of rubble.

- The column, covered below the ground level with bituminous mastic, is installed on a plumb line and covered with crushed stone with layer-by-layer tamping every 20 cm.

- Crushed stone is poured with a liquid cement-sand mortar, prepared in a ratio of 1: 3.

frame

There are few subtleties in its construction.

- On the side of the casing fastening, the surface of all pipes must be in the same plane.

- Jumpers from a thin (20x40) pipe are oriented with a narrow side (20 mm) to the sheet for more structural rigidity.

- The doors are assembled on tacks and straightened on a flat horizontal surface before welding the joints. For editing, it is enough to measure both diagonals of the frame: their length must match.

For painting the frame, domestic alkyd enamel PF-115 is usually used on the primer GF-021. The durability of the paint depends linearly on the quality of the preliminary cleaning of the surface. For it, a metal brush is used - manual or made in the form of a nozzle for a power tool.

sheathing

The profiled sheet is attached to the frame with metal screws with press washers. Of course, this work is done with an electric screwdriver. And here it is worth mentioning a few subtleties.

- Sheets are attached with an overlap in one wave.

- When using a sheet thinner than 0.7 mm, each wave is attached with a self-tapping screw. If you take a step less often, in windy weather the sheet will vibrate, making rather unpleasant sounds.

- It is undesirable to cut the profiled sheet in place. The cut will rust.

Conclusion

Of course, the solution we described is far from the only one. The reader will be able to study someone else's experience and peep a few original ideas by watching the video in this article. Good luck!

Did the article help you?